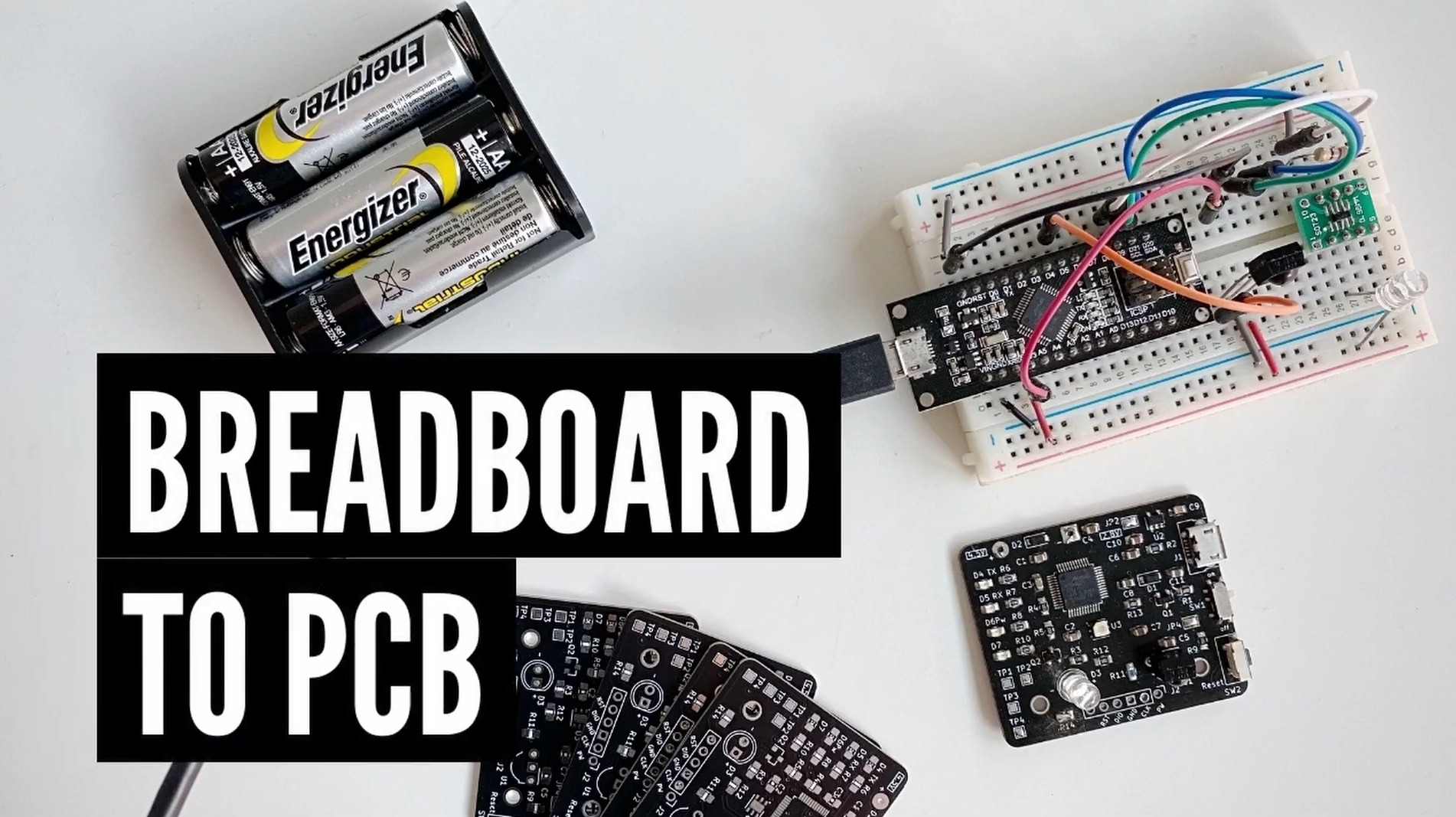

How do I convert my Arduino project to my own custom PCB? - LogiqBit How do I convert my Arduino project to my own custom PCB? Posted on December 15, 2021 | Ben So you're at the stage where you've got a working project and now you want to turn it into its own PCB. Maybe you're thinking of making a commercial product? How can I convert my Arduino Project into a PCB? k1234567891234532 January 6, 2022, 9:11pm 1 I'm using the following components in a remote sized 3d printed object. I've tried to minimize the size however there are still tons of wires everywhere which make things too big.

How do I convert my Arduino project to my own custom PCB? LogiqBit

2.1 Step # 1 - Designing the Ideal Microcontroller Circuit for Your Prototype 2.2 Step # 2 - Designing the Custom Schematic Circuits for Your Preferred Arduino Shields 2.3 Step # 3 - Designing the PCB For Your Prototype 2.4 Step # 4 - Placing an Order and Buying Your First PCB Prototype Step #1 - Design the Microcontroller Circuit The Arduino is a microcontroller development kit, so the first step is designing a custom microcontroller schematic to replace the Arduino. And the first step of designing a microcontroller schematic, is to select the microcontroller. How to Turn Arduino Prototype into PCB Production You may want to think about utilizing Arduino to build a PCB and prototype your idea for three important reasons. The simplicity with which Arduinos can be used is the first factor. No matter how big or little your project is, ease of use is crucial for the whole product development lifecycle. The best thing to do is, of course, to use a PCB. But it doesn't need to be a custom PCB; there are plenty of pre-made PCBs that are usable for approximately 98% of designs. Here are just a few: Adafruit Perma-Proto boards are connected just like breadboards, so direct transfer is possible.

Convert Arduino Like Electronics Projects to PCB At Home

In this video I will show you how to turn you breadboard prototype into custom printed circuit board.It contain a short Tutorial on how to use Fritzing softw. Use PCB drill to make holes from copper layered side. Place the components on copper-free side and test. Add some epoxy based glue on the surface of the bigger components which will remain in contact with PCB (that is a trick). Stick the components on copper-free side and forget for 8 hours. From an Arduino Prototype to a Commercial Product An overview guide on key questions/tools required to move your Arduino project to production board and a commercial product. So you have created a working prototype. What are the next steps in moving from an Arduino Prototype into an actual product? My first Arduino project: I have made a headlight sensor that will activate an outside light when a car's headlights hit it. I know I could go buy one, but where is the fun in that?. I'd recommend you transfer the whole thing to 'veroboard' (stripboard) rather than make a PCB. Veroboard/stripboard will be much quicker and cheaper. You could.

DFT Audio Analyser Arduino Project Hub

Discover the steps required to transition both the hardware and firmware from an Arduino Mega based protype to a fully custom PCB that can be mass produced. Published on August 30, 2022. It's no surprise that for larger projects with many peripherals or heavy GPIO requirements, the Arduino Mega is a popular choice for an electronics device. Step 7: Program the Arduino (using FTDI Breakout Board) Connect the breakout board to the arduino and connect that to the computer. Open device manager and observe the com port of the usb to ttl converter. In arduino IDE select the com port and board correctly. Now here comes a tricky part.

Using EasyEDA, you can transfer your files straight to JLCPCB, who in turn will make the PCB, sell you SMT components, assemble those components on the board and custom 3D print an enclosure for it. Currently you can get 5 PCB's for $2 USD. Component prices are the cheapest you will find. 1 Hey, I've got a two-part series ( arduino.stackexchange.com/q/207/6, arduino.stackexchange.com/q/221/6) on transitioning from the Arduino to plain ATmega development. It may be a nice idea to add this question to the series as the new part 1, since it's one of the important steps of shifting to atmega. Want to do that? - Manishearth

Design considerations for transferring a breadboard prototype to custom

First is what voltage and current are needed, which will be defined by your other components (e.g. if Component X needs 100mA at 5V and Component Y needs 200mA at 5V, I should put in a regulator that can supply at least 400mA at 5V so I have some breathing room). The next consideration is heat/efficiency. How Does It Work? The basic idea of shrinking an Arduino project is to make a permanent circuit board for it. This is done by programming an Atmega chip using an Arduino. To program an Atmega using Arduino, first of all, we need to make a DIY programmer and burn bootloader.