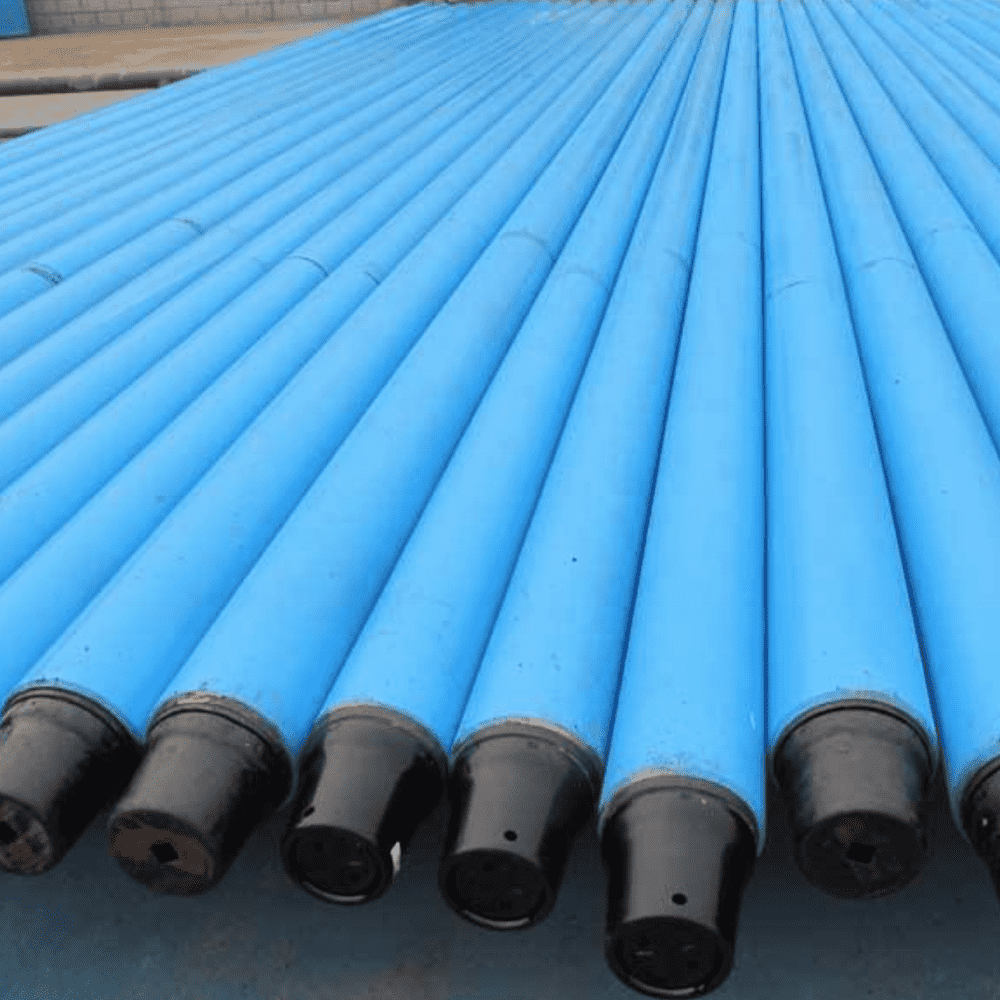

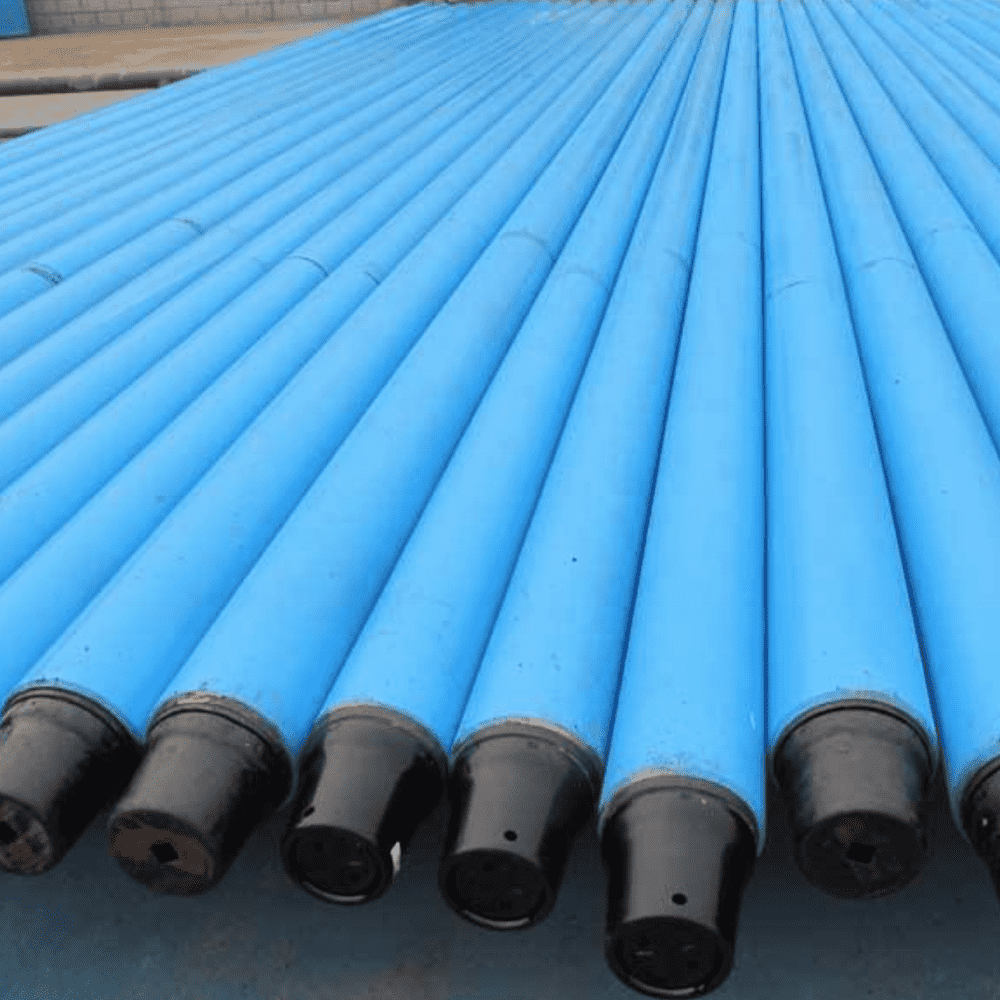

Drilling Collar Types Anti-wall stick / Spiral Drill Collar Square Type Non-Magnetic Type API Drill Collar Make-Up Torque Lifting & Making Up Facilities For Drill Collars Neutral Point API Drilling Collar Selections References & Related Papers Our drill collars are furnished as slick or spiraled; spiraled drill collars have grooves machined in the outside surface that promote the even flow of drilling fluid around the drill collar diameter, equalizing pressure and reducing the occurrence of differential sticking. Drill collar materials

Drill Collars Hunan Great Steel Pipe Co., Ltd.

In this article, we will explore three main types of drill collars: smooth drill collars, spiral drill collars, and non magnetic drill collars. We will also provide guidelines to help you choose the drill collar that best suits your specific needs. 1.Slick Drill Collars: Slick drill collars are smooth, without any spiral grooves or blades. DRILL COLLARS NON-MAGNETIC DRILL COLLARS When drilling in areas closer to the earth's magnetic poles, it is essential to use a non-magnetic drill collar. Drilling Tools International's non-mag drill collars ofer strength and hardness while neutralizing magnetic interference. There are two main types of drill collars, slick or spiral grooved, however, both styles accomplish the same task. Spiral groove drill collars were introduced in more recent years and are thought to help prevent the drill string from getting stuck in the hole by allowing drilling debris and lubricant to pass more freely around the drill collar. Drill collars are a component of the drill string that makes up part of the bottom hole assembly (BHA). They are thicker-walled, heavier, and more rigid than drill pipes and are primarily used to weigh down the drill bit while dampening vibration and impact forces. Drill collars are typically machined from solid carbon steel bar stock.

Drill collarDetailed Data Shanxi North Fenglei Industry Group Co.,Ltd.

drill collar 1. n. [Drilling] A component of a drillstring that provides weight on bit for drilling. Drill collars are thick-walled tubular pieces machined from solid bars of steel, usually plain carbon steel but sometimes of nonmagnetic nickel-copper alloy or other nonmagnetic premium alloys. Drill collars maybe classified according to the shape of their cross-section as round drill collars (i.e., conventional drill collars), square drill collars, or spiral drill collars (i.e., drill collars with spiral grooves). DCs are heavy and stiff steel tubular, and they are used at the bottom of a BHA to provide weight on bit. There are different kinds of DCs available such as flush or spiral DC. In directional drilling, spiral DCs are preferable because the spiral grooves reduce the wall contact area by 40% for a reduction of weight of only 4%. HOME DRILLING PRODUCT LINES DRILL COLLARS COMMAND-SMFI drill collars are thick-walled tubulars machined from solid steel bars and manufactured to specifications to meet and/or exceed API or NS-1 requirements.

(10) 5″OD x 21/4″ID x 19.08'L Slick Drill Collars w/ wrench slots

The collars' length and size affect the type of drillpipe that must be used. Drill-collar selection is usually based on 1) buckling considerations in the lower sections of the drillstring when weight is set on the bit or 2) using a sufficient amount of drill collars to avoid running the drillpipe in compression. The design approaches that. Drill Collar Availablility and Description -- Superior Energy Brands -- HB Rentals International Snubbing Services Stabil Drill Superior Energy - Completion Services Wild Well Control Workstrings International

Drill collars are cylindrical, heavy-duty steel pipes that are an important part of the drill string. The drill string is a series of drilling tools connected to the drill rig and the drill bit, the cutting tool used to penetrate the subsurface rock formations. Drill collars are designed to provide weight and stiffness to the drill string. Home Products Drilling Tools Drill Collars for Drilling Drill collars are thick-walled tubulars that are used at the bottom of the drill string. Sino Mechanical Offers slick drill collars, spiral drill collars, or as per your specific request. Description Overview of Drill Collars

Drill collar

ODs from 2-7/8" to 14" Slick or spiral Mechanical properties guaranteed to 1" below the steel's surface at ambient temperature Enhanced fatigue resistance (threads cold rolled, pin-relief groove and box bore back for API connections) Phosphate-coated threads to prevent galling Slip & elevator recess API stress-relief and bore back Drill Collar Specs, Types & Selection . A Drill Collar (DC) is a heavy, thick-walled steel tube with threaded connections cut (NB not welded) on both ends that we use in oilfield rigs. They are designed to withstand downhole conditions while under compression and tension. While designing BHA, Drilling engineers place DCs above the Drill Bit as DCs are the predominant component of the Drilling BHA.