Begin by dampening the area with water, apply the foam clay, and use your fingers to achieve a smooth finish. For additional refinement, moisten your fingers with water again to further smooth the foam clay. Once the foam clay has dried, it can be sanded. 12K views 4 years ago Cosplayers & Prop Builders, Fine Finish is a quick way to add a sandable or wet-sandable surface to EVA foam for a super smooth finish. This stuff is great if you are.

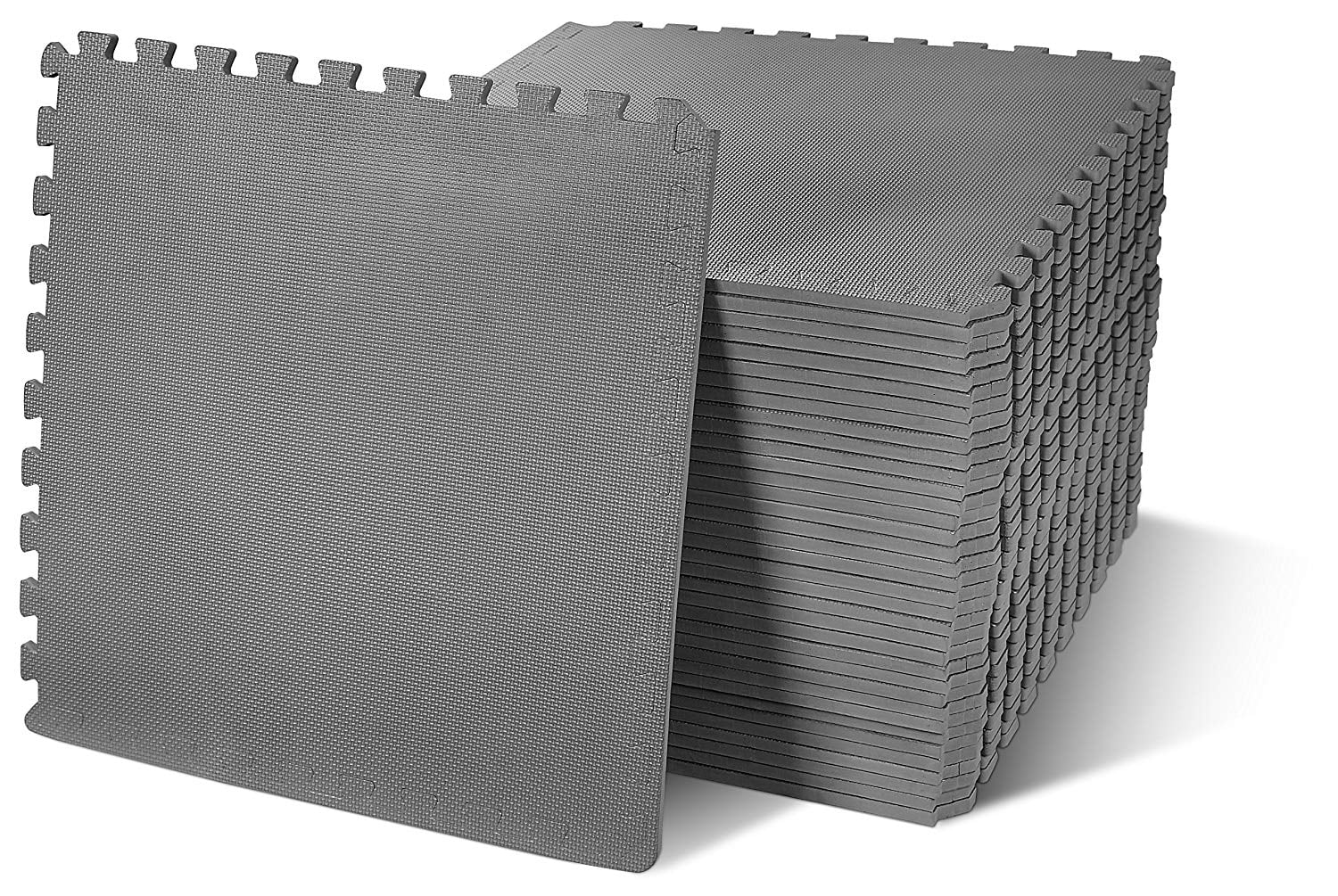

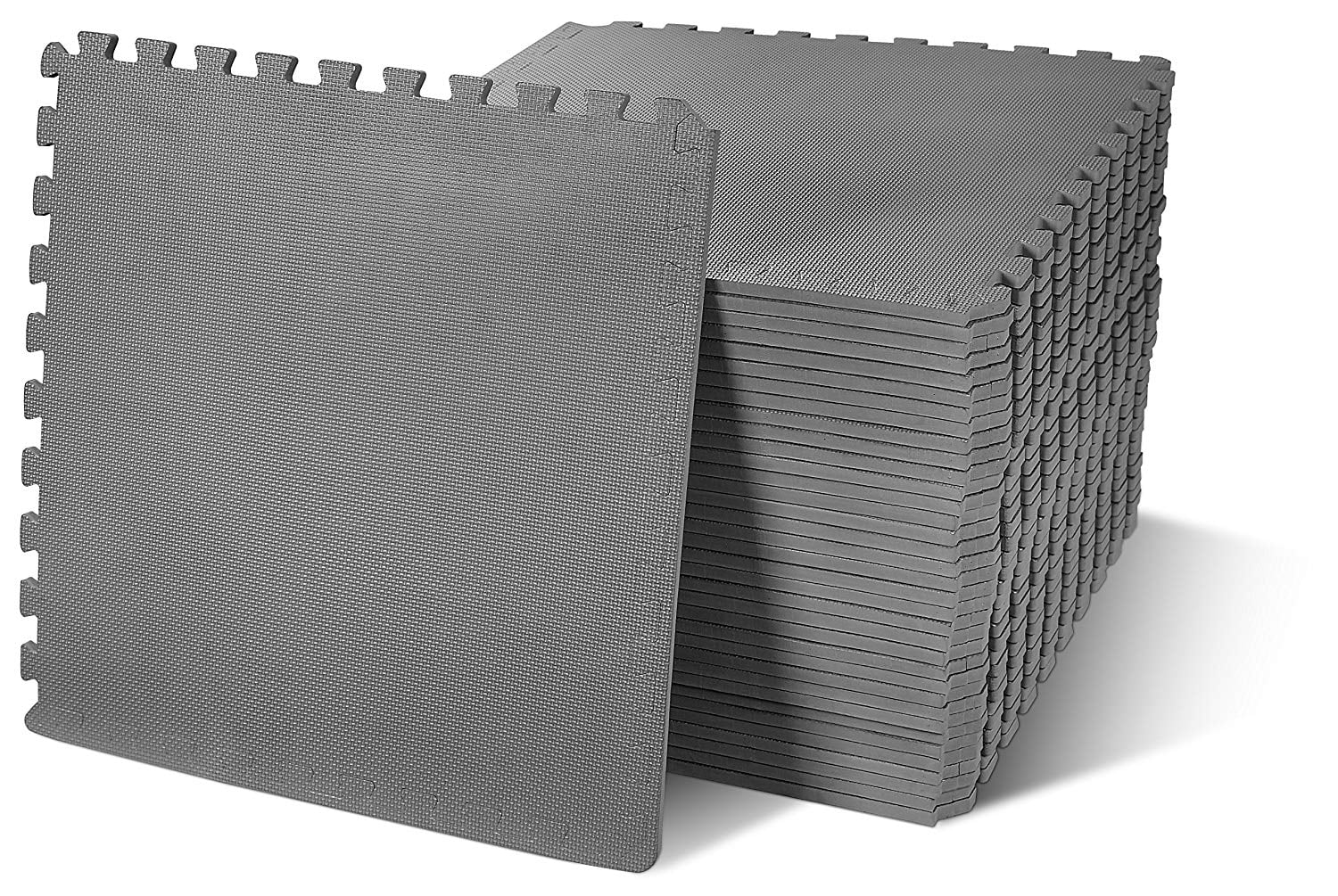

1/2 Inch SUPER EXTRA Thick EVA Foam Mat with Interlocking Tiles 144

Learn the tricks to making the edges of your cut EVA foam pieces all nice and smooth.Buy the Foamsmith book today!http://punishedprops.com/shop/foamsmith-pri. Step 1: Tools and Materials Materials: 4mm and 6mm thick EVA foam sheets Plastidip Weldwood original contact cement or hot glue Tools: X-acto knife and lots of extra blades Heat Gun Dress form or mannequin Glue Gun Saran Wrap One of the most frequent questions we get is how to fix and fill in seams when making props and costumes out of EVA foam. In this video, Bill shows you how t. To achieve smooth and sealed edges on EVA foam, you can use a heat source like a heat gun or a lighter. Gently pass the heat source over the foam's edges, which will cause them to melt and seal. Safety Tips for Foam Cutting. Regardless of the type of foam you're working with, it's essential to prioritize safety.

Custom EVA foam decking in teak and white Smooth Creations Shipwrights

The two easiest methods are using Kwik Seal to fill in gaps and seams and then smoothing the surface of the Kwik Seal with a little water and your finger. The other method is using Foam Clay to fill the gaps and sanding the clay down to make the surface smooth. I will explain each method in further detail in the following. Step 1: What You Will Need - Your Base Shape/ Prop - A Knife, Spoon or Metal Flat Edge - Water - High Grit Sandpaper - A Polyfiller/ Decorator's Caulk Filling Compound - Your Finger Ask Question Step 2: Apply the Filler Using your knife, take a small amount of your filler and apply it to your seem, pushing right in. Go over all the edges and seams to create a smooth prop surface. To shape your EVA foam prop, heat up the plastic then use an object to bend the foam in place until it cools off.. Part 8: Heat shaping and sealing EVA foam. Important: EVA foam releases mildly toxic fumes when heated. Be sure to stay in a well ventilated area. The next step is. EVA foam can be cut by using a box knife, a hobby knife, and even scissors. Make sure that the knife is sharpened regularly because foam dulls knives very quickly. For sharpening knives sandpaper or a whetstone can be used. A rotary tool or sandpaper can be helpful for cleaning up rough cuts.

JFIT High Density Smooth EVA Foam Roller Made in Taiwan

9 Related Topics Cosplay Hobbies 9 comments Best Add a Comment Sumblueguy • 9 mo. ago Heat treat it with a heat gun by using constant back&forth passes. The grit # on your sanding tool may be the issue with why your foam looks rough. The higher number grit you have, the smoother your foam will end up ThrA-X • 8 mo. ago Published on: December 26, 2023 Ever wonder what's behind the cool foam armour and Iron Man costume in cosplay? It's EVA foam! You need pliers and a knife to shape it. Precision cuts and seamless assembly are key for a successful project. But hold on, why journey back in time to the 3D plastic bed's origin story?

Sanding EVA foam can be a tricky business, and especially trying to sand EVA foam to a smooth finish. But, with the right foam, the right tools, and the rig. the lower density/quality of EVA foam, the more difficult it is to get a clean edge. make sure you are using a new/very sharp blade and applyinh enough strength. if you have access to a dremmel/rotary tool, definitely use it to clean up your edges c: a handheld dremmel is about $60-ish depending where you go, whereas a more industrial one will b.

Rapid Fill Smoothing out EVA foam by filling in the surface pores

Get an old shirt, wet it, and press your finger through the shirt and run it along the caulk to smooth it out. 2 Adventurous-Hermit • 3 yr. ago I'm gonna have to try that model magic technique. The problem I've had with caulk is the solvent in it has melted my contact cement and ended up widening the seams. Just mix some ModPodge with a little bit of water and apply it directly to the foam. Once dry, the foam can be painted directly. EVA foam sealed with ModPodge can not be bent without permanently wrinkling. It's just like with white crafts glue. This method of sealing should only be used on props that will not be bent.