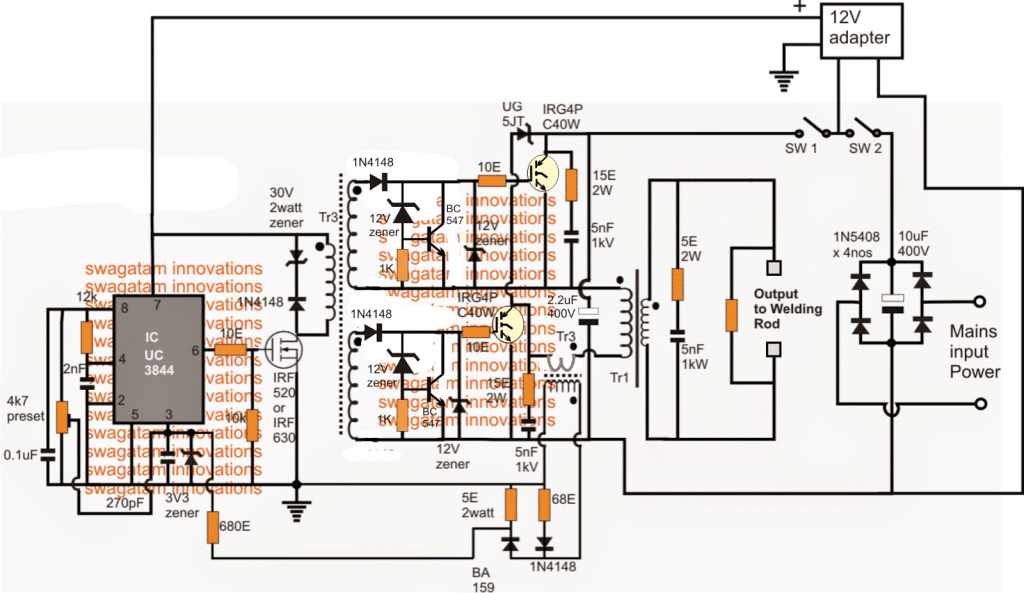

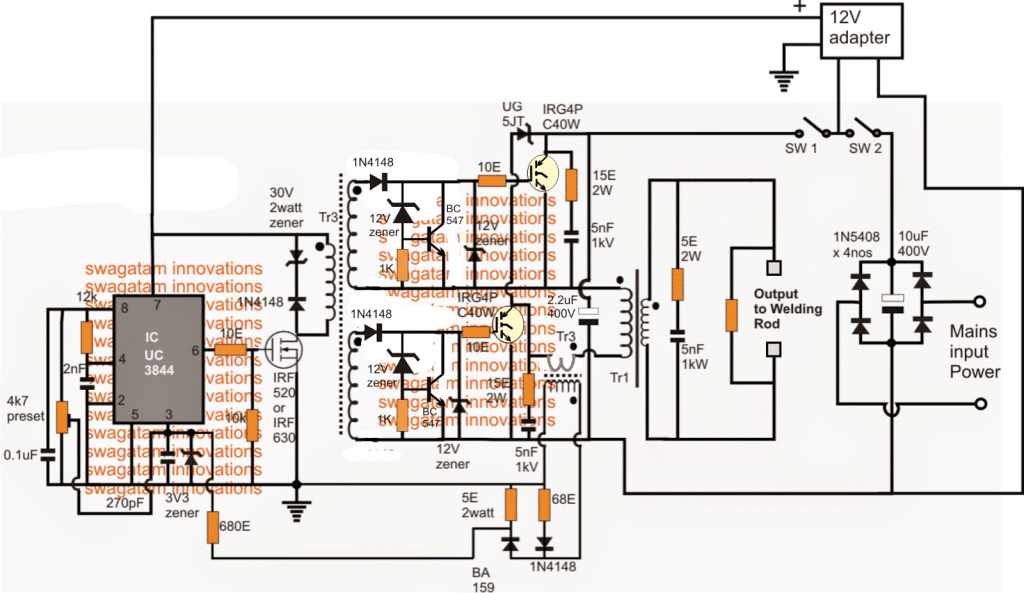

Competitive Pricing on Millions of Electronic Components. Request a Quote Today. Shop Driver Solutions at Digikey. Free Shipping on Orders over $60 AUD. An IGBT (Insulated-Gate Bipolar Transistor) inverter welder is a type of welding machine that uses the IGBT technology for efficient and precise welding. The circuit diagram of an IGBT inverter welder is a crucial aspect to understand how the device functions and how different components contribute to its operation.

Buy Circuit board of ZX7 250 IGBT PCB Single board for

An IGBT (Insulated Gate Bipolar Transistor) welding inverter is a device that converts alternating current (AC) into direct current (DC). This type of inverter is capable of producing high currents and voltages, making it ideal for welding applications. IGBT (Insulated Gate Bipolar Transistor) inverter welding machines are a type of modern machine that makes use of advanced technology to offer high performance and reliability. In this article, we'll look at the IGBT inverter welding machine circuit diagram and explain how it works. Igbt inverter welding machines are powered by an integrated circuit (IC) that converts direct current (DC) into alternating current (AC). This allows for more precise control over the arc, and enables higher quality welds. A circuit diagram is necessary so that the user can understand how the machine works and troubleshoot any problems. But what exactly is an IGBT inverter welder and how does it work? Let's dive into the fascinating world of this powerful tool. IGBT stands for Insulated Gate Bipolar Transistor, a type of power transistor that is used in the construction of the inverter circuit.

Igbt Inverter Welder Schematic Manual

Still the silicon technologies are the rock-solid solution for the today design. The emphasis of this paper is to provide a framework on IGBTs: how to use them in high-power and high-voltage designs. A contextual overview of power silicon technologies and general topologies/applications is provided. Common system requirements for high power. The IGBT, or Insulated Gate Bipolar Transistor, became the most used power electronic component in industrial applications. In the meantime it has become a central component in inverters for all types of electric drives, bat-tery chargers, and solar and wind power plants. But why? What is so special about this component? What is IGBT Inverter Technology? The acronym IGBT stands for "Insulated Gate Bipolar Transistors". These are high-speed switching devices used in all Weldclass Inverter welding machines which facilitate the voltage regulation. Some inverter machines use older MOSFET technology / transistors. IGBT INVERTER WELDER. ARC Series welding system pdf manual download. Also for: Arc120, Arc140, Arc160, Arc180. Sign In Upload.. clip the electrode and then welding can be carried out by short circuit arc starting. For welding parameters, please refer to 6.3. 6.3 Welding parameters table (for reference only) Electrode dia..

IGBT Single Tube Welder ZX7 400 Control Circuit Board/IGBT DC Welder

What Is igbt on welding machines Inverter Welders IGBT Inverter Transistor Tokentools These days IGBT on welding machines reffers to the type of transistors used in the inverter matrix that is at the heart of the inverter welding machines operation. Two additional control signals are required. Extensions possible for higher level Topology (for I-type) 600V devices instead of 1200V increases Efficiency. Composite Losses - Inverter Mode. ETH-Z (IECON 2010) 650 V, VOutput = 325 V , IOutput = 20.5 A. total Composite Losses - Rectifier Mode.

An IGBT inverter welding machine is a type of welding machine that uses an insulated gate bipolar transistor (IGBT) to convert high voltage, low current input into low voltage, high current output suitable for welding. The arc ignition and welding current are easy to control. The controllable silicon rectifier welder is large and cumbersome, making it inconvenient to move, while the IGBT inverter welder has a small transformer due to the high inversion frequency of 20-30kHz, making it lightweight and easy to move.

SMPS Welding Inverter

It is a wiring diagram that can help you understand the functioning of an IGBT inverter welder and its various components, such as the rectifier, the transformer, and the DC/AC power supply. This type of circuit diagram is essential for building and repairing IGBT inverter welders. Table of Contents:. Introduction; UnderstAnding the Function of an InVerter IGBT Welding Machine 2.1 Working of the AC Rectifier Unit 2.2 Testing and Troubleshooting the AC Rectifier Unit; ExpLoring the Output Stage of the Welding Machine 3.1 High Frequency Transformer and Rectifier Unit 3.2 Testing and Troubleshooting the Output Stage; Comparing the Welding Machine with a Simple Mobile.