Industrial Revolution in Western Europe Steam engines promoted automation through the need to control engine speed and power. Pages in category "Industrial automation" The following 103 pages are in this category, out of 103 total. This list may not reflect recent changes . Automation technician PLC technician A Advanced Physical Layer Advanced Plant Management System AS-Interface Automated mining Automatic box-opening technology Automation surprise B Bowl feeder

Industrial Automation Providers the Top 10 Robot Makers for Manufacturing

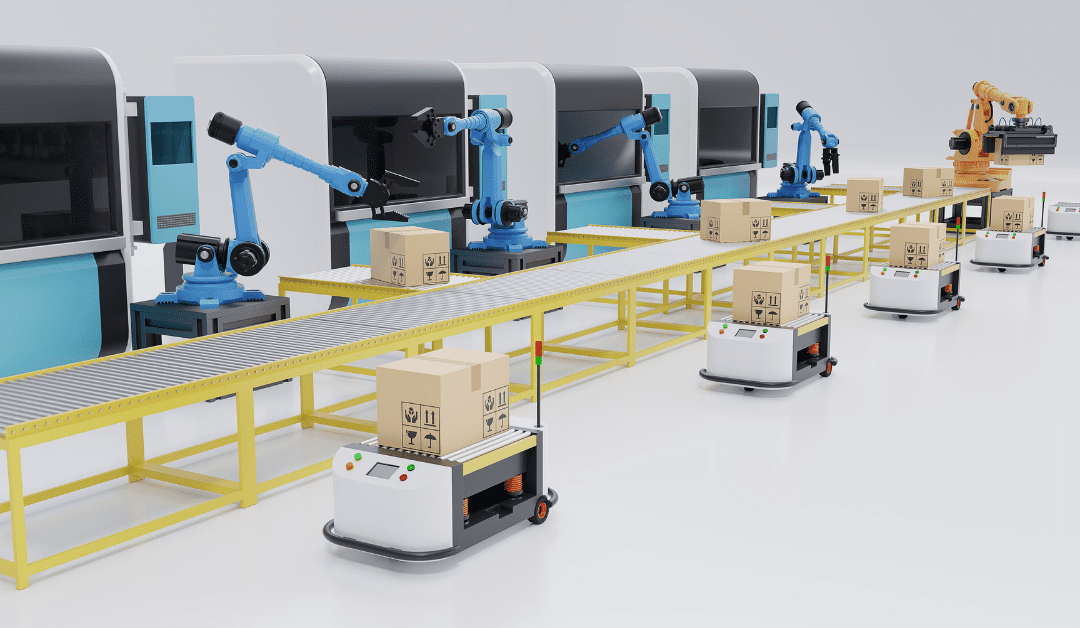

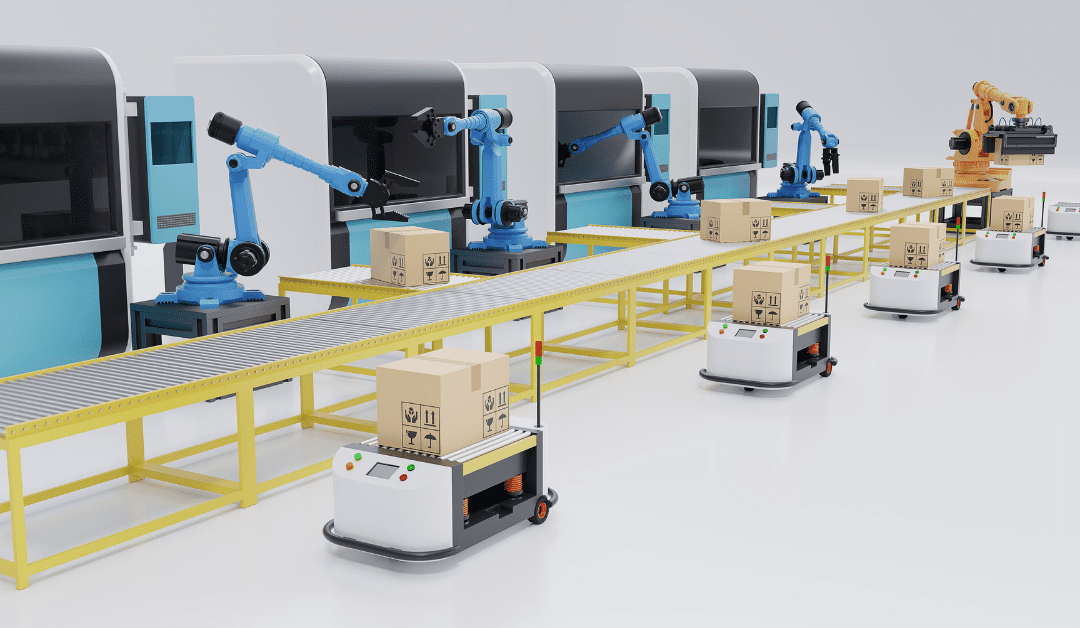

(January 2021) This glossary of industrial automation is a list of definitions of terms and illustrations related specifically to the field of industrial automation. For a more general view on electric engineering, see Glossary of electrical and electronics engineering. For terms related to engineering in general, see Glossary of engineering . Industrial automation is a complex, dynamically evolving and utterly fascinating technology field. This guide covers the basics of industrial automation, including its main principles and concepts, technological solutions powering modern-day automation and their applications in the industrial environments. Intro Industrial automation uses information technologies and control systems like robotics and sensors to carry out industrial tasks previously performed by human workers. Industrial automation can reduce injuries associated with repetitive motion and lifting objects to create a safer work environment. This initial benefit can make a worker's day-to-day better while freeing them for more complex tasks. Downtime, performance problems, and bottlenecks all slow down production.

What is Factory Automation / Industrial Automation? ECUBERS

Industrial automation is the use of control systems, such as computers or robots, and information technologies for handling different processes and machineries in an industry to replace a human being. It is the second step beyond mechanization in the scope of industrialization. Increase Quality and Flexibility in Your Manufacturing Process Autonomy as a service is the offering of automated, fully unmanned systems by a service provider. The offering enables companies with little experience in automation to utilize automated systems they would be otherwise unable to manage. Under autonomy as a service, maintenance remains the responsibility of the automation provider. Industrial automation is the use of technologies such as computer software and robotics to control machinery and processes which replace human beings in performing specific functions. The functions are primarily centered on manufacturing, quality control and material handling processes. Industrial Automation is a process of operating machines and other industrial equipment with the help of digital logical programming and reducing human intervention in decision making and manual command process with the help of mechanized equipment.

Industrial Automation KMakin Technologies Inc

An industrial control system ( ICS) is an electronic control system and associated instrumentation used for industrial process control. Control systems can range in size from a few modular panel-mounted controllers to large interconnected and interactive distributed control systems (DCSs) with many thousands of field connections. Before delving further into the futuristic implications of industrial automation, let us first understand what industrial automation is. After mechanization in the first industrial revolution and assembly lines in the second industrial revolution, manufacturing had achieved abilities to scale and grow. But post world-war, booms in economies.

Simply put, industrial automation is the process of integrating computerized machinery, control systems, or other information technologies into your organization to replace human operations. Industrial automation uses both hardware and software to streamline a variety of physical processes. Industrial automation is the use of computer and machinery aided systems to operate the various industrial operations in a well-controlled manner. Depends on the operations involved, the industrial automation systems are majorly classified into two types, namely process plant automation and manufacturing automation. Process Plant Automation

Industrial Automation Automated Industrial Technologies Robustel

Industrial automation uses control systems like robots, computers, or information technologies to handle industrial machinery as a replacement for human beings. The difference is in machinery control. Automation has used power from electricity, water, or other sources to run machines since the beginning of the industrial revolution. Digitalization requires data aggregation, standardization, and contextualization at scale. I believe the missing link to industrial transformation is a codeless solution that can aggregate, standardize, and contextualize industrial data from sensors, controls, and other industrial automation assets and systems for use by business users throughout the company and its supply chain.