Home Belt-Driven 4000 Series ProMetrix is the perfect match for custom applications, such as drilling, boring, milling, turning, grinding, assembly, winding or balancing applications that process metal, composites, glass, wood, and other processing equipment. Spindle Features 15 Standard Sizes 5 Housing Styles All belt driven spindles operate at a fixed speed and incorporate a timing belt for positive power transmission. Standard motors are 230/460 volt 3-phase 60-Hz with other voltage options, gear motors, and inverter rated motors also available.

Turning BeltDrive Spindle ROYAL High Precision Spindles

Belt Drive: Setco's belt-driven spindles are a popular choice and make up a large percentage of shipped spindles. They are available in block, flanged cartridge, and cartridge models. Belt Drive Spindles Here are five advantages to a belt-driven spindle from Setco. Reduced noise: Belt drive spindles tend to generate less noise compared to other types of spindles, which can help create a more comfortable working environment. A multitude of options: Belt-driven spindles can be created to meet a broad set of characteristics with significant range in available spindle power, speed and torque, which are often based on the motor that your spindle is supporting. CNC specialty spindle options are available in many belt-driven flavors. turning spindle HDT-170. high-speed high-torque belt-driven. Rotational speed: 50 rpm - 5,000 rpm. Diameter: 170 mm. HDT series product line is HARDY new developed spindles for turning applications. The housing selections are 150, 170 and 200mm with maximum RPM up to 6000. HDT spindle is the perfect solution for variety.

Belt Drive Spindle Yamaris Machinery Pte. Ltd. Singapore

8. Apply anti-seize to spindle bolts and tighten them. Then remove the threaded rods. 9. The spindle replacement kit includes a silicon seal. After tightening the spindle bolts, apply silicon seal on the spindle bolts. 10. Screw the belt tensioner tool in the designated hole. Tighten until the tool touches the mounting plate. [Figure 19]. 11. Dynamic balancing will be preformed on spindle equal to and above the speeds given in the table. The balancing grade is ISO G2.5 for the operating speed of the spindle. Spindles that are not belt driven will be balanced using a half drive key. Spindles that are belt driven will be balanced with the pulley/bushing mounted on the shaft and in. GD.Marsh's RF-45 Belt Drive Some pix and comments from his CNCZone thread: Exploded view of the mill head. This conversion involves the part with the red arrow… The sleeve contains the splines that engage the spindle. A gear had to be turned off the original… Components… Bearings will be used to support the sleeve… The spindle must be able to hold the tool-holder with uniform contact on the mating surfaces. Rust spots will inhibit uniform contact allowing the tool to rock or move as the machine is running causing accelerated taper wear. Use only tool-holders that meet JIS B 6339 standards. Poorly manufactured tool-holders can reduce tool-to-spindle.

Bt30 12000rpm Cnc Belt Drive Spindle Buy Belt Drive Spindle,Bt30 12000rpm 90mm Spindle,Milling

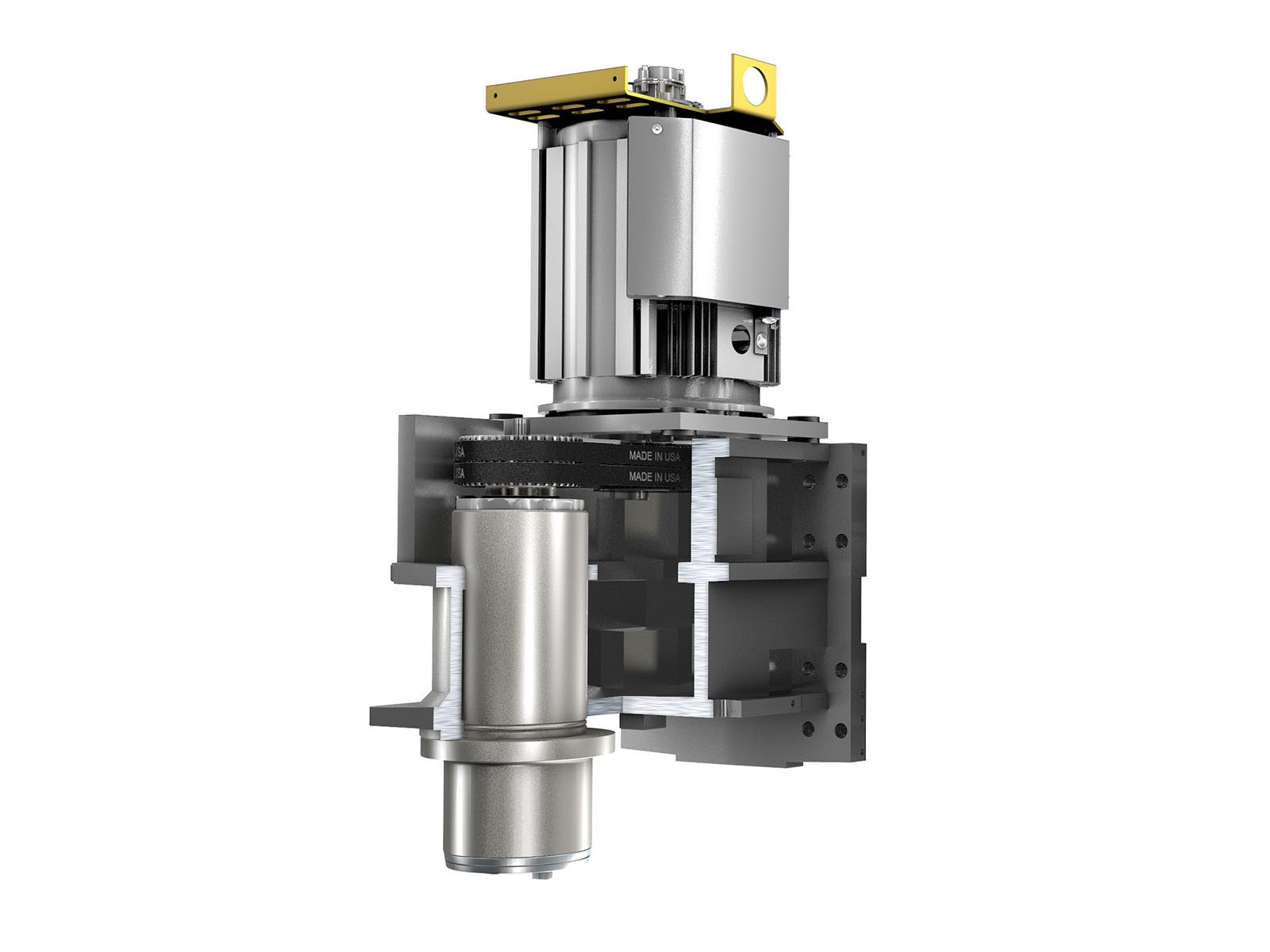

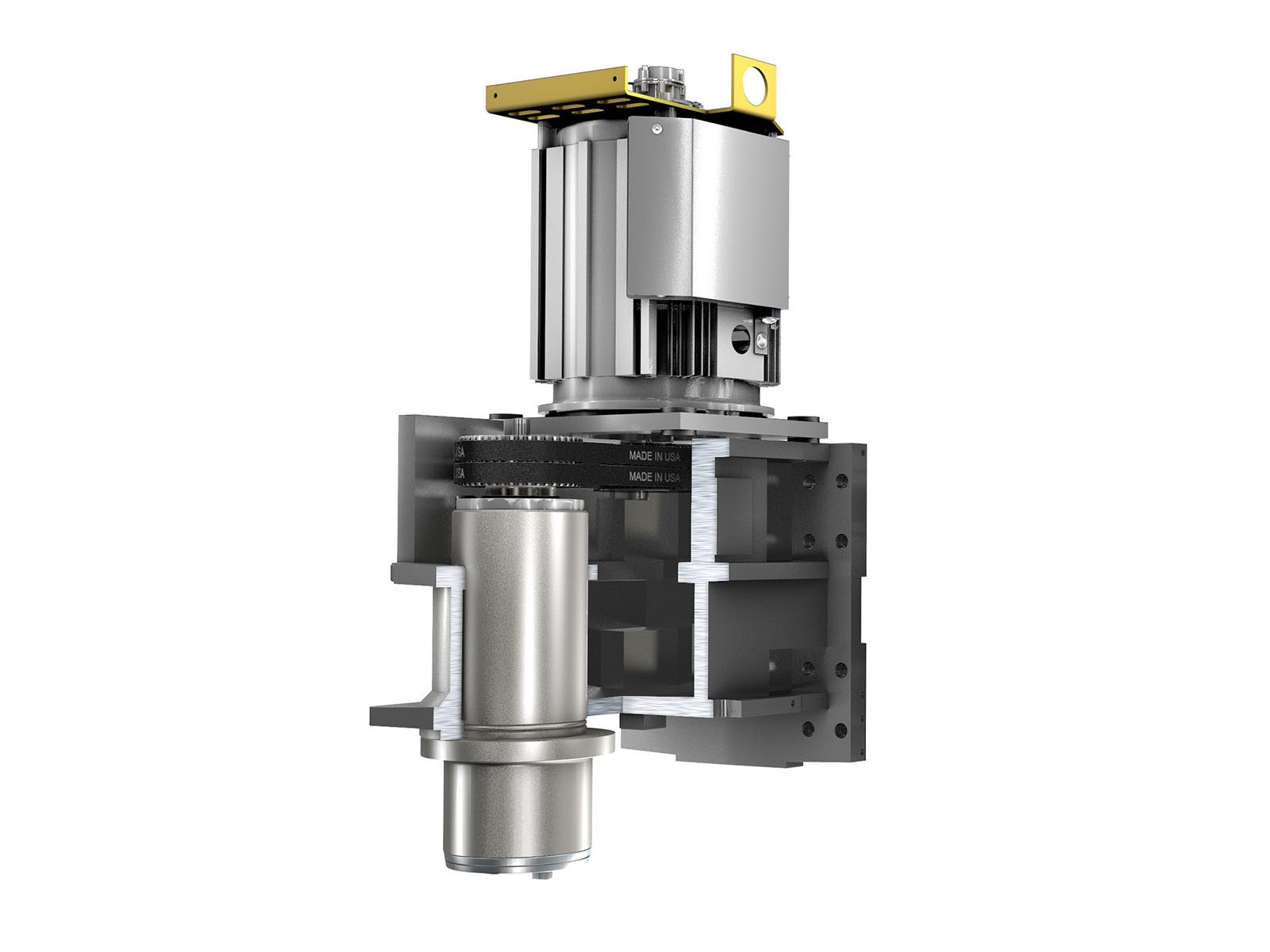

BELT-DRIVE SPINDLE OUTPUT. Top High Torque Gear Spindle 2-speed super heavy-duty gear box.( Gear spindle are all equipped with box way Z-axis. ) Floating type hydraulic tool release device eliminates pressure on the spindle bearing when releasing a tool. 8,000 rpm high torque spindle ( BT40 ) is equipped with powerful 11 kW motor delivers. Belt Driven Block Spindles Our spindle manufacturer offers design, build and manufacture of block spindles used in the automotive, aerospace, military, tooling, wood, plastic, stone, marble and glass industries. Enter the dimensions of your block spindle in the Request a Quote form. We will respond with a quotation.

A belt drive spindle is a type of spindle that uses a belt and pulley system to transmit power from the motor to the spindle shaft. The spindle shaft is housed in a block housing, which provides support and stability during machining operations. This 15,000-rpm belt-drive spindle provides high rpm at a very affordable price. Take advantage of the increased rpm to greatly increase spindle speed, and therefore feedrates, on soft materials and with small cutting tools. This system features a Haas-built cartridge spindle that is driven by the motor via belt.

Spindles

Belt Drive This system features a Haas-built cartridge spindle that is driven by the motor via belt. This provides a good combination of torque and rpm for a wide selection of machining operations. It is a great overall value. Inline Drive Home Products Motorized Spindle Milling Spindle Belt Drive Spindle BT40, Ø150 B elt Drive Spindle BT40, Ø150. High Precision, High Rigidity, High Speed, Low Vibration, High Reliability.. Belt Drive: Clamping Force: 1000±100 kgf: Clamping Form: BT40 4 Petal Clamp Pull claw: Taper Runout: 0.002 mm: Root of Test Bar Runout: 0.003 mm: 300 mm.