Fast and Free Shipping On Many Items You Love On eBay. Looking For Fanuc? We Have Almost Everything On eBay. Fanuc G71 Turning Cycle G71 turning cycle is used for rough-material removal from a cnc lathe component. G71 turning cycle makes large diameter cutting easy. Cutting can be done in simple straight line or a complex contour can also be machined very easily. Through G71 turning cycle parameters cnc machinists can control Depth of cut. Retract height.

CNC TORNA FANUC G71 VE G70 ÇEVRİMİ ÖRNEK PARÇA YouTube

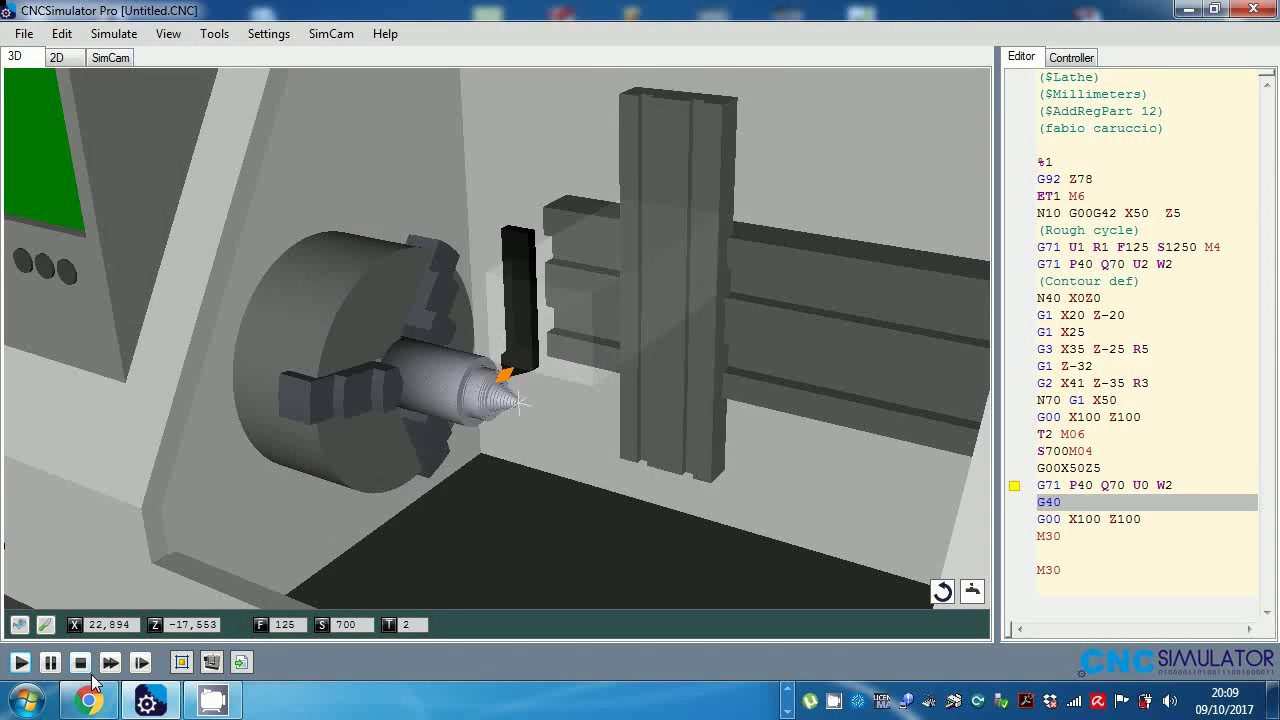

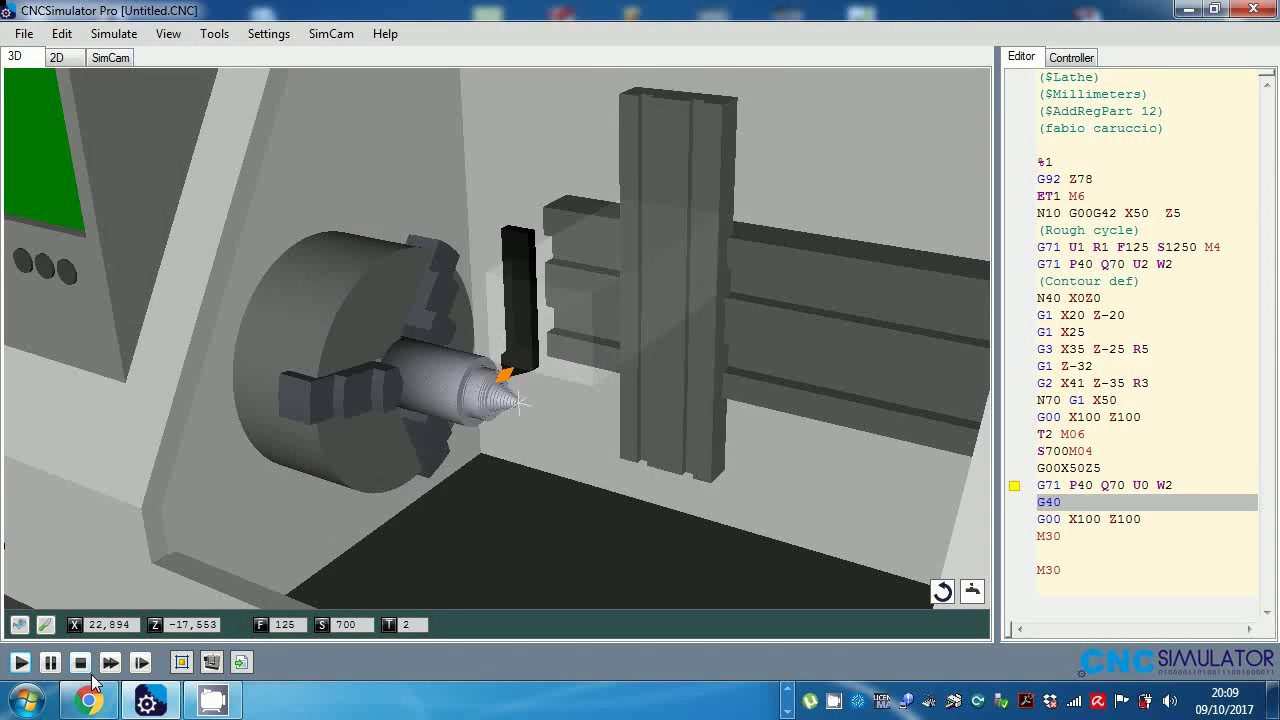

G71 is our G-Code that lets the controls know that we wish to use a roughing cycle and that the following information applies to that. The U on the first line of code is the depth of cut of each roughing pass. The R refers to how far the tool will retract from the part in X when returning in rapid to the start of the cycle. Here is a very simple profile: A simple profile consisting of 3 G01 segments with a G00 to the starting point… This profile consists of 3 G01 line segments with a G00 rapid move to the starting point of the profile. The code associated with the profile is trivial: N1 G0 X1.6 N2 G1 Z-4.0 N3 X2.5 Z-5.0 N4 G1 X4 Fanuc G71 for Boring Opertaion This programming example also illustrate how G71 turning cycle can be used for internal machining (boring operation). So if you want to remove extra stock from inside of a component, you can use Fanuc G71 turning cycle for internal stock removal as well. Fanuc Programming Example Fanuc Canned Cycle Example This video explains the use of G71 and G70, roughing and finishing cycles on a Fanuc or Haas control. It demontrates the one line G71 as used on the Haas CNC.

G71 FANUC ROUGH CYCLE YouTube

Learn how to use the G71 canned cycle for pocket roughing on a CNC lathe with TYPE II Fanuc controls.O0001 (TURNING POCKETS)G0G28U0.T0101G97S1000M3G0 G54 Z.1X. Diameter value. F = Feed. G71 roughing cycle on the lathe can be called "auto turning cycle". It is not a repeating cycle in the way that peck drilling is. G71 needs some parameters so it does not cut into the true profile of the part. D is amount for each pass. It is the tool movement for a cut, taper, or angle. G71 is sometimes known as a canned cycle when in fact it is a multi repetitive cycle. The G70 cycle goes with it and can pick up the same lines to finish. The N numbers are important as the cycle uses these as the points of reference to jump to. G71 cycle interprets the shape between these two N numbers and then breaks up the shape for roughing. If the control is a Fanuc control, TNR Comp will be ignored completely in the G71 Cycle. Even if it were to work in the G71 Cycle, you have cancelled it before executing the G70 Block and therefore, the part profile shape will be finished without TNR Comp and the part made into scrap.

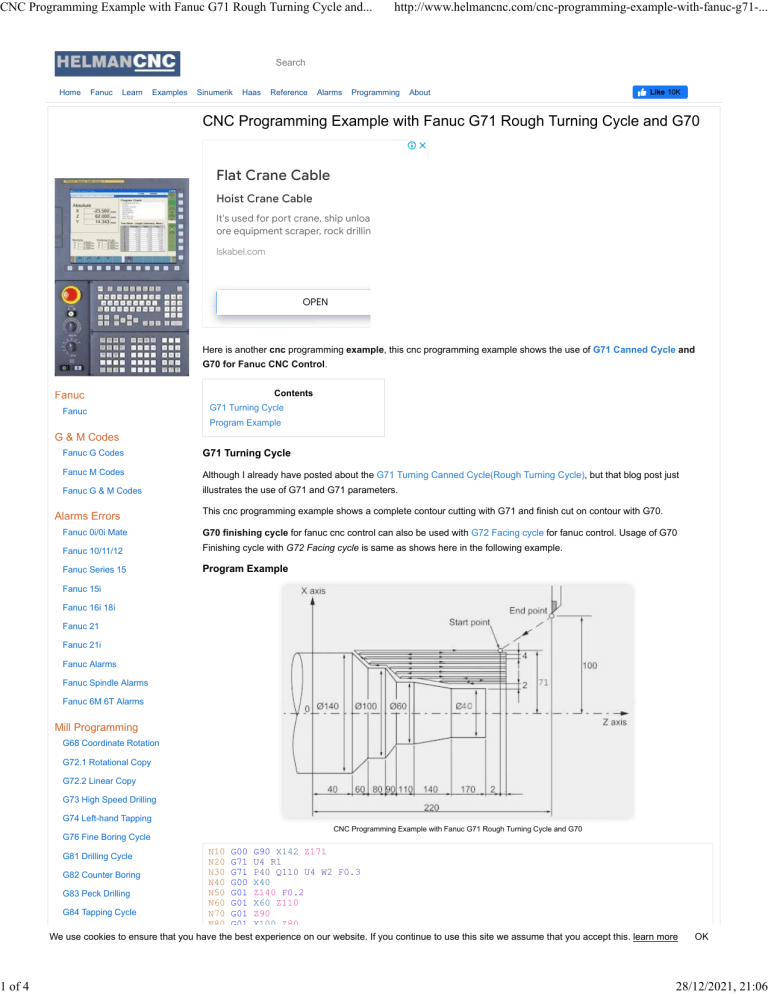

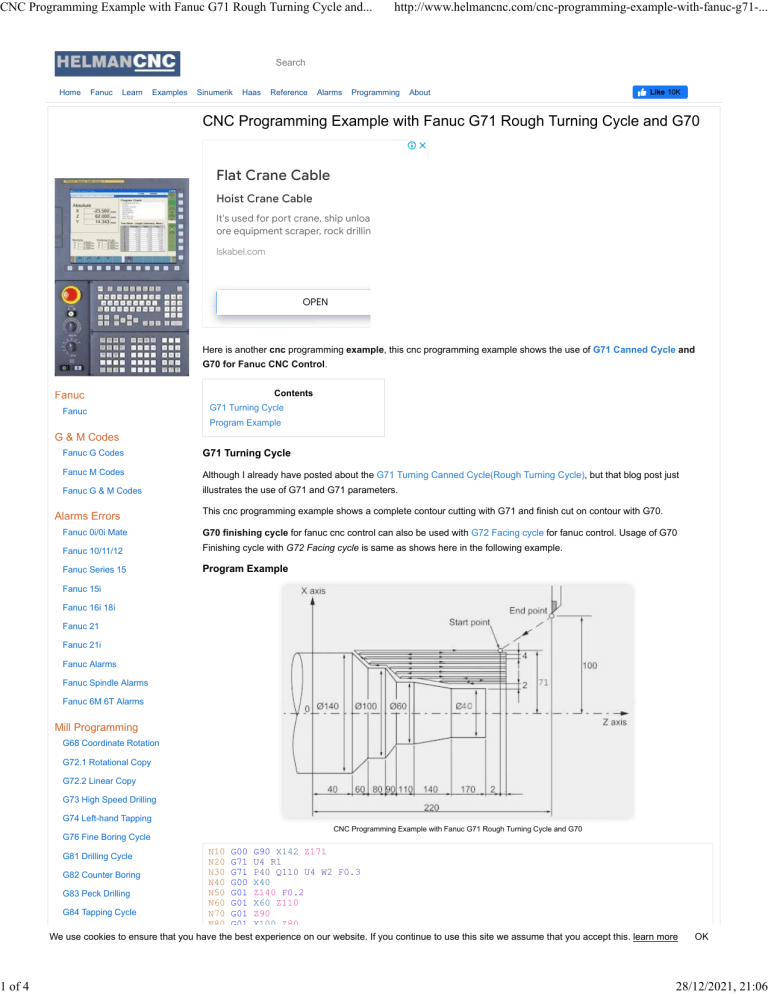

CNC Programming Example with Fanuc G71 Rough Turning Cycle and G70 Helman CNC

The G71 rough turning cycle available on many controls is really handy. You specify a profile in g-code and the G71 cycle deals with roughing it out.. I used Fanuc syntax there, but remember, your control may use a different syntax. This approach is simple, but won't run as fast as a real G71 because we use the same profile for. Control is fanuc, and we're talking about cycle G71, and both (Type I/Type II) options installed on machine. See attachment for profile (Only doing the white profile, ignore the two red lines) And the profile starts from higher diameter ofc. My claim was that if you dont give Z-movement on first line after the cycle, it would do the profile.

What is a "Type II" G71 Cycle? As was mentioned in the article on G71 Type I, the Type II cycle is suitable for profiles with pockets. Profiles that have no pockets are called "Monotonic", a term you may have seen either in your controller documentation or perhaps as an alarm on your code if you've been playing with G71. Fanuc lathe programming example which uses Fanuc canned cycle G71 Turning Cycle G70 Finish Cycle G74 Peck Drilling Cycle This Fanuc lathe programming example illustrates who to use G71 Turning cycle, G70 Finish cycle, G74 Peck drilling cycle for ID machining (Inside machining, boring operations) Contents Fanuc Lathe Programming Example

TURNING POCKETS USING A G71 CANNED CYCLE YouTube

G71 TYPE II CANNED CYCLE, I'M CONFUSED! Hi All, I have a couple of lathes with fanuc controls. One is a 10TF the other is a 16TT. I'm machining rollers with basically a V groove in the OD and a rad in the bottom of the groove. (prog below) Both machines run the type 2 canned cycle. The parts machine fine on the 10TF. FANUC STOCK REMOVAL ROUGH TURNING CYCLE G71 II EXAMPLE STOCK REMOVAL ROUGH TURNING CYCLE G71, CNC CYCLE G71 (turning cycle) SINUMERIC CNC PROGRAMMING FOR COMBINE STOCK REMOVAL CYCLE & THREADING (COMBINE CYCLE 95 & 97 ) SIEMENS COMBINE CYCLE CNC PROGRAM IN HINDI , FANUC COMBINE CANNED CYCLE G70 G71 G72 FOR INTERNAL LATHE OPERATION ,Peck drilling cycle for turning (G74 cycle) ,CNC Fanuc G73.