To do this, you'll want to make a cast mould of your foot; that way, the shoes you'll be making will be custom-fitted for you personally. Get a box filled with an alginate jelly and place your foot in, ideally up to the ankle. Let your foot rest for 20 minutes while the jelly solidifies, then slowly remove your foot. In shoe making you can use different materials for soles. The easiest way is, to use ready-made rubber soles but if you want to learn how to make shoes with natural materials, you always need to use the vegetable tanned leather. For women shoes we use the vegetable tanned leather with a thickness of 2-3.5 mm, for men shoes 4-5 mm.

New Video How to make simple shoes using your feet as lasts Simple Shoemaking

This is a new take on making shoes without using lasts - as you will see while watching this video, your foot becomes part of an ensemble of materials that c. Have you ever wanted to know how to make shoes? We spend most of our life wearing sneakers so in this video I take you inside of a factory that makes thousan. I Can Make Shoes is the worlds leading independent shoemaking school. Learn to make your own shoes from home following the I Can Make Shoes shoemaking videos and tutorials. #shoemaking #icanmakeshoes #howtomakeshoes Making shoes is such a fun and rewarding DIY project, whether you're looking to create a unique pair of shoes for.

Make Your Own Shoes at Home! 33 Steps (with Pictures) Instructables

Step 28: Sew Your Upper to Your Sole. Put your insole and last into your upper (with its laces tied). Because your patterns continued onto the bottom of your last, you should have extra fabric that hangs down past the sole. Hold the fabric tightly against the ring of sole you glued on in the previous step. Step 2: Prepare the Materials. To create high-quality shoes, we need to ensure we have the right materials. This includes selecting the appropriate leather or fabric, lining, insoles, and outsoles. Each material should be chosen carefully, considering factors like durability, comfort, and aesthetics. Investing in top-notch materials is. With the sole in place, start stitching and gluing your other pieces in place. Each shoe design will be slightly different, and it is up to the shoes maker to decide how the stitches can be applied. Make sure that your pieces connect properly together and make a complete shoe body. Otherwise, you might have to make new pieces to fill in the gaps. Shoemaking Steps. Let's talk about the steps in shoemaking. The basic idea is to sew the upper in a shape that resembles a sock, then stretch the upper over a foot-shaped form called a last. Once the upper is stretched over the last, the shoe bottom is glued, stitched, or nailed to the shoe upper. When the last is removed the shoe is complete.

Shoe Making Tutorial Cosplay Amino

Once wrapped around the last, the uppers are then attached to the insole board. 3. Insoles. Depending on the type of shoe you're making, you may have flat insole, a mid-height insole, or a high-heel insole. It doesn't matter what kind of insole board you have, as long as it matches the pitch of your last. Polish leather shoes with a high-quality polish, and apply it evenly with a soft cloth. Allow the polish to dry completely before buffing the shoes to a shine. Store your shoes in a cool, dry place away from direct sunlight. Avoid storing them in plastic bags, as this can cause the leather to dry out and crack.

Here's a concise breakdown of the shoe-making process: First, we design and apply a chosen shoe design onto the appropriate shoe last, creating an initial mock up. From this, we craft a foundational shoe template. This template helps us shape the patterns for both the shoe upper and lining. How to fix loose sides of your shoes upper. Join our online shoemaking courses and access over 500 hours of step-by-step classes. Get dedicated support, learn from beginner to advanced levels, and master everything from crafting sneakers to creating welted shoes. Your pathway to professional shoemaking starts here.

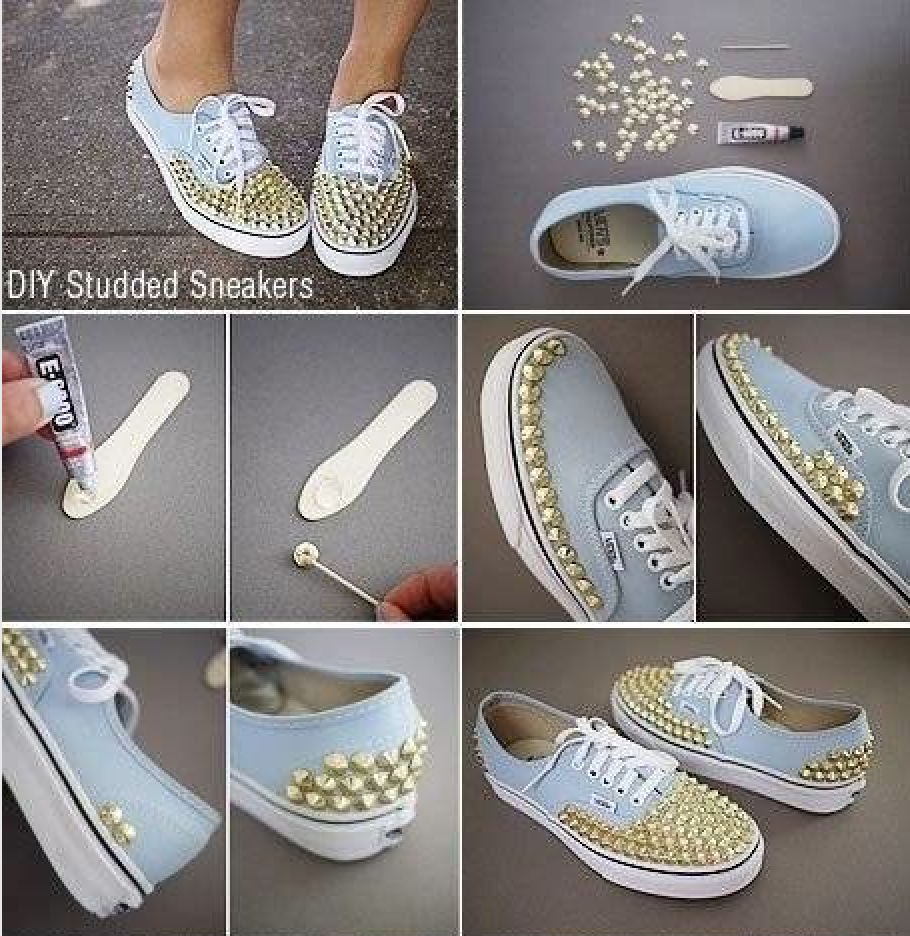

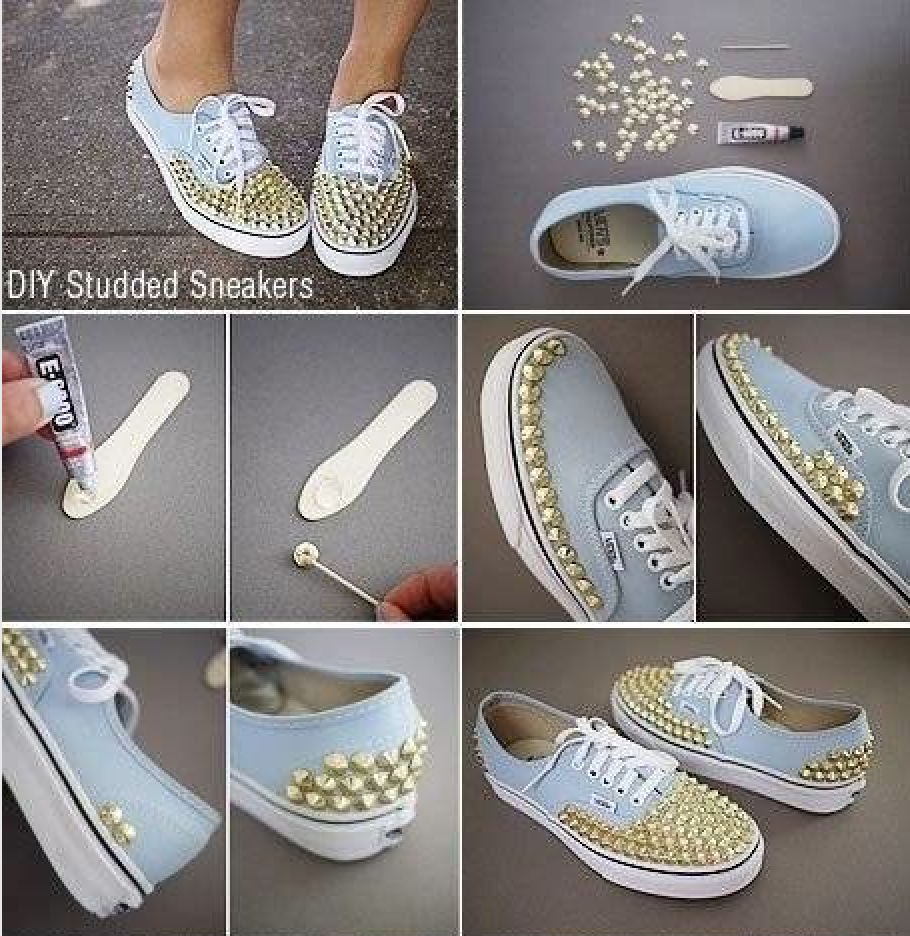

12 DIY Footwear Projects Top Dreamer

Step 3: Stamping and Sewing. Partly due to the sheer number of pieces used to make one shoe, constructing footwear is a true craft. The pieces needed to make the shoe are cut from high quality leather then next in the shoes manufacturing process comes stamping. Now the shoe is referred to as a shaft and the pieces of leather that make it are. Janne Melkersson of Melker Shoes. The cost is 27000 SEK ($3000) for one week and 50000 SEK ($6000) for two weeks. It might sound costly and short, but you get one on one tutoring, accommodation, food and more. You also make 2 Bespoke Handmade Shoes and keep them, as well as copy all of the patterns that Janne has.