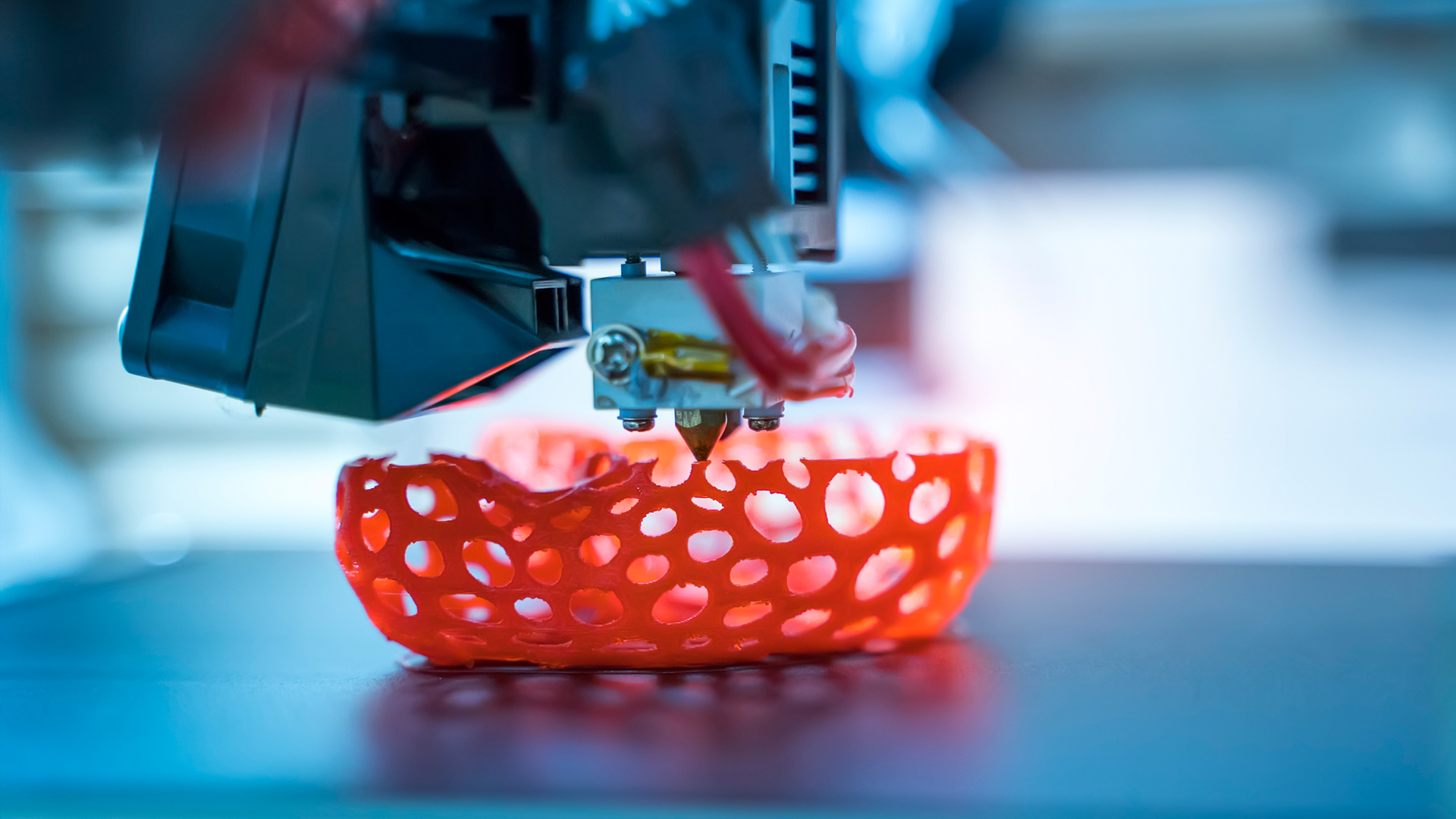

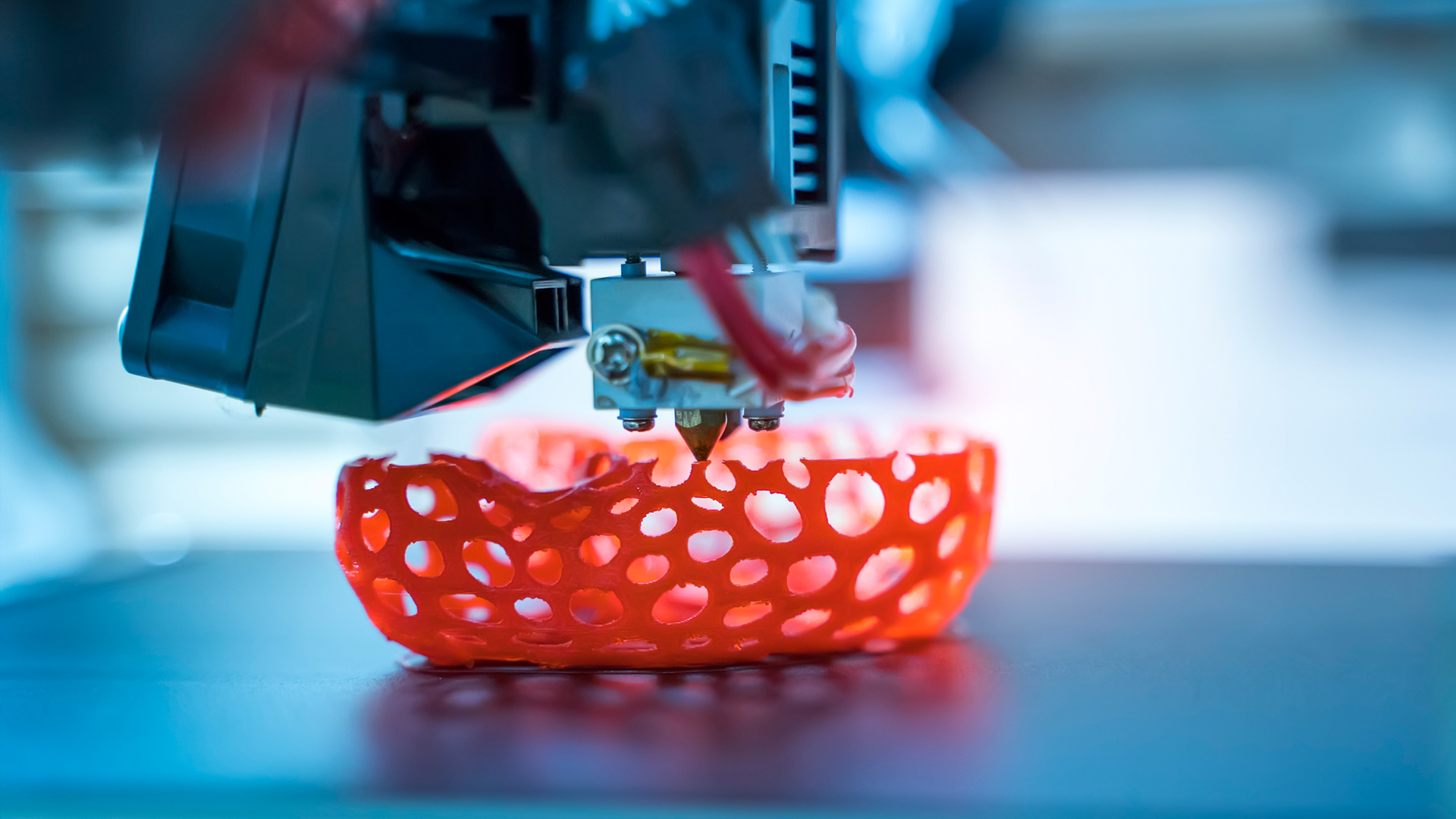

Currently, 3D bioprinting technologies have emerged as a powerful tool to build bioengineered skeletal muscle constructs 2, 25, 26, 27, because these technologies can generate structurally. Here, we applied 3D bioprinting strategy to fabricate an implantable, bioengineered skeletal muscle tissue composed of human primary muscle progenitor cells (hMPCs). The bioprinted skeletal.

ArtStation Anatomically correct muscular male body Low and High Poly Lowpoly 3D model Resources

The team used digital light processing, a 3D-printing technique, to fabricate the muscle layer by layer and embed light-emitting diodes (LEDs). The material bends when part of it is heated, and. Technological advances in three-dimensional (3D) printing and its biomedical adaptation, 3D bioprinting, have the potential to provide viable, autologous tissue-like constructs that can be used to repair musculoskeletal defects. The monolithic design of the GRACEs enables the direct 3D-printing of artificial muscles and functional pneumatic devices in one step. The GRACEs, therefore, enable the realization of complex actuated structures with smooth movements that mimic those of animals and humans. Moreover, the GRACEs' development process—consisting of modeling. Scientists have invented a 3D printed synthetic muscle that can lift up to 1000 times its own weight. In a paper published earlier this week, Aslan Miriyev, Kenneth Stack and Hod Lipson from.

Designing 3D printed artificial muscles from motor proteins

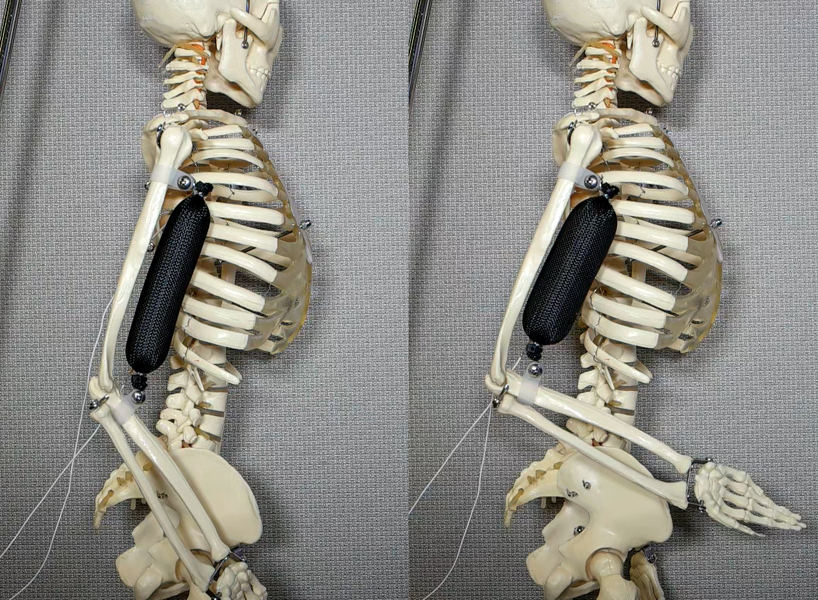

1. Introduction Skeletal muscles represent ~45% of the human body weight with over 600 different skeletal muscles involved in skeletal support, stability, locomotion and dynamic events, including regulation of metabolism. A well-organized 3D skeletal muscle tissue in a dimension of 15 × 6 × 4 mm using human skeletal muscle cells was printed. dECM sponge and bulk dECM hydrogel with the same dimension were prepared in parallel as a control. In vitro study with pimonidazole showed that significant hypoxia occurred in bulk dECM hydrogel. Open access Published: 14 October 2021 Matrigel 3D bioprinting of contractile human skeletal muscle models recapitulating exercise and pharmacological responses Angela Alave Reyes-Furrer, Sonia. Abstract Volumetric muscle loss (VML) is an irrecoverable injury associated with muscle loss greater than 20%. Although hydrogel-based 3D engineered muscles and the decellularized extracellular matrix (dECM) have been considered for VML treatment, they have shown limited efficacy.

3D printed synthetic muscle is up to three times stronger than human tissue

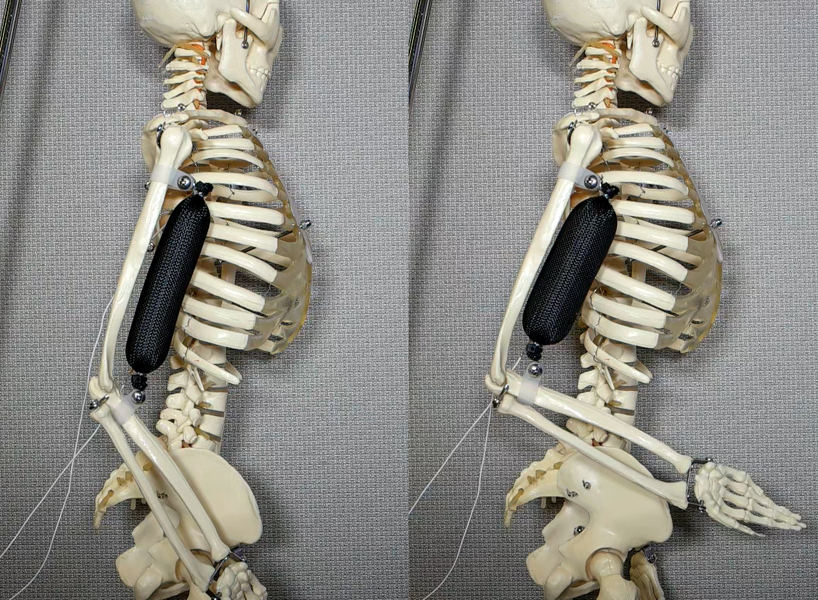

Using a standard filament 3D printer, artificial robot muscles can be directly printed. These air powered muscles can be used in all kinds of robots or powered prostheses. Intro pic shows a six muscle flower robot activated. Such a simple robot could be used to indicate air pressure, temperature or as a protective enclosure that opens up. The applications of 3D printing technology coupled with micro-fluidics to generate 3D in vitro muscle models, as demonstrated by previously mentioned examples, possess significant potential for the future of muscle development studies, disease modeling, and drug screening compared to 2D culture models.

Researchers at the Terasaki Institute in Los Angeles have developed a new method to create 3D printed muscle constructs with enhanced muscle cell alignment and maturation. The technique involves. 3D-printed heart muscle beating through fiber-infused ink Over the last decade, advances in 3D printing have unlocked new possibilities for bioengineers to build heart tissues and structures.

.jpg)

3D Bioprinted Muscles

The fiber-infused gel (FIG) ink allows the 3D-printed heart muscle cells to align and beat in coordination like a human heart chamber. The immediate goal of the researchers is to discover new. 3D-printed muscles could be coming to a hospital near you But not just to get jacked. by Sarah Wells Feb. 28, 2020 Shutterstock Muscle damage, like tearing your ACL, can be traumatic and lead.

.jpg)