What Is the Machine Base Plate Grouting Procedure? Properly grouting a sole plate involves the following steps: Preparing the surface of the concrete and the sole plates. Before installation of the grout, the surface of the concrete and the plate must be adequately prepared. This method statement describes the step by step procedure for grouting of machine bases and base plates using the SikaGrout range of ready to use mortar products and shall be read in conjunction with the relevant product data sheet and safety data sheet.

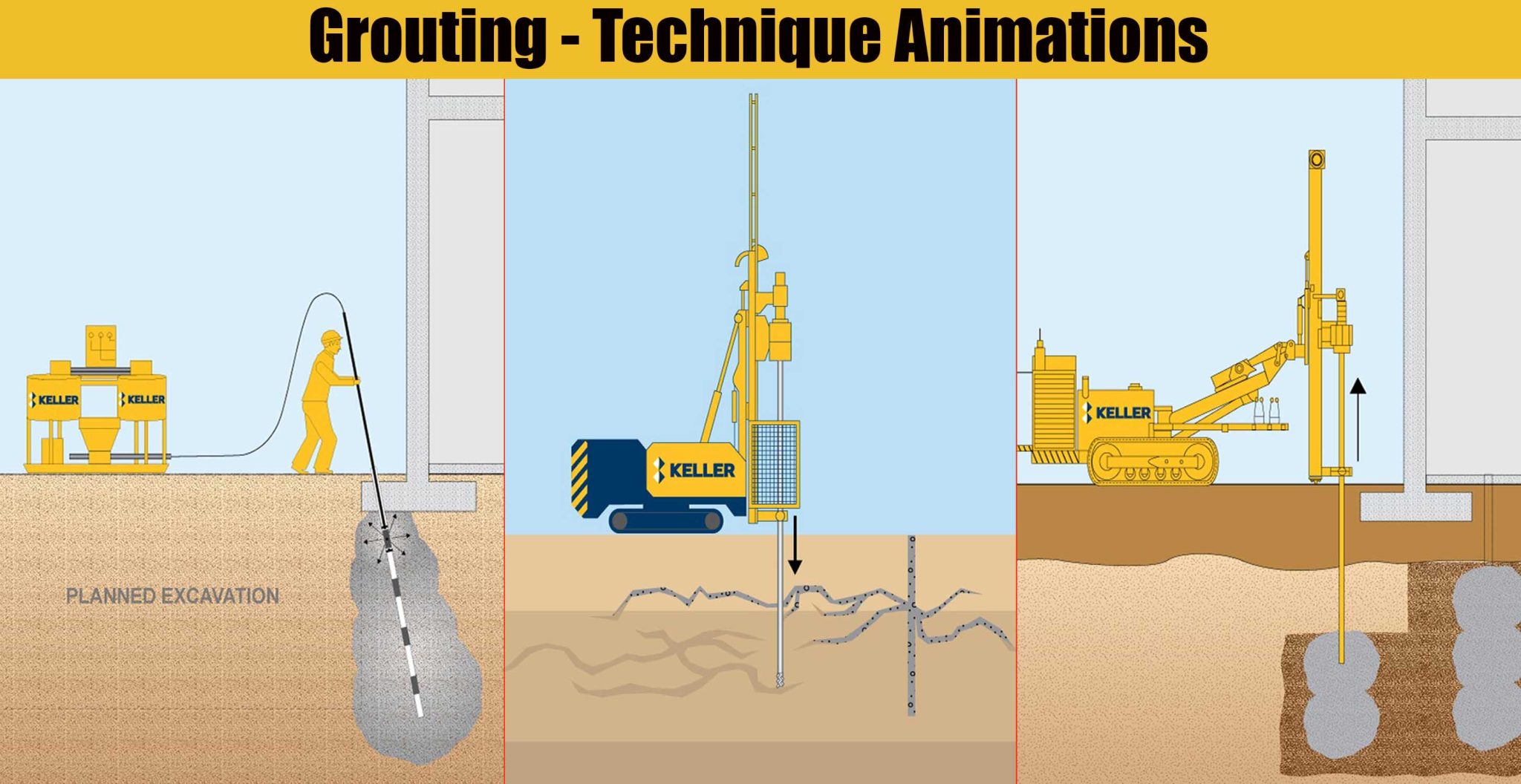

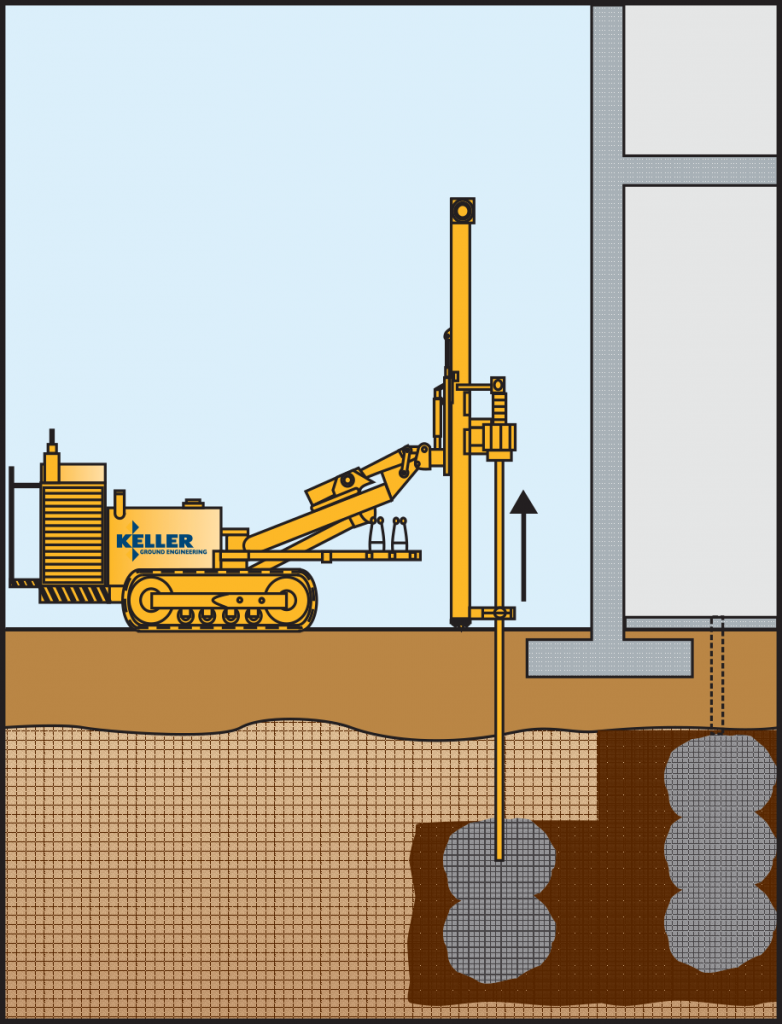

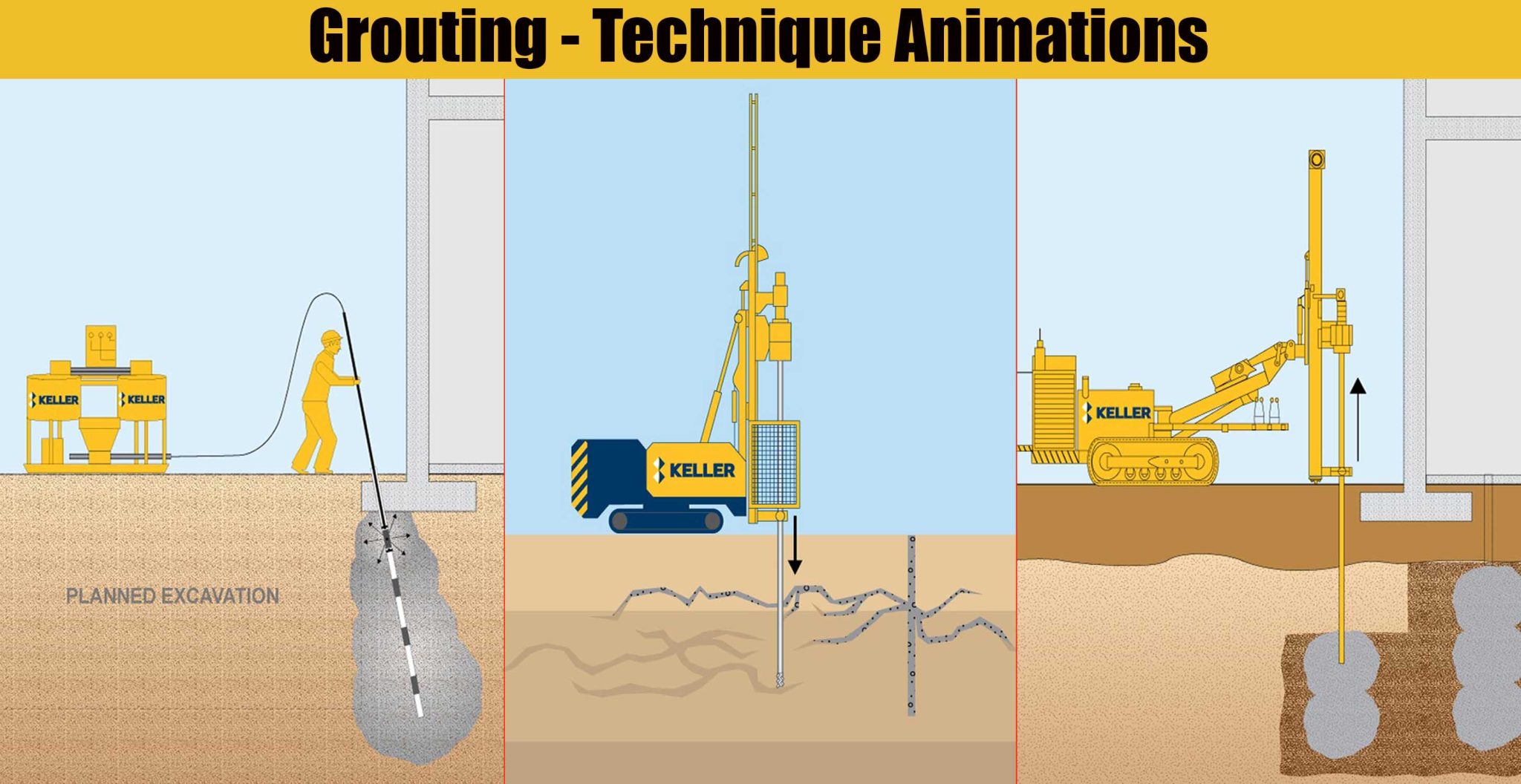

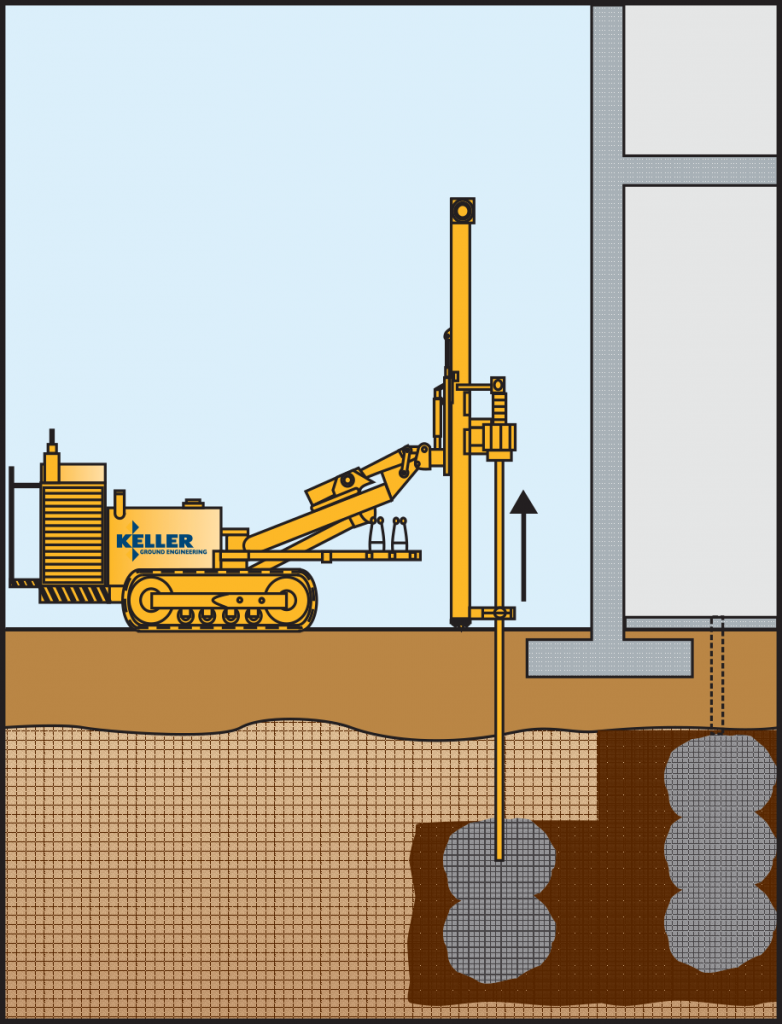

Grouting Technique Animations Engineering Discoveries

1. Prepare the Underside With no other actions or specifications, almost no pump or base manufacturer will have the baseplate's underside properly prepared for the grouting procedure. They will have prepared the surface solely to prevent corrosion in the transit and storage stages. REQUEST INFORMATION - OR - Ask A Question *Indicates a Required Field Grout under machine base plates is used to reduce vibration and maintain structural integrity. Call Epoxy for your next machine base plate grouting project! Grouting Procedures 1. Drill Ports Drill short holes, which is also known as ports, into the cracks/ openings in order to be used as entry and venting terminals. Minimum diameter and depth of ports are 2.5cm and 5cm, respectively. Spacing between holes is 150 mm c/c for finer cracks to 300 mm c/c for others. ARDEX ENDURA offers B 30, a cementitious non-shrink grout and B 50, high strength epoxy grout for grouting all kind of machines base plates. Following is the brief table explaining the properties of the grout which helps to select the grout quickly. Cementitious non shrink, expansive grout. B 31 - cementitious grout attains 10N/Sqmm in 10 Hrs.

Grouting Process

Instructional video on properly grouting a baseplate.Uses Chockfast Red Epoxy GroutFor more information on how to grout rotating or critical equipment system. Column base plates. General machine base grouting. General grouting where the grout can be exposed to mild or moderate concentrations of many industrial chemicals. If required, the grout can be supplied with Sulphate-Resistant Cement. Most situations where a fluid, sanded grout is needed. Installing anchor bolts or tie rods. ADVANTAGES What is Machinery Grouting? Rotating industrial equipment and other types of heavy machinery, can't be simply installed onto a foundation or base. This is due to the irregularities in both the machine base and surface it will be mounted to; such as a concrete floor. It w ill create load-bearing issues and precision alignment difficulties that can become costly and dangerous down the line. 6.6—Safety and handling of epoxies Grout—A mixture of cementitious materials and water, with or without aggregate, proportioned to produce a pour- Chapter 7—Grouting procedures, p. 351.1R-14 able consistency without segregation of the constituents; also 7.1—Consistency a mixture of other constituents (such as polymers) with a 7.2.

Grouting of bases using dura.grout cementitious grouting • abe

A proper foundation with machine grouting will keep the equipment running longer, while requiring less downtime for maintenance and repairs.. Most grout manufacturers offer specific recommendations on the proper underside preparation materials and procedures. Though cementitious grout was often used in the past, epoxy grouts are now more. Now the production grout may be mixed and pumped immediately behind the slurry mix, which is thus evacuated from the hose, and may be retrieved in a bucket. Do not attempt to pump production material through a dry hose. One last word about procedures: Occasionally, no matter how conscientious an operator may be, a hose will get plugged.

Grouting Procedure for Equipment | Base Plate Grouting Purpose: These recommended practices (PIP) are intended to provide recommended procedures, practices and checklist for the installation and pre-commissioning of new and reapplied machinery for petroleum, chemical and gas industry services facilities. The bentonite grout is pumped into the annular space through a tremie pipe that has been inserted to the bottom of the borehole along with the casing. The annular space between the borehole and casing is usually 2 inches or larger. This can vary depending on state regulations, depths and drilling conditions. Grouting is complete when the grout.

jet grouting construction method YouTube

Injection grouting is the method of filling the cracks, open joints, voids, or honeycombs, in concrete or masonry structural members. This is done under pressure with a grout material that cures in place to produce the desired results like strengthening a structure and preventing water ingress. It is desirable to remove enough old grout from beneath the machine so that a load bearing area equivalent to a rail or sole plate mounting can be provided by the epoxy grout once it has been poured. If the foundation itself is cracked, it should be repaired before proceeding further.. Grouting Procedure for Low-Viscosity Epoxy Grout. 1. The.