Metal & Plastic printing available: FDM, MJF, SLS, SLA, Polyjet, DMLS, & Carbon DLS. Get an instant quote in over 70 metal & plastic materials. Free shipping on all US orders. Browse & discover thousands of products. Read customer reviews and find best sellers. Huge Selection & the Latest Styles. Qualified Orders Over $35 Ship Free

Transparent Resin 3D Printing Services Fast Delivery

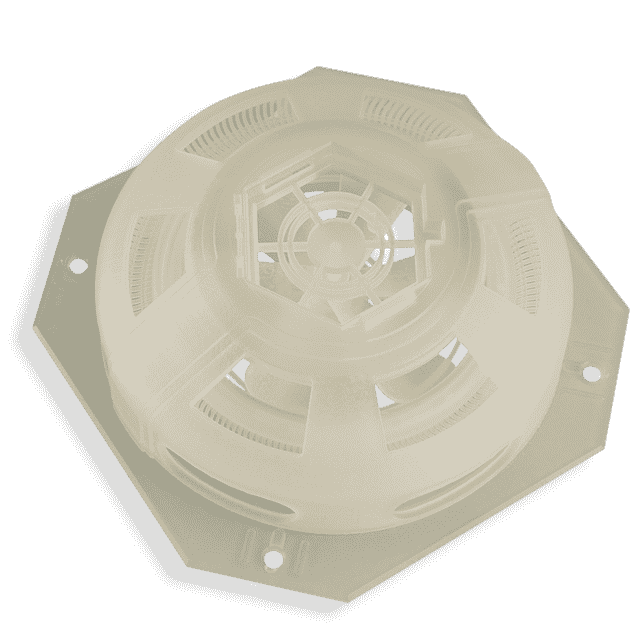

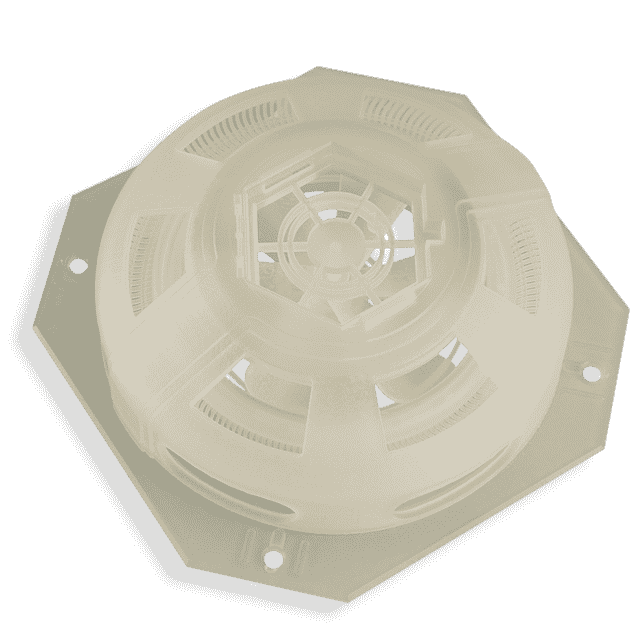

Transparent/Clear 3D Printing - The Ultimate Guide by All3DP Updated Oct 24, 2023 Achieve crystal clear 3D printed parts with our guide to the methods, tips, and best clear resins and filaments for transparent 3D printing. Advertisement with personalized ads Accept and continue Resin 3D-printing is one of the only 3D-printing technologies that can create high resolution transparent plastic parts. One of the challenges in resin 3D-printing is to produce perfect transparent parts that will not yellow over time. Method 1 - Sanding and Polishing The simplest method is to simply sand and polish a finished resin print. This has to be done after the resin print has been through the cleaning and post-curing steps. This technique is quite basic and self-explanatory. Clear and transparent 3D prints are ideal for creating clear prototype parts, showing internal cavities and details, housing LEDs, creating windows, or printing see though anatomical models and medical devices.

3D Printing Material PolyPlus, Transparent Colours, Blue 3dprintingmaterials

Use a clear filament The first component of our mission is the material. Fortunately, this is a pretty straightforward matter. Clear filaments are no longer uncommon. Most of the clear filaments you can buy today are made from PLA, but there are also several options made from PETG or ABS. The material itself doesn't matter. Transparent 3D Printing There are several methods of transparent 3D printing. Hobbyists can rely on clear plastics while working on any project with translucent parts. Below are tips for creating perfect models using clear resin 3D printing, FDM filaments, material jetting, and home materials. Every method can lead to astonishing results. Clear resin 3D printing is a specialized process that utilizes transparent photopolymers to create three-dimensional objects with a high degree of clarity and translucency. Stereolithography is the 3D printing technology behind transparent resin Design tips for 3D printing in transparent resin Obtaining the perfect 3D print in transparent resin is not always easy. But it's possible with these design tips: 1.Minimum wall thickness

MJP BioClear Resin 3D Printing Materials Manufacturing FacFox

Transparent Materials for 3D Printing. Transparent 3D printing relies on specific filaments and resins that offer optical clarity and the desired level of transparency. Below is an overview of commonly used transparent resin and filament materials, including their material properties and considerations: Transparent Filaments: 1. What exactly is transparent 3D printing? Transparent 3D printing refers to 3D printed objects of varying degrees of translucency. The results obtained range from translucent to relatively transparent.

Anycubic High Clear Resin is a special product that provides you transparent resin 3d printing. It significantly improves the yellowing resistance performance of 405nm transparent resin, providing crystal-clear results for users. However, it requires longer exposure time and is more temperature sensitive, compared to standard resins. Resin 3D-printing is one of the only 3D-printing technologies that can create high resolution transparent plastic parts. One of the challenges in resin 3D-printing is to produce perfect transparent parts that will not yellow over time.

PrimaCreator Value Water Washable UV Resin 500 ml Transparent Red 3D Prima 3DPrinters

Dr.3D High Clear Resin. 8. RESIONE G217 Clear Resin. 1. Siraya Tech Simple Clear. One of the best options when it comes to clear resin is the Siraya Tech Clear Water Washable Resin. Some of its best characteristics include: Water Washable. Low Shrinkage. As a guide, we suggest that you increase your wall thickness as your design becomes larger in scale. Small-sized objects, where the sum of dimensions is below 200 mm, need a minimum of 1 mm wall thickness. For medium-sized objects with a sum of the x, y, z dimensions between 200 and 400 mm, the minimum wall thickness is 2 mm.