Use a metal disk, mounted on the camshaft of the engine, with 36 holes (1 actually missing). a led behing the wheel, and a sensor on the front. every time a whole passes in front of the led, it will send a pulse to arduino. that way, by counting holes , you can know at precicce what degrees your engine cycle is. also, by looking for the missing. This project aims to create a flexible, fully featured Engine Management Systems (EMS aka ECU) based on the low cost and open source Arduino platform. Speeduino comprises both the hardware and software components that would be expected from a commercial engine management system, but in an open and low cost package.

Arduino ECU

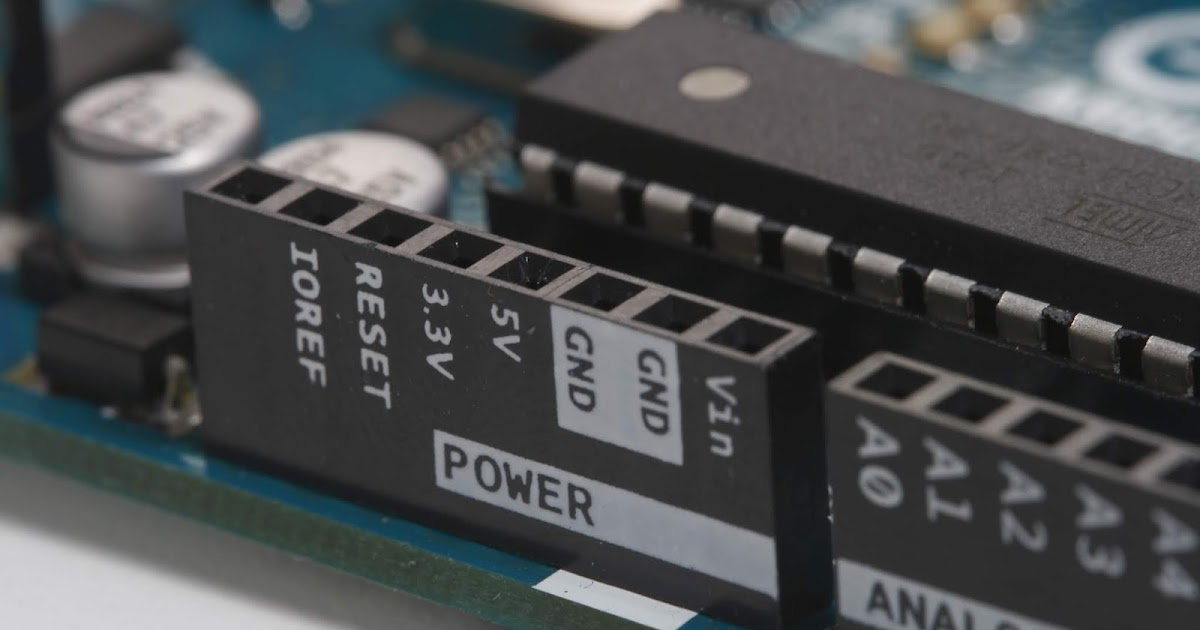

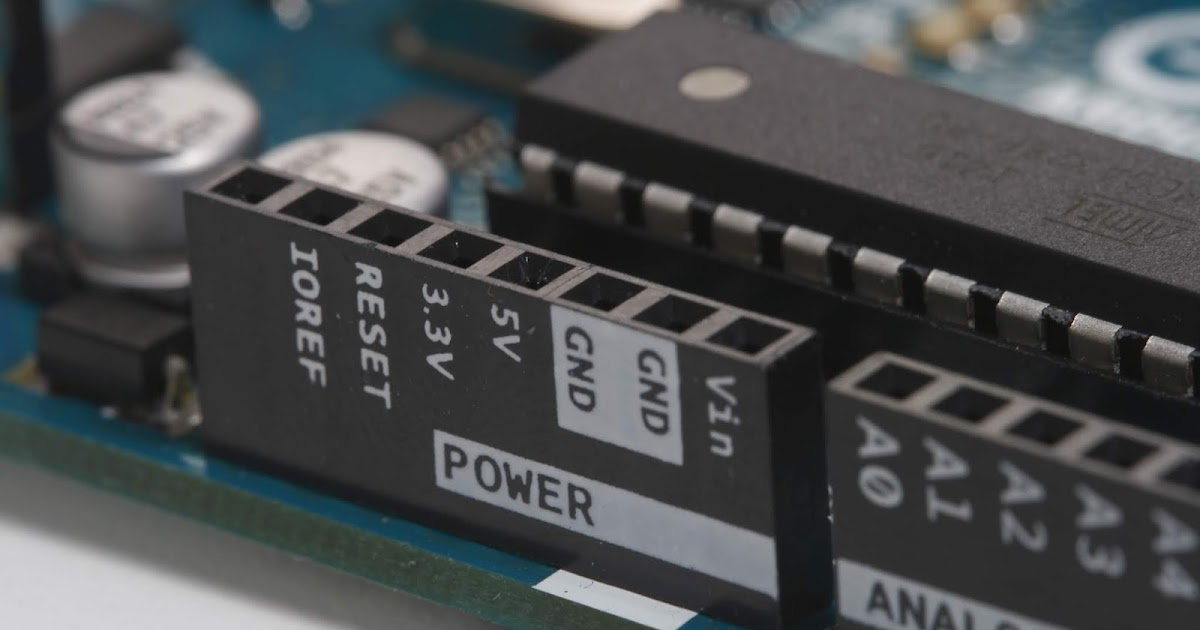

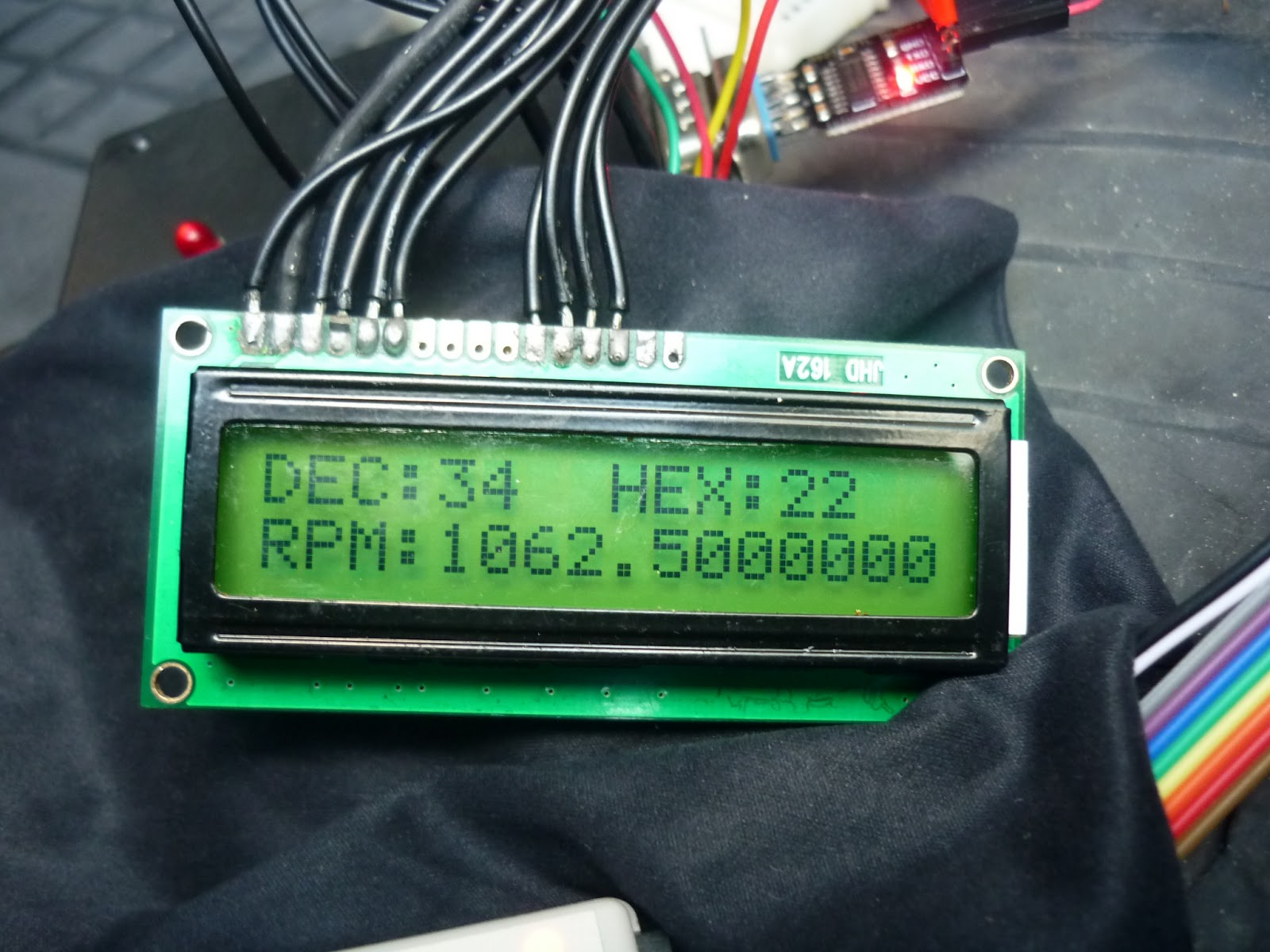

Published March 23, 2021 Using arduino as ecu for small and simple 4 stroke engine Change carburetion system to indirect injection in honda gx390 engine using arduino as ecu Intermediate Work in progress 6,561 Things used in this project Story lyndon evans Making an insanely fast Speeduino ECU Getting Started With A Speeduino ECU - The Complete Basics Guide This led [Fixkick] to create an OBD2 simulator using a secondhand Ford ECU supplied with fake sensor data from an Arduino to persuade it that a real engine was connected. The write-up is quite a. Some notes that might help if you have issues: The baud rate may differ as I'm using an Arduino Uno clone Serial.begin(9600);.. I'm dividing my potentiometer value by ten int potent_rpm = analogRead(A0) / 10; as I had one with pretty high resistance.. The line mcp2515.setBitrate(CAN_500KBPS, MCP_8MHZ); should match the clock that's installed on your MCP2515 module.

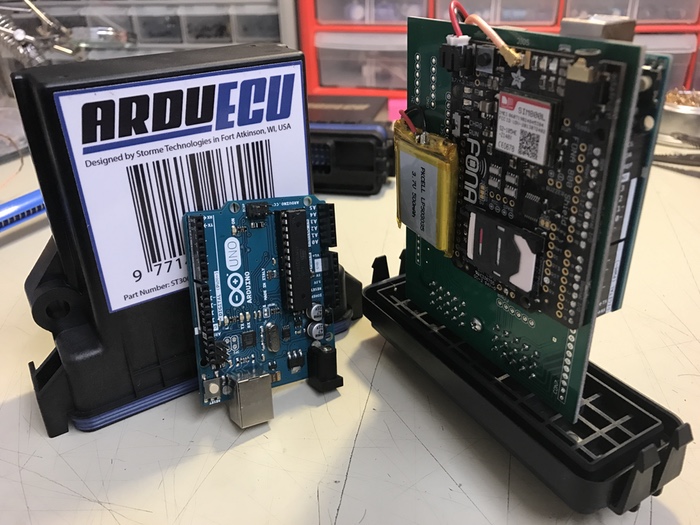

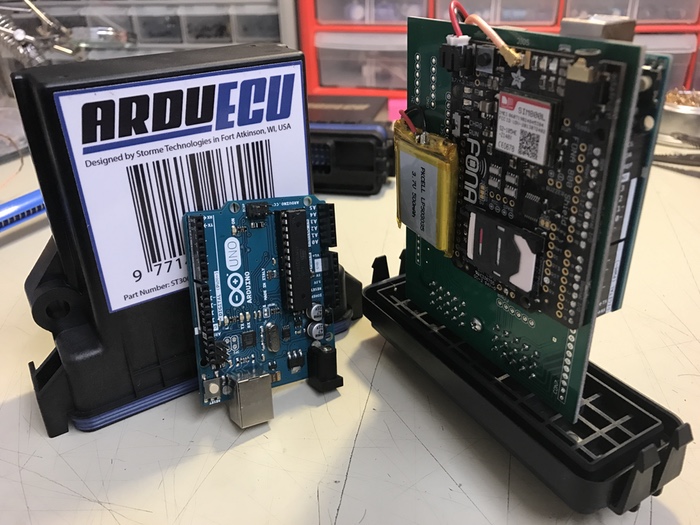

ArduECU,The World's First Waterproof and Rugged Arduino ECUKickstarter M.B Raw

The ECU can be programmed with the Arduino IDE and also supports CoDeSys, meaning you can now configure your ArduECU with ladder logic, functional block, structured text, instruction list, or sequential function charts. ArduECU, now on Kickstarter, comes in three models: - one for basic projects A feature demonstration of the Speeduino ECU firmware as at February 2015. Project page: http://speeduino.comForum: http://speeduino.com/forum This project is made up of a prototype "Rabbit ECU" shield PCB and the Arduino Due controller. The test car is a Holden Barina (Opel Corsa C14NZ engine) but the system should be able to run 1, 2, 4, 6 and 8 cylinder engines. The plan is to create a powerful low-cost open source hobbyist ECU using an up to date ARM micro, CAN bus and LSU4.2 wideband control all for around $100. Right now I have. You signed in with another tab or window. Reload to refresh your session. You signed out in another tab or window. Reload to refresh your session. You switched accounts on another tab or window.

ECU Features Automotive Electronics

Arduino based Open Source Electronic Control Unit for Electric Utility Vehicles Abstract: This paper presents the design and development of a low-cost Electronic Control Unit (ECU), aimed for the application and control of Electric Utility Vehicles (EUV). Danie Conradie. July 2, 2021. [P1kachu] owns a pair of early 1990's Honda's with custom tuning on their stock ECUs, and after having to get the ECU repaired on his '93 civic, he found.

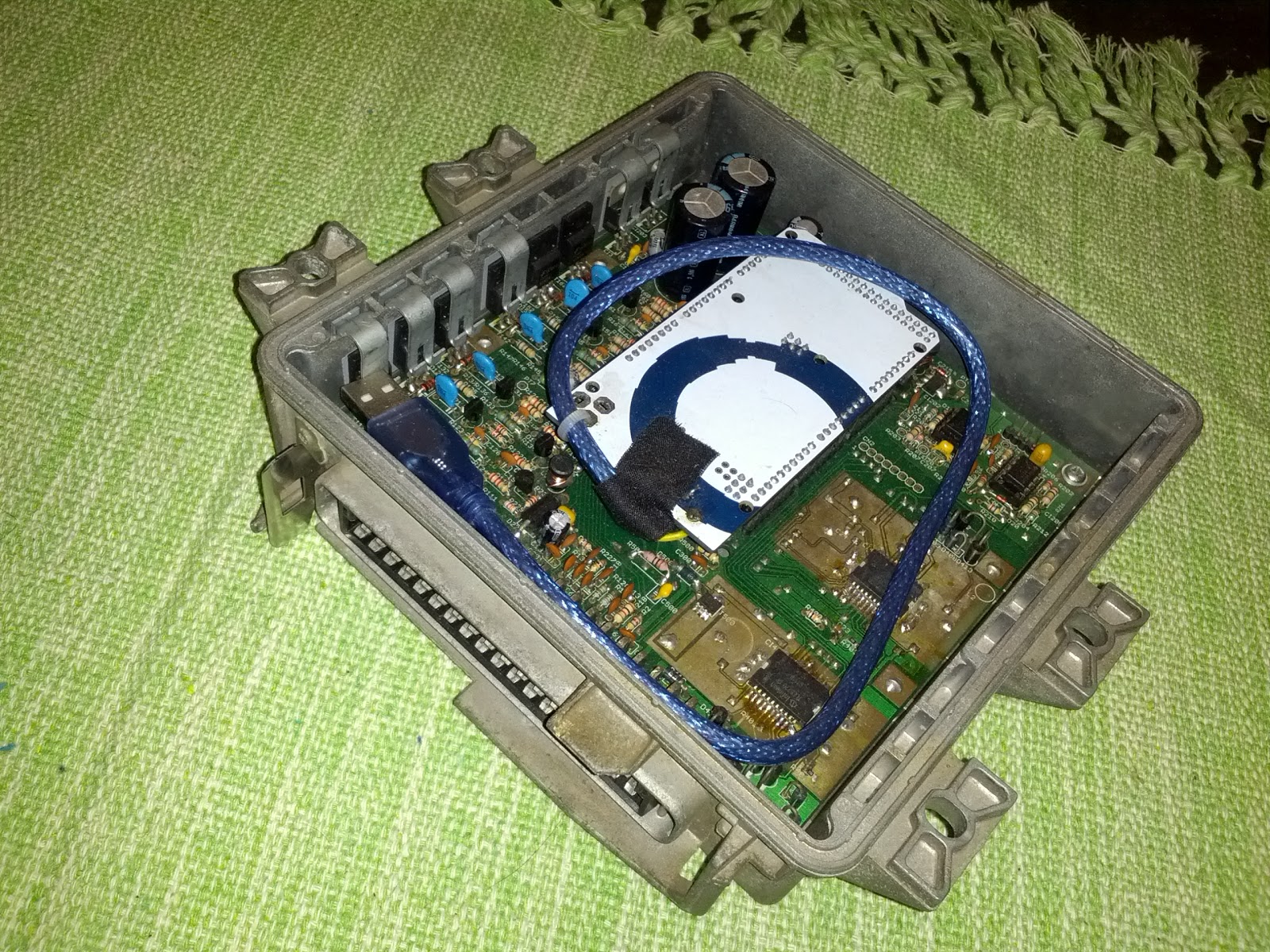

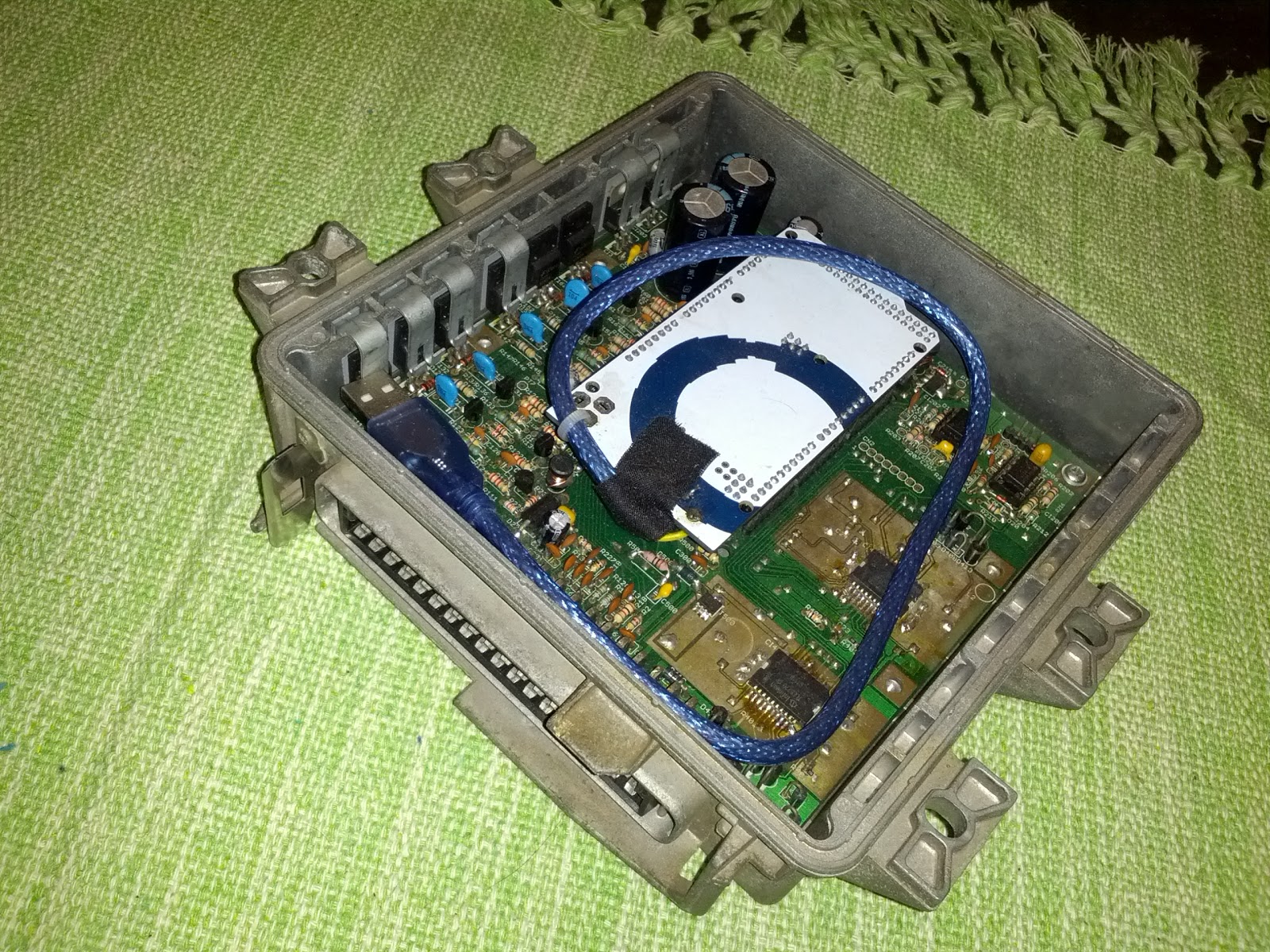

As you can see from his web site, [synkooppi] has created his DIY ECU using an Arduino Mega, which is capable of controlling diesel engines that employ a Bosch VP37 or other inline diesel pump. Jet turbine control unit (ECU) - Arduino (Coding guidance - SORTED) Projects Prop making HaldorLonningdal January 7, 2019, 8:16am 1 Hi. I am using my CNC to machine a few components for my home-built jet turbine, parallell to those efforts I am looking at making a complete ECU (Engine Control Unit) to control and monitor it during ground testing.

Mitsubishi + Arduino = Mitsuduino Onboard Diagnostic Between Mitsubishi ECU Using Arduino

ArduECU is the World's First IP69K Waterproof Rated, Rugged and Durable, Open-Source Arduino-based ECU New breed of Arduino live on Kickstarter! arduino based fully DIY fuel injection ECU. Using Arduino Project Guidance system February 3, 2014, 6:20pm 21 settra: if you had MAF in g/s then (MAF/4)/ (CAMrpm/60) = air grams/rev*cylinder, so you would know exactly how much fuel was needed on each cylinder, based on your desired AFR. Unfortunately MAF sensors don't really give you that.