Injection Molding Animation tronicarts - Multimedia-Agentur 23.1K subscribers Subscribe Subscribed 32K Share 4.5M views 7 years ago A tronicarts 3D-animation which shows the injection. The video shows: the finished plastic part, the injection molding tool, the machine, the injection process and the ejection of the part.If you want to see mo.

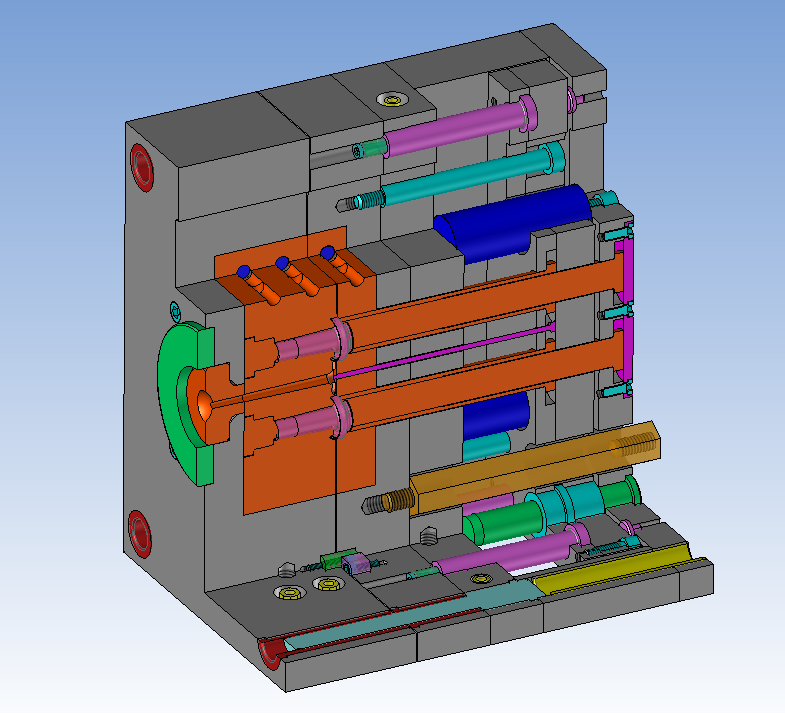

Plastic Injection Mold Design Animation "TwoStage Ejection" Buss Precision Mold

© Paulson Training Programs, Inc.Watch stunning, dynamic 3-D graphics for Paulson's intensive, "Technology of Injection Molding" series of eLearning injectio. 4 steps of plastic injection molding process, with animation explained by boyanmfg September 26, 2023 manufacturing knowledge, Plastic molding Introduction to the Injection Molding Process Steps Injection molding, often referred to simply as "molding," is a fundamental manufacturing process used to create plastic products. The injection press; The mold and its components; Important concepts: daft angle and parting line; How clamping works - toggle vs. hydraulic clamping; How the polymer is pushed into the mold (details about the screw mechanism, with a cool animation) For more in-depth explanations on the way gates work, you can watch another video . 2. Injection Molding Simulation in Fusion 360 features the typical things you would expect in a simulation workflow; the ability to animate results, probe values of data, compare different design or manufacturing options, and the ability to magnify deformations. However, Fusion 360 users can also benefit from additional powerful features like.

Injection Molding What It Is, How It Works, Who Is It For Ouranoscloud

Plastic Injection Engineer brings easy-to-use injection molding simulation directly to the designers of plastic parts and injection molds. It simulates how melted plastic flows during the injection molding process to predict manufacturing-related defects on plastic parts. You can quickly evaluate manufacturability while you design, to eliminate. Injection molding is a method for manufacturing high-volume parts with plastic materials. Due to its reliability and flexibility in design options, plastic injection molding is used in many industries, including: packaging, consumer and electronics, automotive, medical, and many more. Injection molding is a method to obtain molded products by injecting plastic materials molten by heat into a mold, and then cooling and solidifying them. The method is suitable for the mass production of products with complicated shapes, and takes a large part in the area of plastic processing. What is Moldex3D Plastic Molding. The leading true-3D molding simulation software can be applied in a wide range of plastic molding processes. We can predict potential manufacturing defects, validates part/mold design, lowers mold development costs, evaluates manufacturability, shortens time-to-market, and greatly increases business value. One.

Plastic Injection Molding Service Online Rated 4.9/5 by more than 165 Clients in 2020

John Wesley Hyatt won the prize — worth around $3 million in today's money — by patenting a system to mold billiard balls from celluloid. And the plastics revolution had begun. There are plenty more fun facts in this video, along with animations explaining the injection molding process. The video, which was first posted on YouTube in 2015. https://sositarmould.com/https://www.moldchina.com/Plastic injection molding is the most common method for mass manufacturing of plastic products, The princi.

Check the coil packing solution with a leading manufacturer for the professional solution just here: In today's fast-paced and competitive manufacturing industry, efficiency and precision are key factors for success. One innovative technology that has revolutionized the production process is the Plastic Injection Molding Machine. This cutting-edge machine enables the… Watch on Welcome to the video tutorials of mechanisms by mekanizmalar. Modern plastic injection machines are true robotic devices and can operate 24 7 without a human intervention. Plastic materials the size of small grain granules are loaded into the hopper, either manually or via a pumping device in regular intervals.

Sino Manufacturing Solutions Plastic Injection Moulding Animation YouTube

It's a method of plastic injection where molten plastic is inserted into a mold to produce a part in the shape of the mold cavity, creating a physical representation of modeled plastic parts. Plastic injection molding has been around since the late 19th century and continues to be popular. What Are the Basics of Plastic Injection Molding? The basics of plastic injection molding process includes creating the product design, making a tooling a mold to fit the product design, melting the plastic resin pellets, and using pressure to inject the melted pellets into the mold. See a breakdown of each step below: 1.