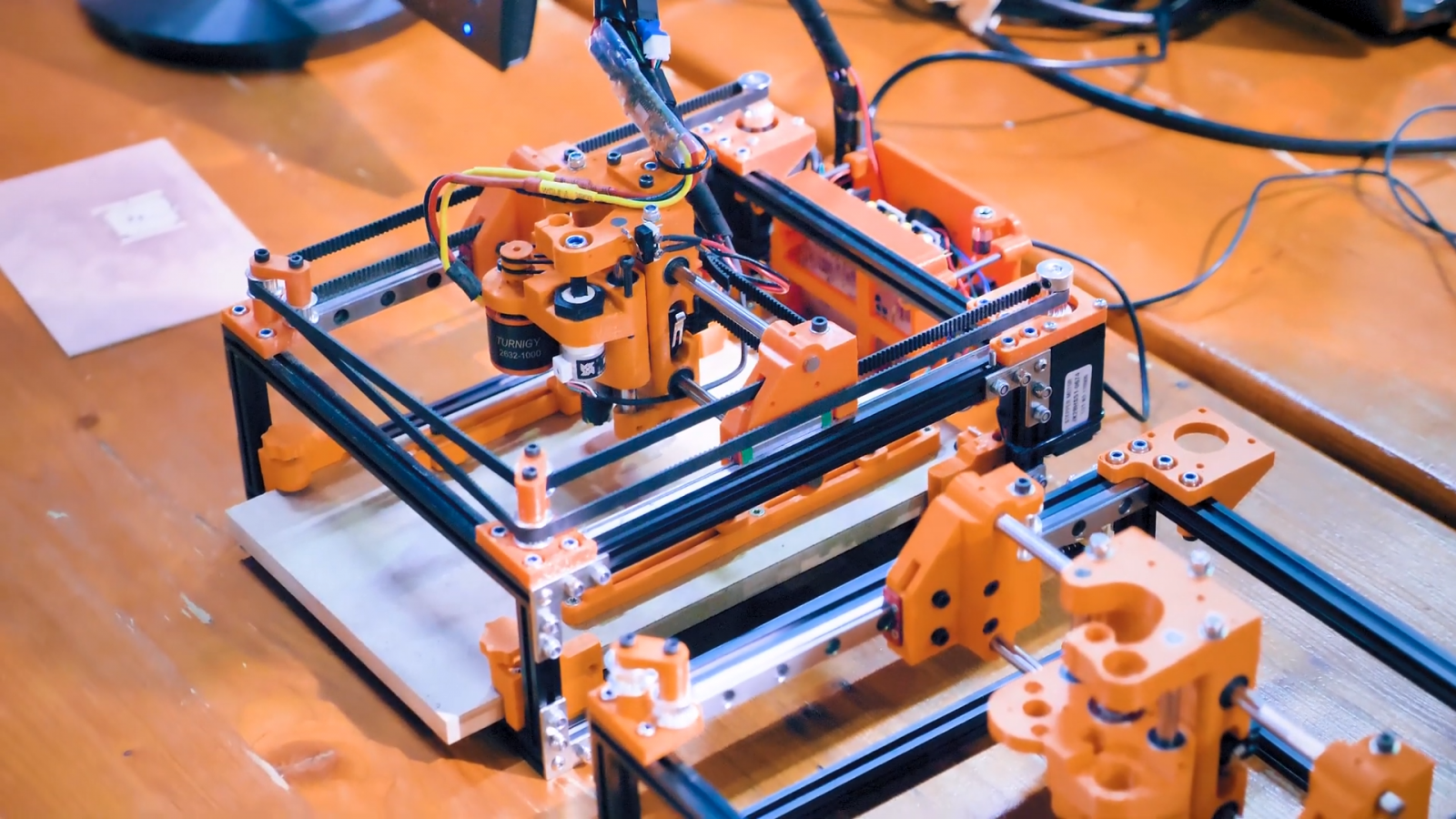

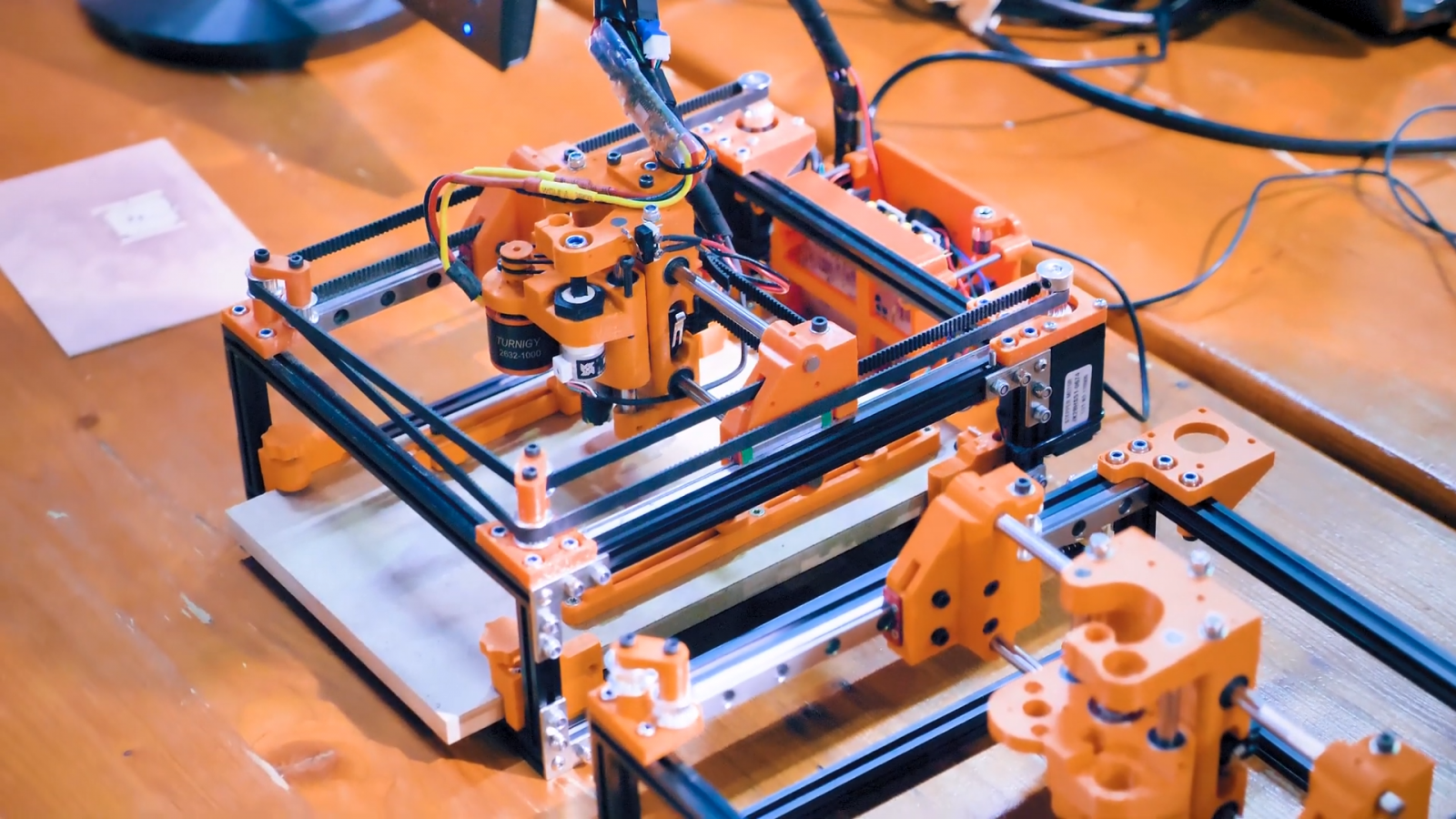

At this year's Make Munich, I found the ANT CNC - a custom, minuscule CNC made just to mill PCBs with the best precision possible! It's completely open sourc. Tiny CoreXY PCB mill! (that actually works) Watch on At this year's Make Munich, I found the ANT CNC - a custom, minuscule CNC made just to mill PCBs with the best precision possible! It's completely open source, too, and small enough to store in a drawer once you're done. Source on Bitbucket Ant CNC YouTUbe channel Discuss the Project on the Forum

Tiny CoreXY PCB mill! (that actually works) makemunich Tom's 3D printing guides and reviews

Tiny CoreXY PCB mill! (that actually works) 6-21 screenshot. 2019-03-10 Nils Hitze. Post navigation. Tiny CoreXY PCB mill! (that actually works) #makemunich. About. Tom's 3D is published by New Media Thomas Sanladerer and covers new developments in consumer and professional 3D printing. Fresh guides, reviews and projects are published every week! ----Find us on the internet:Website: https://www.bantamtools.com/Order now at: https://store.bantamtools.com/collections/desktop-cnc-machinesLinkedin: https:. Small Portable PCB CNC Machine (CoreXY) Build in ' CNC ROUTER BUILDS ' published by ymilord, Jun 24, 2015 . This is a small CNC mill/router specifically for manufacture PCBs. This is based on the corexy gantry setup. The plan is to have a small, light self-contained machine that can be used and easily but away when it's job is done. Tiny CoreXY PCB mill! (that actually works) 1-24 screenshot (1) 2019-03-10 Nils Hitze. Post navigation. Tiny CoreXY PCB mill! (that actually works) #makemunich. About. Tom's 3D is published by New Media Thomas Sanladerer and covers new developments in consumer and professional 3D printing. Fresh guides, reviews and projects are published every.

Tiny CoreXY PCB mill! (that actually works) makemunich Tom's 3D printing guides and reviews

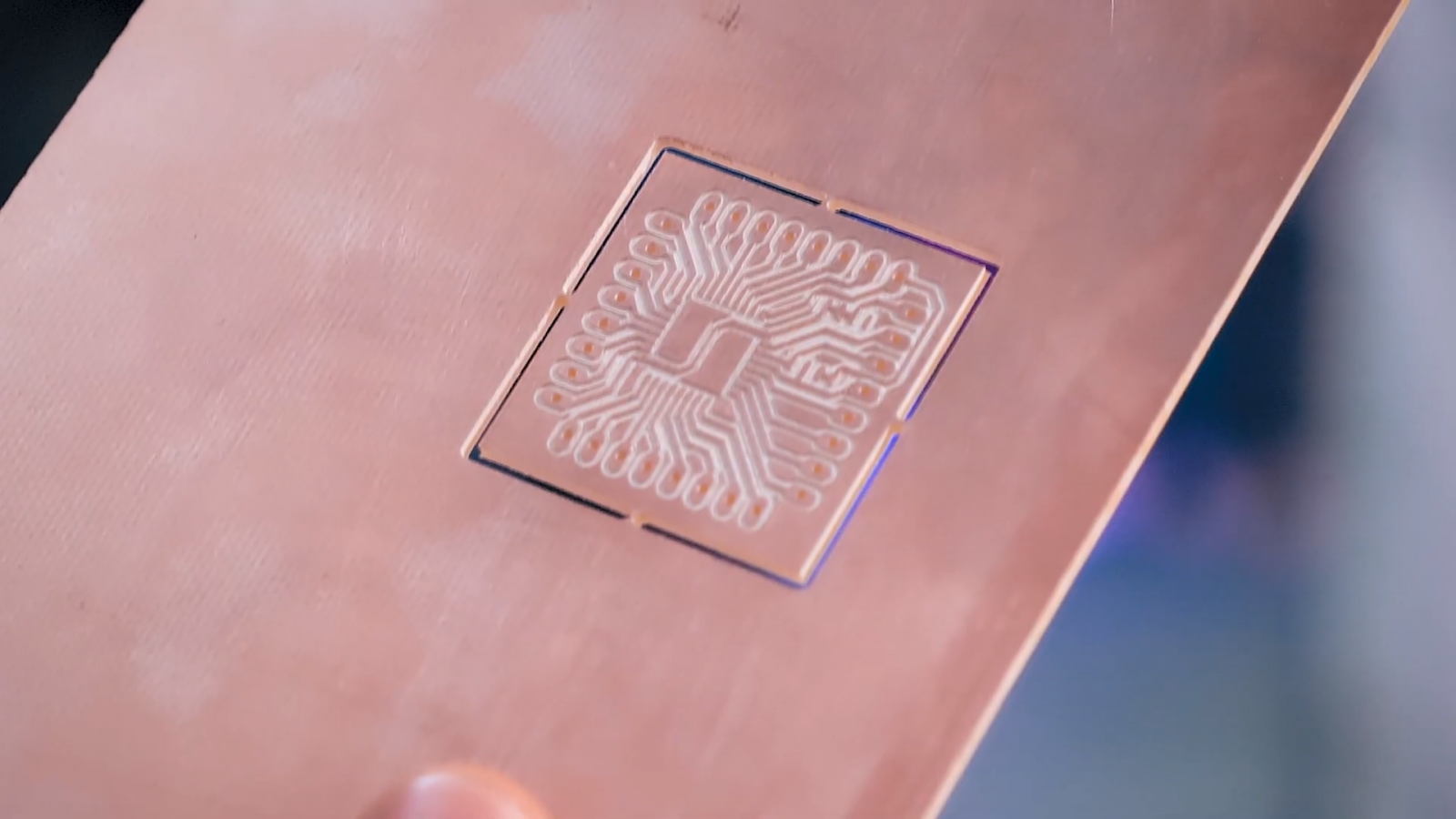

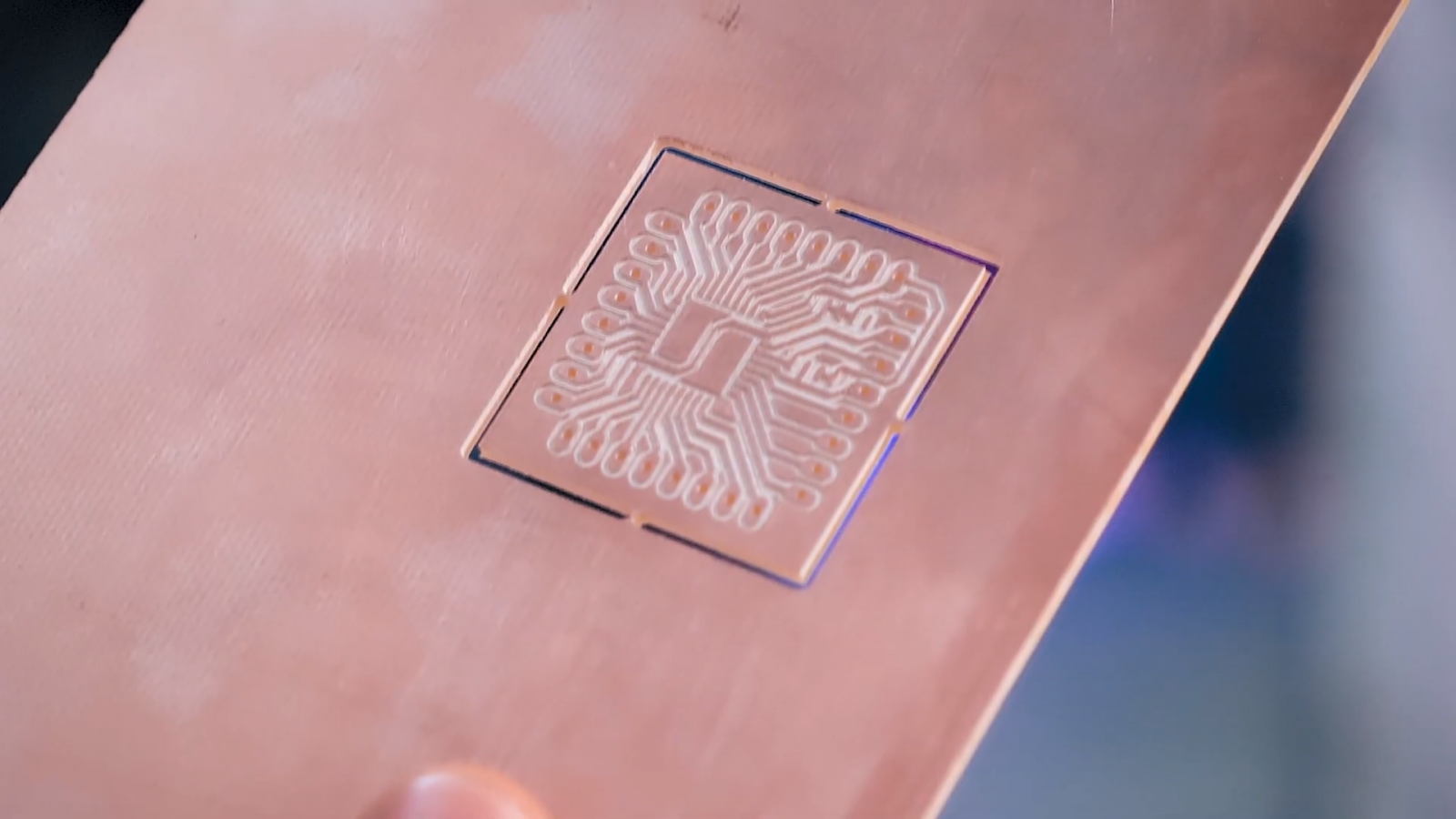

Tiny CoreXY PCB mill! (that actually works) #makemunich. About. Tom's 3D is published by New Media Thomas Sanladerer and covers new developments in consumer and professional 3D printing. Fresh guides, reviews and projects are published every week! Find additional material and full transcripts to the content on YouTube here. A compact and affordable CNC that any maker can build by themselves! This machine is dubbed "The Ant" or "Compact PCB Maker" and is mainly designed to create custom. The ANT (Compact PCB Maker) Users Group - A Tiny CoreXY PCB CNC Be warned, this mill is pretty expensive — anywhere from $2,500 to $3,000. The company claims it is a better choice than a conventional cheap mill because it uses a 26,000 RPM spindle and has. 1. Using toner transfer and chemical etchant -- can be tricky to get the right materials, and the chemicals are nasty and messy 2. Paying a service like BatchPCB or OshPark -- fairly inexpensive, but usually have to wait a long time, like two or three weeks. Milling them on a CNC is a quick way with a different set of pros and cons: The good:

Tiny CoreXY PCB mill! (that actually works) makemunich Tom's 3D printing guides and reviews

Ways to increase milling speed Double-Sided Boards While single-sided PCBs are simple and ideal to use when possible, many circuits require two sides. Double-sided boards offer a wide variety of possibilities for circuit board designers because they have more surface area and flexibility when routing traces. The electronics in their place. The power supply is located one level below the other electronics. After all the necessary parts were sorted out, still one problem had to be solved. Namely the dust and noise produced by the milling process.

The problem is that even a small spindle (usual dremel or other small hand tool) is too much for such kinematics. Mekinizem • 3 yr. ago Currently the plan is to beef up the x gantry if the system can't handle the forces from PCB milling, but the Ant PCB mill appears to be running a similar system. The Rough Idea. The EDM process. The end-effector will be something like a 3D printer extruder without the heater. X-Y axis movements will be done using core-xy. Or will be a simple X-Y movement assembly. The end effector will also act as a probe for profiling the surface of the PCB for the 'auto-bed-level' function.

smallXY Experimental CoreXY 3D printer

Tiny CoreXY PCB mill! (that actually works) January 24, 2020 John Hand Tool Sets 21. Previous. Untouchable. Next. Michael's Pyramid Scheme - The Office US. 21 Comments Zo Fryer says: January 24, 2020 at 4:47 am I cut pcb's on a fiddly 3018 I made. It's not bad. It also has a laser. tazacnc best cnc maichine best cnc maichine