Free 2-day Shipping On Millions of Items. No Membership Fee. Shop Now! Create control joints no farther apart than 24 to 30 times the slab thickness and at no time greater than 15 feet along both the width and length of the slab by pressing a 1-inch deep grooving tool into the surface. Joint spacing greater than 15 feet requires the use of load transfer devices such as dowels or dowel plates.

E5SMEW25 Concrete Ground Bearing Floor, Insulation below Slab LABC

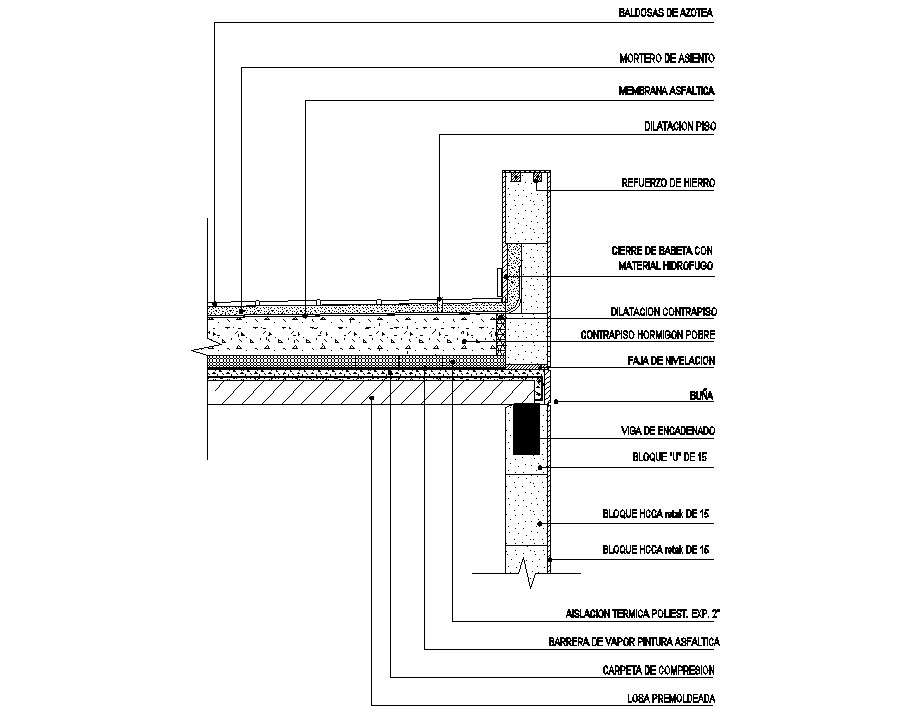

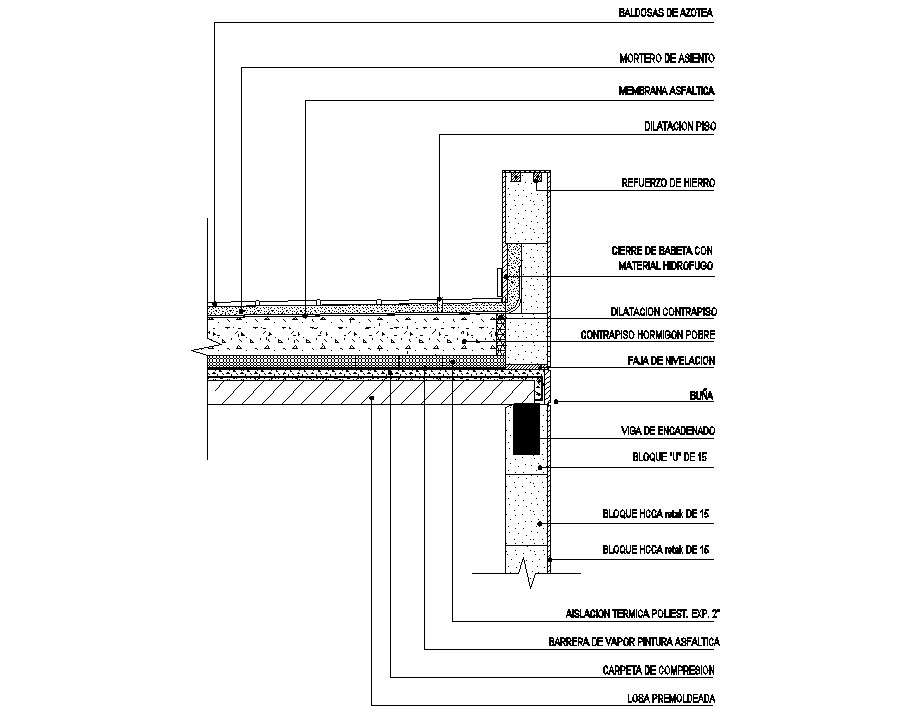

The quality of a concrete floor or slab is highly dependent on achieving a hard and durable surface that is flat, relatively free of cracks, and at the proper grade and elevation. Properties of the surface are determined by the mixture proportions and the quality of the concreting and jointing operations. Concrete Floor Slab In typical office environments, the concrete floor slab itself is comprised of 4" to 6" thick concrete reinforced with one layer of welded wire fabric at mid depth, unless below the water table, when hydrostatic heads may exert upward pressure, requiring stronger construction. The ground bearing concrete floor slab is supported by the load bearing strata below. The slab abuts but is not tied to the external walls. The build up of this type of system can typically be: Hardcore fill to compacted to create suitable level (approx 200mm thick) Damp proof membrane (DPM), often laid over sand binding Concrete Slab on Ground Design and Details Minnesota Concrete Council October 13, 2020 Scott M. Tarr, PE FACI

[email protected] 1 Guidance to Concrete Solutions NORTH S ETARR CONCRETE C. •Isolate Floor Slab-Perimeter Walls-Dock Levelers-Slab Penetrations-Interior Columns, Drains, Plumbing, Electrical •Joint Material-Compressible

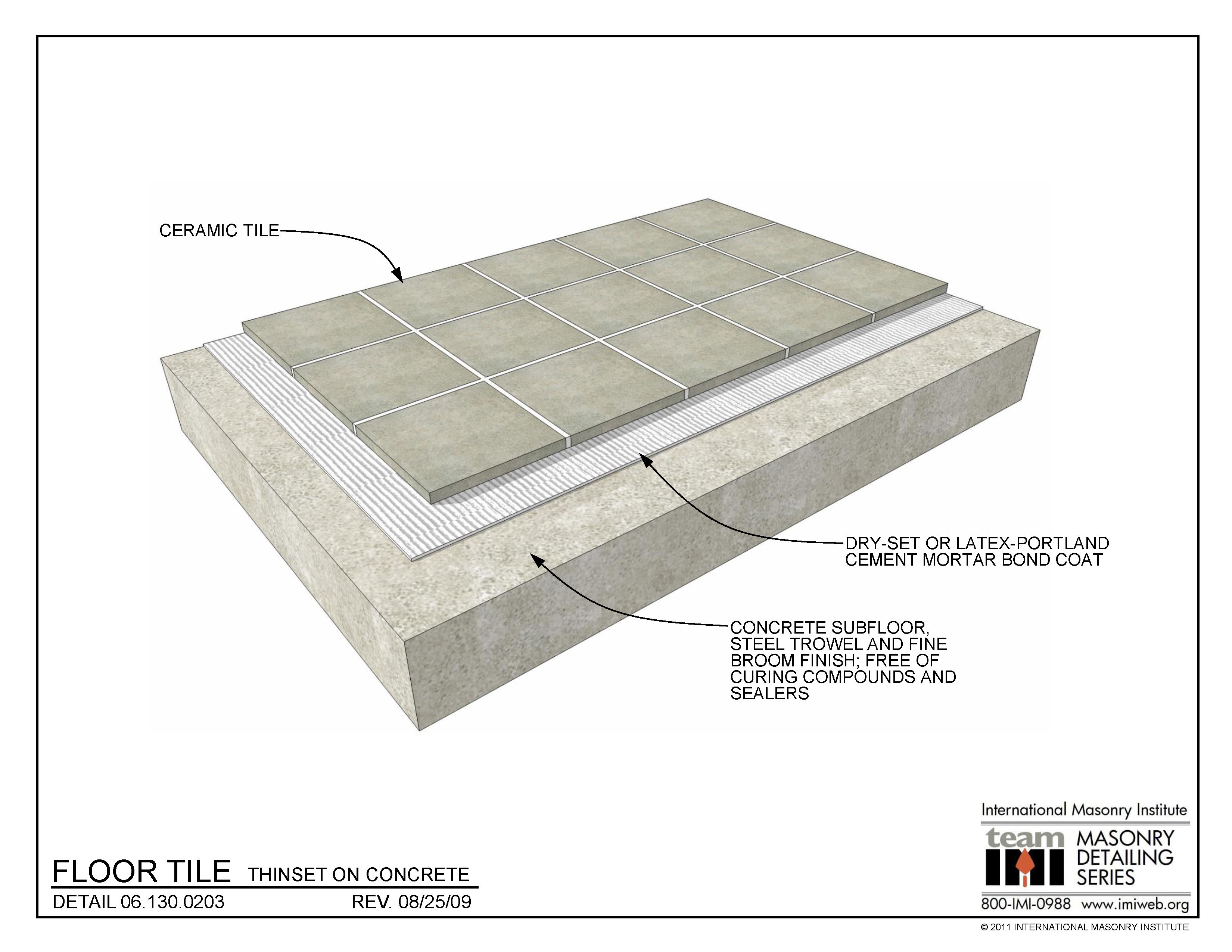

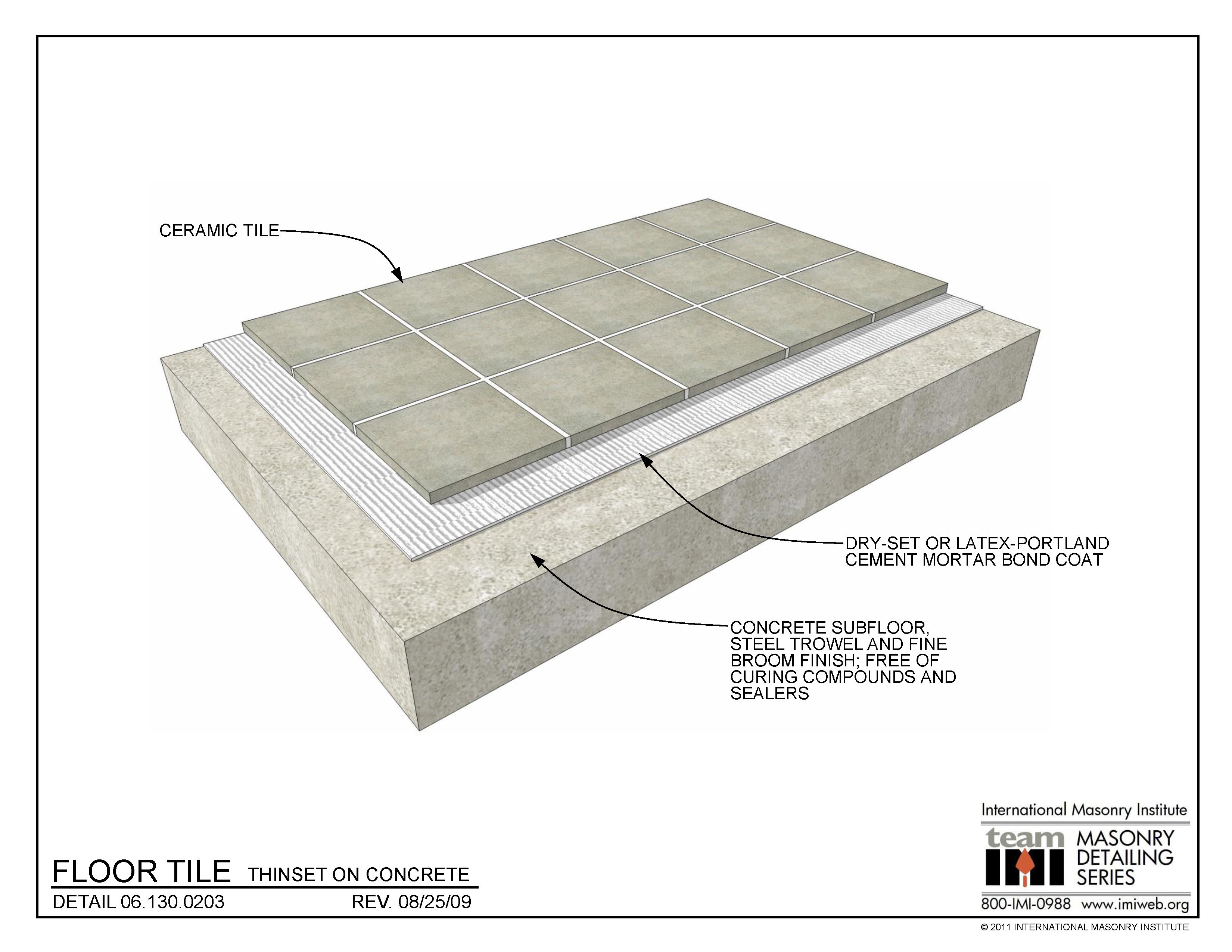

06.130.0203 Floor Tile Thinset on Concrete International Masonry Institute

Concrete floor slab construction process includes erection of formwork, placement of reinforcement, pouring, compacting and finishing concrete and lastly removal of formwork and curing of concrete slab. Concrete Floor Slab Construction Process Assemble and Erect Formwork Prepare and Place Reinforcement Pour, Compact and Finish Concrete Details for Concrete Masonry Preface Annotated Design and Construction Details for Concrete Masonry Page A-2 Preface DISCLAIMER NCMA promotes the use of concrete masonry in part through the development and dissemination of technical information. This manual was compiled to assist designers in preparing concrete masonry construction details. Two-Way Concrete Floor Slab with Beams Design and Detailing Design the slab system shown in Figure 1 for an intermediate floor where the story height = 12 ft, column cross-sectional dimensions = 18 in. x 18 in., edge beam dimensions = 14 in. x 27 in., interior beam dimensions = 14 in. x 20 in., and unfactored live load = 100 psf. The mesh reinforcement in the slab is placed in the top with 1" covers. The slab is constructed on well compacted granular fill, crushed stone or marl. Figure B-10: Alternative Floor Slab Detail. The suspended reinforced concrete slab is tied into the external capping beam at floor level. The top (steel) reinforcement is important.

E5SMEW23 Suspended InSitu Concrete Floor, Insulation below Slab LABC

The quality of a concrete floor or slab is highly dependent on achieving a hard and durable surface that is flat, relatively free of cracks, and at the proper g. 5.3—Suspended slabs. 5.4—Miscellaneous details. CHAPTER 6—SITE PREPARATION AND PLACING ENVIRONMENT. 6.1—Soil-support system preparation. 6.2—Suspended slabs. Costs can range from $2 per square foot for a basic to $30 or more for high-end artistically rendered floors. Basic design: $2 to $6 per square foot. A basic concrete floor design includes pouring the slab or overlay, then a basic polishing and single colorizing treatment (staining or dyeing).

If you took an advanced concrete design course, you probably had a good introduction to the design of two-way slabs.Although all multi-story buildings require multiple small slab penetrations for routing of plumbing, fire protection piping, and ductwork between floors and larger openings for stairwells and elevator shafts, your course probably c. Concrete Floors, Slabs Ground Floor Slab Types 1. Solid Floating Concrete Ground Floor Slab A solid floating concrete ground floor slab should only be used if the depth of granular fill is less than 900mm. Diagram B51 - Typical detail of solid floating concrete ground floor slab 2. Cast In-Situ Suspended Ground Floor Slab.

Download Concrete Slab Section CAD Drawing Cadbull

Concrete slabs on grade are a very common type of concrete construction. Floor slabs can range from a simple residential basement slab to a heavy-duty industrial floor. T-SLAB ® is an all-new, patented precast concrete slab system that leverages the time-tested principles of Roman arch design and multiple concrete types to deliver a stronger, lighter, and more versatile slab. This groundbreaking product was designed to deliver all the advantages of concrete and the industry's most effective building materials in a single, cost-effective, and 100% precast.