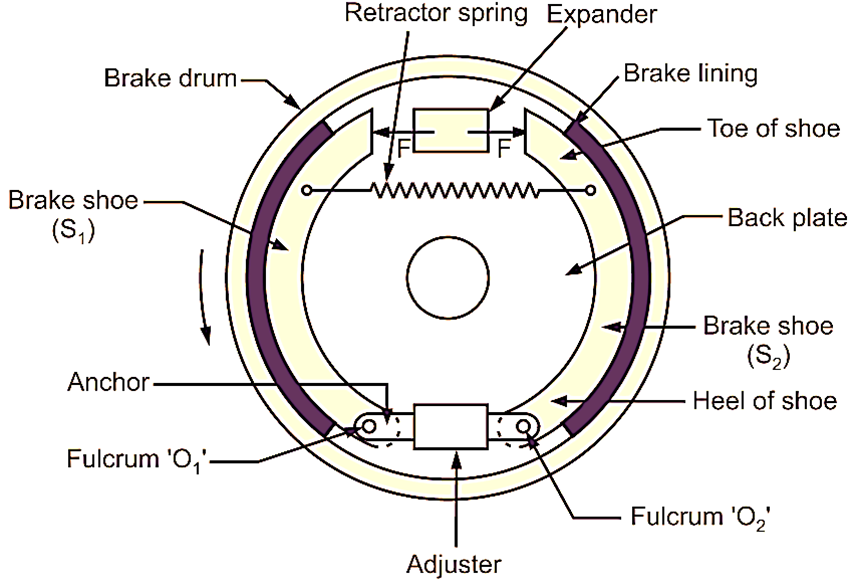

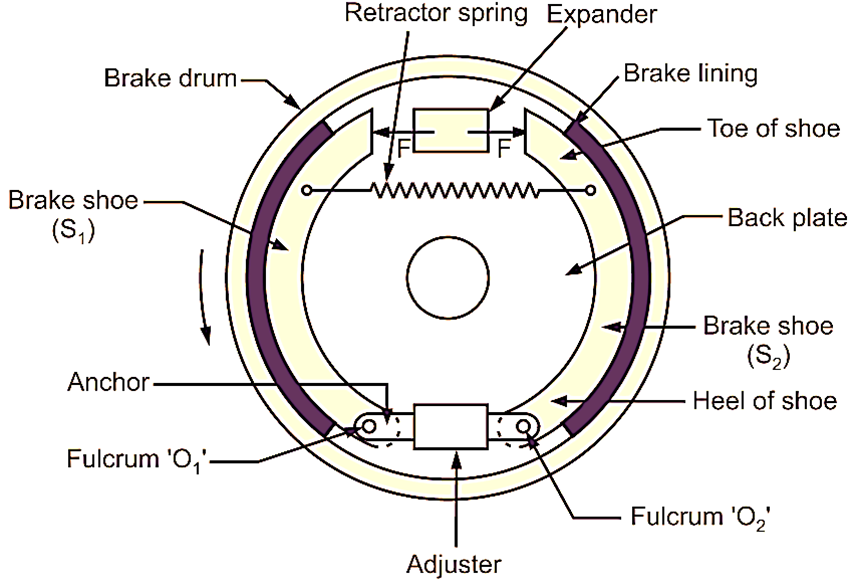

A brake drum is a rotating, cylinder-shaped part that exerts pressure outwardly on a set of shoes or pads to produce friction. Drum brakes are brakes where the shoes press against the inner surface of the drum. When shoes contact the outside of the drum, it is commonly referred to as a clasp brake. The drum brake diagram below shows how all the parts of the brake work together. For more brake topics and links to related auto articles, check out the links below. Related HowStuffWorks Articles How Brakes Work 1. 5 6 Print | Citation

Drum Brake Diagrams 101 Diagrams

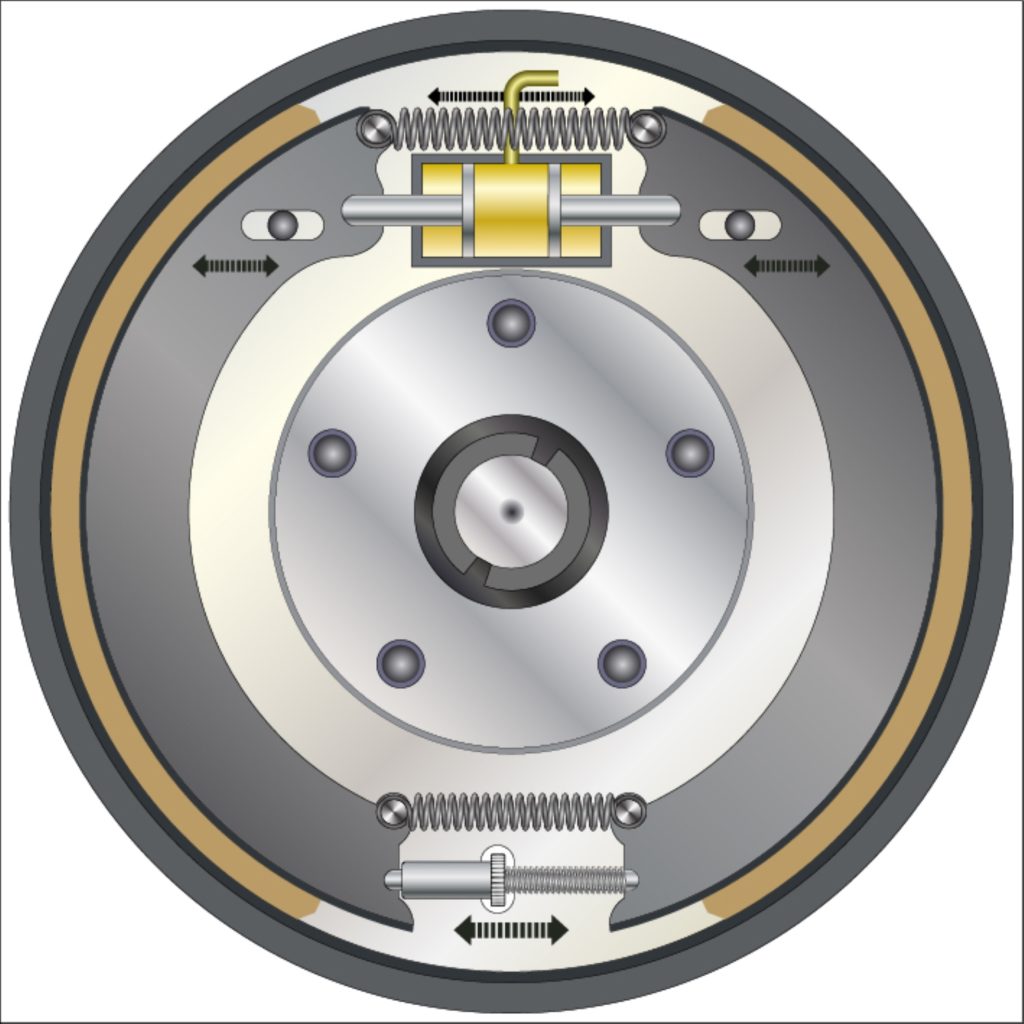

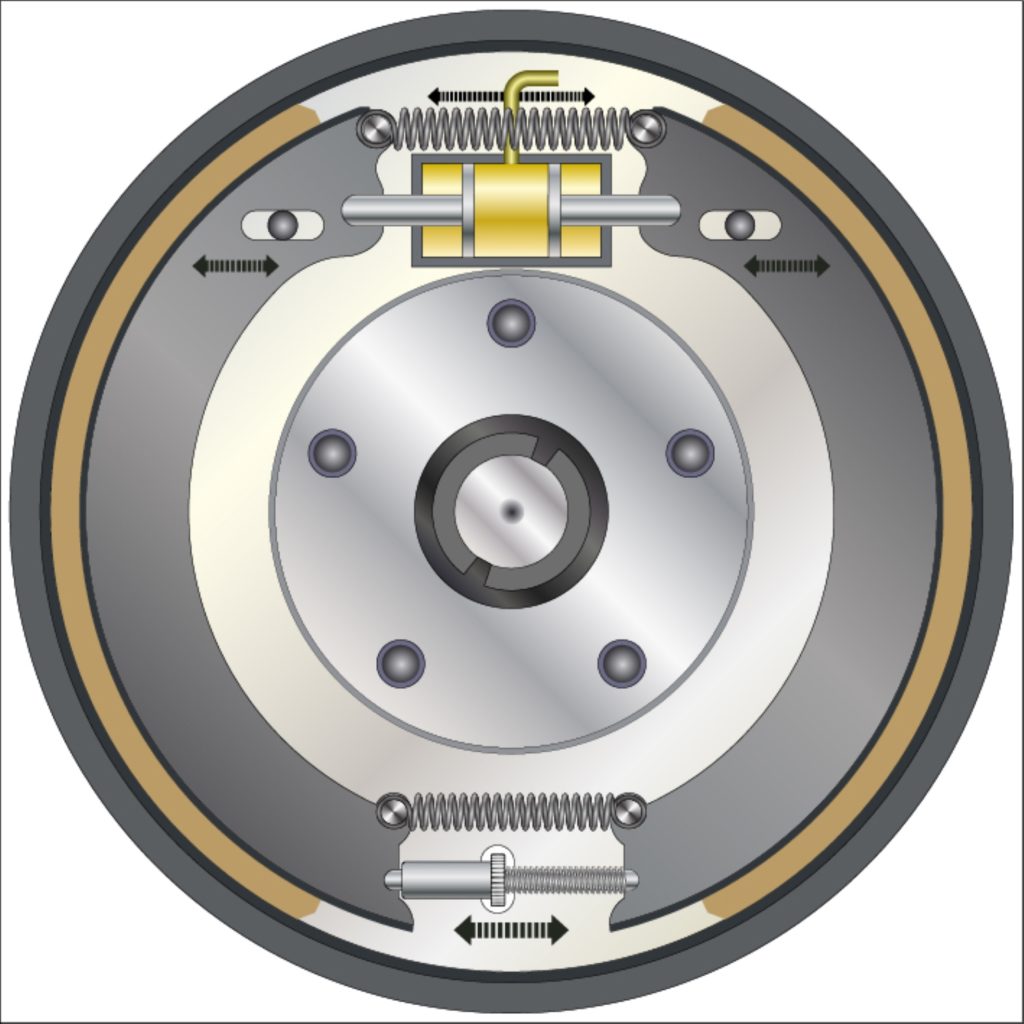

Begin the assembly process with the wheel cylinder (s). They're installed as shown here. They can only go in one way. During assembly, it's a good idea to lightly lube the pushrods. They're definitely subject to corrosion. (Image/Wayne Scraba) Diagram of Drum Brakes Drum brakes are a brake system with brake drums (rotor) that rotate with the wheels. Inside each drum are brake shoes fitted with brake linings (friction material). Pistons (pressure mechanism) press against the drums from the inside to generate braking force, thus making it possible to decelerate and stop the vehicle. First, the basics: When you hit the brake pedal, the piston pushes the brake shoes against the drum. That's pretty straightforward, but why do we need all of those springs? This is where it gets a little more complicated. Many drum brakes are self-actuating. Braking System Basics Basics of Disc Brakes Two Types of Disc Brakes: Floating & Fixed Basics of Drum Brakes Drum vs. Disc Brakes Brake Maintenance What Is a Simple Brake System Master Cylinder: Contains a piston assembly and brake fluid. Brake Fluid: Transfers the hydraulic pressure. Disc Brake Assembly: Includes caliper, pads, and rotor.

Drum Brakes Diagram

https://www.aacdelavan.com/automotive-services/drum-brakes/ Location of drum brakes. Drum brakes work on the same principle as disc brakes: Shoes press against a spinning surface. In this system, that surface is called a drum. Many cars have drum brakes on the rear wheels and disc brakes on the front. Drum brakes have more parts than disc brakes and are harder to service, but they are less expensive to. Discover the different parts of a drum brake system with the help of a detailed diagram. Understand how each component works together to create friction and slow down the rotation of the drum brake. Learn about the drum, shoes, wheel cylinder, springs, and other important components in this informative article. A ratchet on the handbrake lever keeps the brake on once it is applied. A push button disengages the ratchet and frees the lever. On drum brakes, the handbrake system presses the brake linings against the drums. Engine Block 18 minutes. Stop wasting time on YouTube and get serious!

Drum Brakes vs. Disc Brakes Learn Their Difference In The Garage with

Drum brake replacement. Learn how to replace your drum brakes including the wheel cylinder and bleeding the brakes. This is the only video you need to watch. Figure 6. Adjuster mechanism For the drum brakes to function correctly, the brake shoes must remain close to the drum without touching it.

1 Put on an asbestos respirator. The work you're about to do involves finely-ground brake dust or asbestos dust, and breathing it can be extremely hazardous to your health. Get a mask that's designed for the job of filtering asbestos, not a simple paper one you might use in a shop. Send the kids and pets away, too. A drum brake is a type of mechanical braking system commonly used in vehicles to slow down or stop their motion. This braking mechanism operates through the interaction of friction between brake shoes and the inner surface of a drum-like component attached to the wheel.

Drum Brakes vs. Disc Brakes Learn Their Difference In The Garage with

A drum brake for road vehicles consists of a number of lined shoes located within a drum that rotates with the wheel. To slow or stop the vehicle the shoes are pressed against the inside surface of the drum to create a friction force.. Figure 8 Diagram showing possible shoe resultant positions . Irregular lining wear or unbedded linings are. 1. Backing plate: Provides a solid base for other components in the drum brake attached to the axle sleeve. 2. Brake drum: Bolted to the wheel hub and spins with the wheel. Often made of cast iron, and is resistant to heat and wear.