For many years the light emitting diode (LED) has been a popular choice for use in status displays and matrix panels. Now, you can choose among recently developed blue and white types (widely used in portable devices) as well as the ubiquitous green, red, and yellow types. 1. Provide stable and reliable output voltage, and the output current can be adjusted according to the size of the load. 2. Light weight and small size. LED circuit boards are lightweight and small in size, which means you can use them in projects that require small, lightweight LED PCBs. 3. Adjust the brightness of each lamp bead easily.

/DSC_4048a.jpg)

17mm 5Mode LED Driver Circuit Board for Flashlight DIY

An LED printed circuit board is used to mount the diode (s) and power the LED for the application. Generally, LED devices use a surface-mounted design (SMD) that includes a single LED component. To generate more light, an LED circuit board connects multiple lights. Introduction LEDs are all around us: In our phones, our cars and even our homes. Any time something electronic lights up, there's a good chance that an LED is behind it. They come in a huge variety of sizes, shapes, and colors, but no matter what they look like they have one thing in common: they're the bacon of electronics. LEDs circuit board: 7 things you need to know Are you struggling to decide on a LEDs circuit board supplier? Let's see if we can help. In this post, we cover the benefits of LED PCBs and their applications. Wn e also discuss material selection and production issues. The LED board manufacturing process is difficult, and there is a lot to consider. Printed circuit boards are a technology that plays a valuable role in supporting LEDs. These are thin boards made of fiberglass, metals or other materials that electrically connect electronic components. These boards, often called PCBs, are essential to many LED applications.

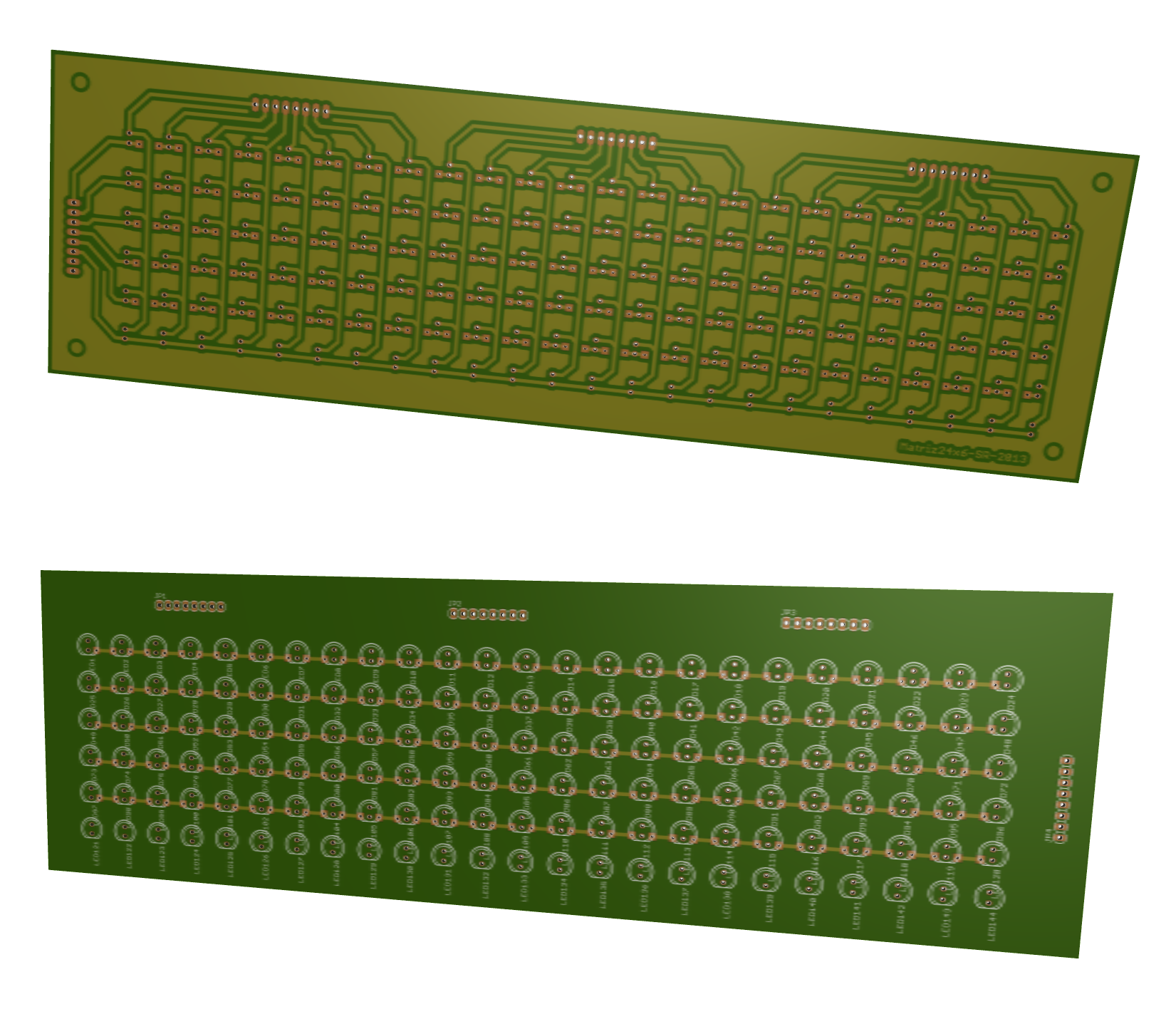

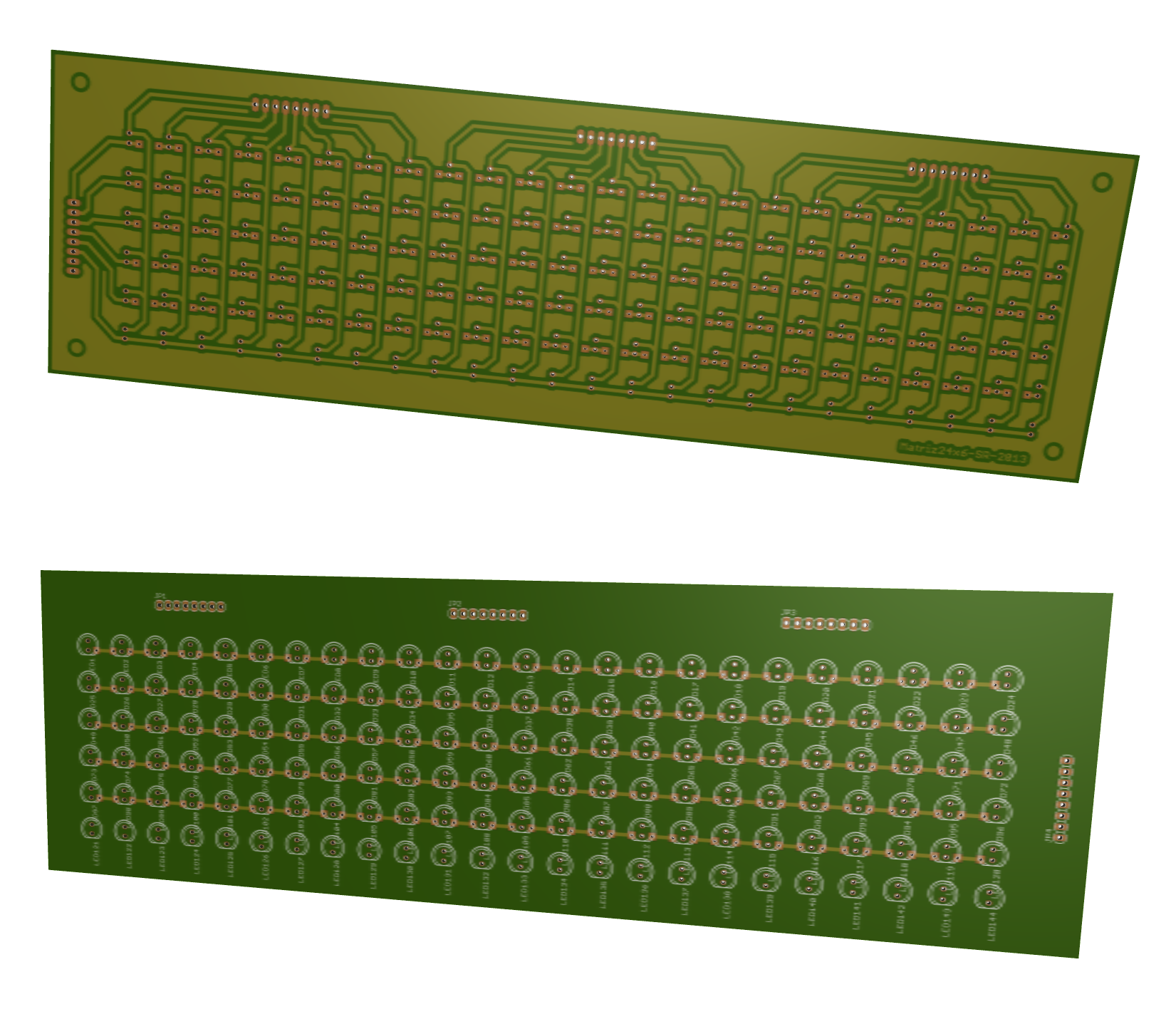

24x6 LED Matrix Control Circuit ElectronicsLab

LED PCBs, also known as LED circuit boards or LED light circuit boards, are specialized printed circuit boards designed to provide electrical connections and mechanical support to LEDs. They are a robust platform for mounting and interconnecting LEDs, ensuring they function optimally to produce the desired illumination. What is the LEDs Circuit Board? Light-emitting diode, abbreviated as Led, is an increasingly common lighting technique in the digital age. Led is solid-based lighting that transforms electric current into light with the help of a semiconductor. You should solder a lead to a PCB to make a led circuit board. An LED is an electronic component commonly known as a light-emitting diode that converts electricity into light energy. As LED is a complex component, it demands a special circuit board to fulfill the criteria of uninterrupted performance. The LEDs produce excessive heat, operate high currents, and require a sturdy base to be laid on and for. LED driver boards can be simple to design when you have the best set of PCB layout features at your fingertips. Learn more about designing LED circuit boards with Mark Harris. You can build this type of high-power LED PCB design with Altium Designer's complete set of circuit board layouts and manufacturing tools. Power System Design for LED PCBs

220V LED Printed Circuit Board Assembly Aluminum Bulb Light PCB With SMD 2835 5730

Embedded LED PCB. SMD LED circuit boards. A wide range of finishes - SMOBC/HASL, electrolytic gold, electroless gold, electroless silver, immersion gold, immersion tin, and OSP. Option of base plate - Copper or Aluminum. Choice of PCB Core - FR-4, Epoxies and aluminum laminated with copper. Dielectric thickness: .003". November 30, 2022. A LED PCB board is a printed circuit board (PCB) that is specifically designed to house and connect light-emitting diodes (LEDs). Unlike traditional PCB, LED PCBs are specially designed to provide electrical and thermal management. This is important because LED are sensitive to heat, and excessive heat can cause the LED to.

The LED is soldered to the circuit board and features a chip that creates the light when electrically connected. A thermal heat sink and a ceramic base are used to bond the chip. It is difficult for an LED PCB board to cool with traditional methods because it tends to create a high volume of heat. Aluminum LED circuit boards, also called aluminum PCBs or metal-core PCBs, are made to use for LED applications.They have an aluminum base and Beneficial than FR4 or fiberglass-based PCBs.. 1. Thermal Management: Aluminum is good conductive for heat so used in LED projects. LED components generate heat during creation effective heat management is required for loner working operation.

5mm LED Board from ptudor on Tindie

What is LED Circuit Board? The term "LED" refers to semiconductor diodes that produce visible light. Soldering the LED to the PCB allows the chip that generates the light, which is directly connected to the electrical current. The chip gets glued onto a ceramic base, which gets attached to a heat transfer sink. Step 1: 3 Volt Basic LED Circuit With 10 Ohms Resistor. The above diagram shows a 3V LED circuit, in this circuit there are two AA cells are used. When you are operating an LED with 3V you have to use minimum 10 ohms resistor . For more details visit Simple Basic LED Circuit Ask Question Step 2: 6 Volt Basic LED Circuit With 390 Ohms Resistor.

/DSC_4048a.jpg)