Mill finish aluminum refers to the original, unpolished state of the metal that has not been treated or finished in any way. This form of the metal is largely untouched, with the surface often appearing somewhat dull. Mill finish aluminum has not undergone any further processing after being produced from raw aluminum through an extrusion process. Mill-finish aluminum is utilized in the automotive industry for various applications, including trim, body panels, and structural components. The lightweight and corrosion-resistant nature of aluminum makes it an ideal choice for mill finish surfaces in automotive manufacturing. Importance of Mill Finish Cost-Effectiveness:

What is Mill Finish Aluminum, and How Does it Compare?

Mill finish aluminum is used to describe aluminum with no post-processing. The surface of the freshly extruded aluminum profile is a mill finish. In fact, that's where the term originates, raw metal coming from mill rollers without surface treatment. Mill finish is also found in aluminum extrusions. Mill finish is the surface texture (or finish) of metal after it exits a rolling mill, extrusion die, or drawing processes, including sheet, bar, plate, or structural shapes. This texture is usually rough and lacks lustre; it may have spots of oxidation or contamination with mill oil. #1 - Mill Finish At first, all aluminum extrusions have a mill finish. This reflects the state of the aluminum after it leaves the extrusion die. Die and tooling marks, a dull appearance, oxidation, and white "rust" can all be present on the aluminum after extrusion. What Is Mill Finish Aluminum? Aluminum that has been extruded from a mill has a natural finish called mill finish. It lacks any protective coating or external surface, making it the most basic type of aluminum. Window and door frames, gutters, siding, and other goods can all be found with an aluminum mill finish.

What is Mill Finish Aluminum, and How Does it Compare?

Mill finish aluminum means the extrusion products without any surface treatment; it is a simple product after extrusion processing in the extrusion press, it is bare aluminum extrusion. "Mill Finish" is the natural appearance of the aluminum as it comes from the rolling mill (Alcoa, Reynolds, Kaiser, or Alcan) or the extrusion mill. It is "as is" with no external mechanical or chemical finishing. Extruded metal is considered "mill finish". All aluminum has an oxide of some varying thickness. Mill finish aluminum is your best economical choice for non-corrosive environments and if outward appearance isn't a priority. In comparison, clear anodized aluminum — or other colors — provides better: Aesthetics Surface durability Resistance against corrosion (e.g., salt, water and UV light) Technically, mill finish aluminum or mill finished aluminum, has the finish that it came off the mill with, so it doesn't have an actual finish. That doesn't mean mill finished aluminum isn't attractive and doesn't have its purpose.

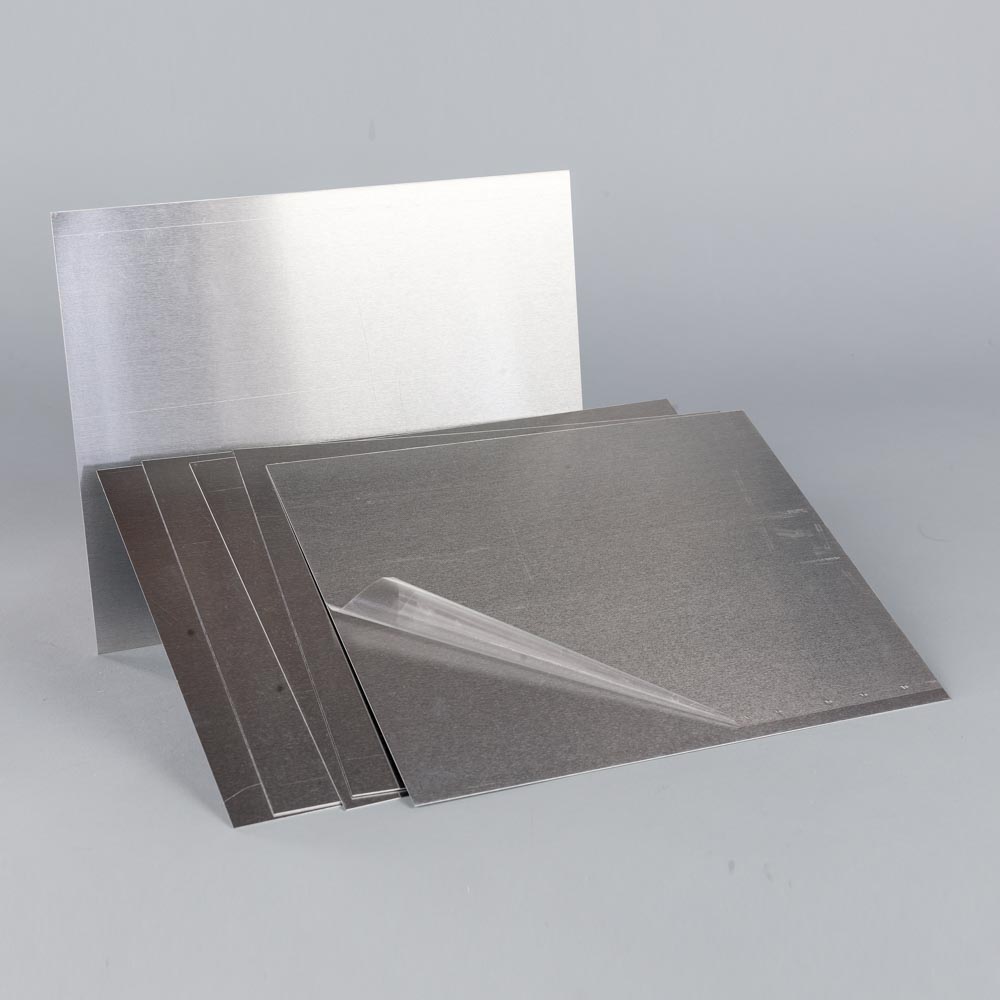

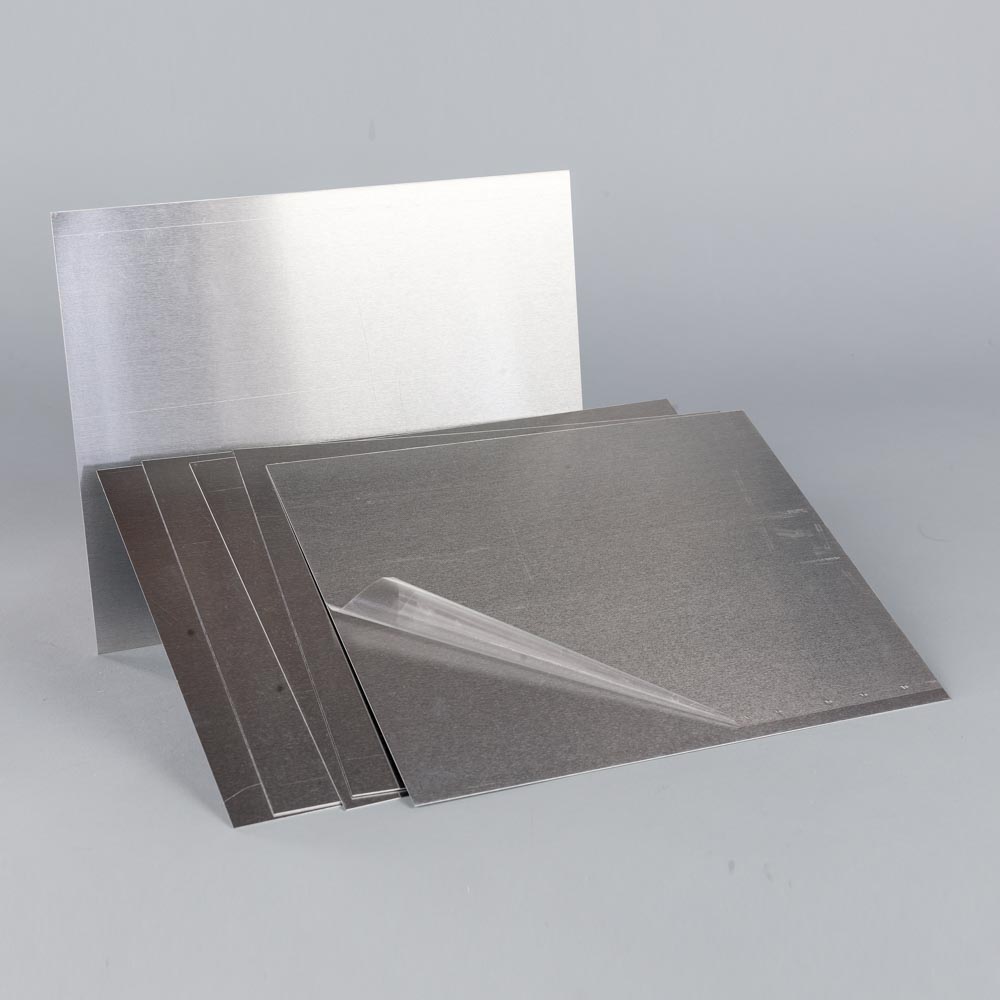

Mill Finish Aluminum 5/13×19 DASS Art

Aluminium extrusion mill finish is a semi dull / semi reflective finish. It often has lines running along the length of the extrusion but these can be limited by specifying the visible surface during the drawing and sample process. Mill finish aluminum is the natural appearance of aluminum as it comes from the rolling mill. We offer aluminum sheet and foil gauges in a wide variety of alloys, tempers and finishes. These products can be supplied in both coils and cut lengths. We also supply brazing alloys and clad metals.

Mill finish is the natural finish that aluminum profiles have as they emerge from the extruder die.It's basically bare aluminum. The appearance is natural color of aluminum and it is sliver, as without any surface treatment, there will be some die lines and marks on the surface and it is widely used in the inner decoration and inner parts of finished products. Construction. Mill finish aluminum is used in buildings as aluminum trim, window frames, door locks, gutters, and drains.. Electrical Components. Mill-finish aluminum is not the best electrical conductor when compared with metals like copper or iron but compared with other aluminum finishes like anodized aluminum, it offers better conductivity.

Mill Finish Anodising Quality Aluminium Sheet 55HX™ 5005 AQ H14

Watch on Learn aluminum milling basics, from choosing the right end mill for your aluminum milling application, to the differences between aluminum grades and more. Understanding the vital role mill finish aluminum sheets play in numerous industries requires a sneak peek into their production process. Let's take a quick look at the steps involved: 1. Raw Material: Bauxite Mining. All aluminum products have their roots in bauxite, a reddish-brown rock abundant in the Earth's crust.