A run-around coil is a type of energy recovery heat exchanger most often positioned within the supply and exhaust air streams of an air handling system, or in the exhaust gases of an industrial process, to recover the heat energy. A run around coil loop simply moves heat from one air stream to another via two heat exchangers and a heat transfer medium, usually water or glycol. A pump is required to move the medium through the system.

RunAround Coil System Example Layouts. Download Scientific Diagram

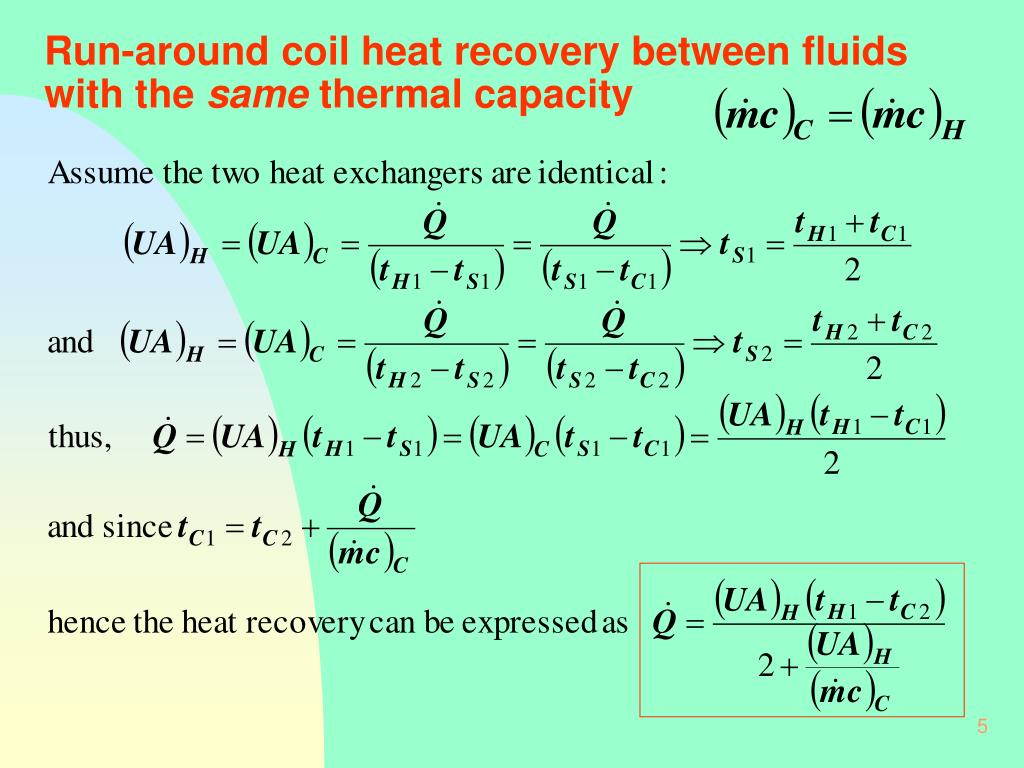

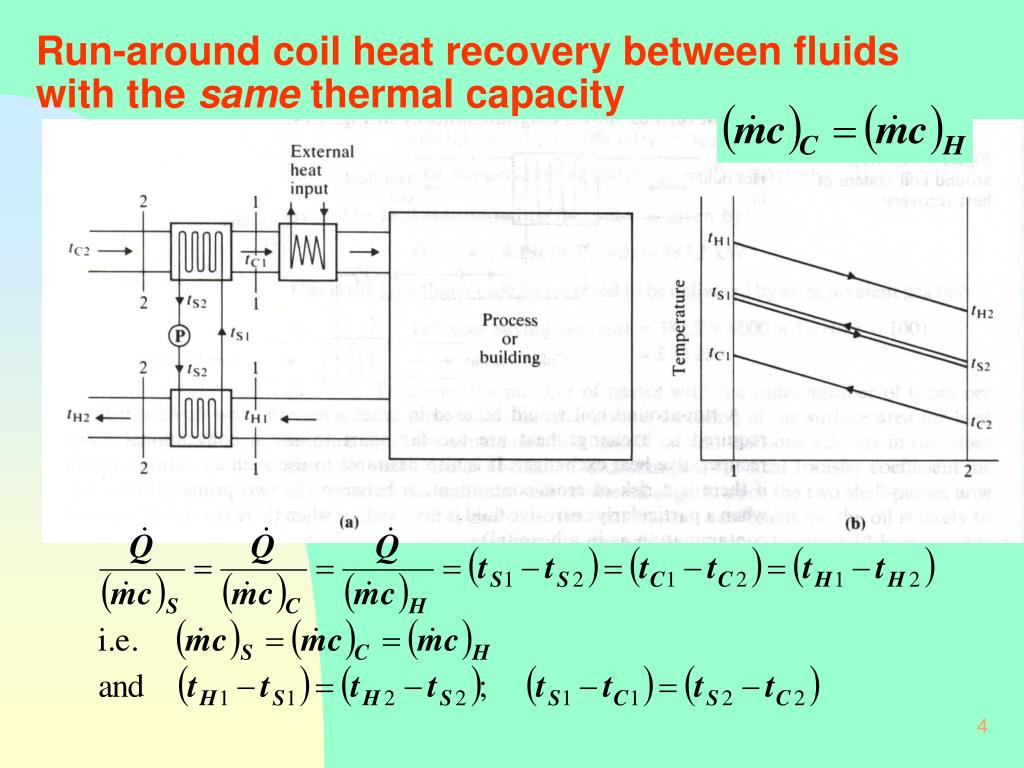

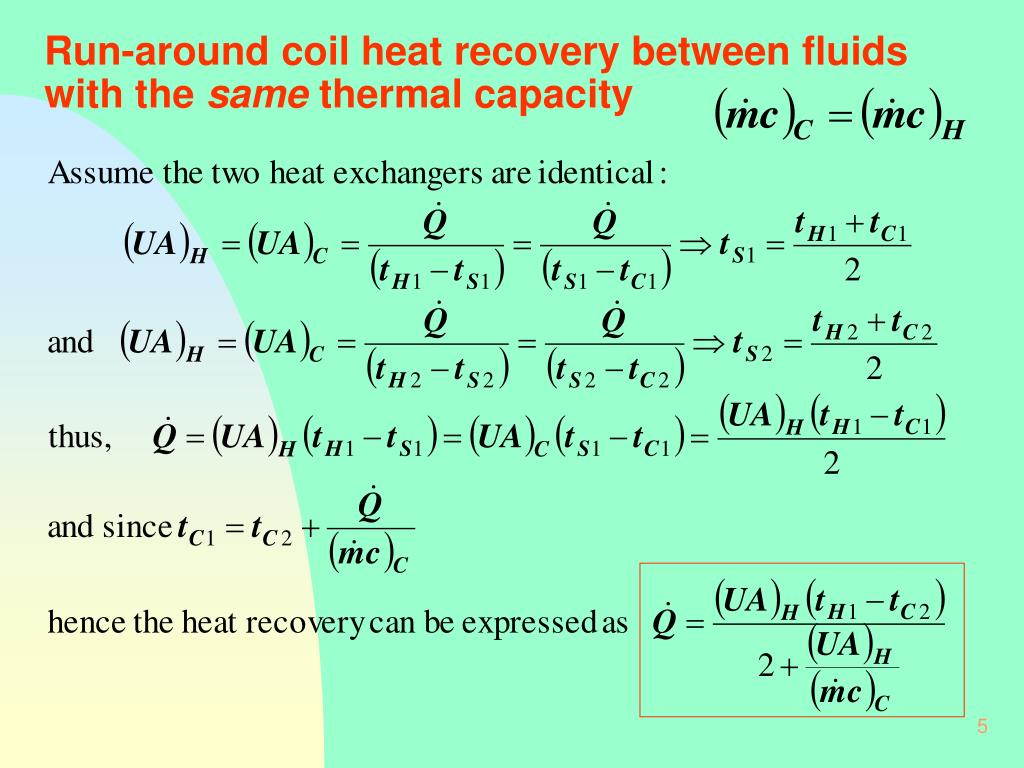

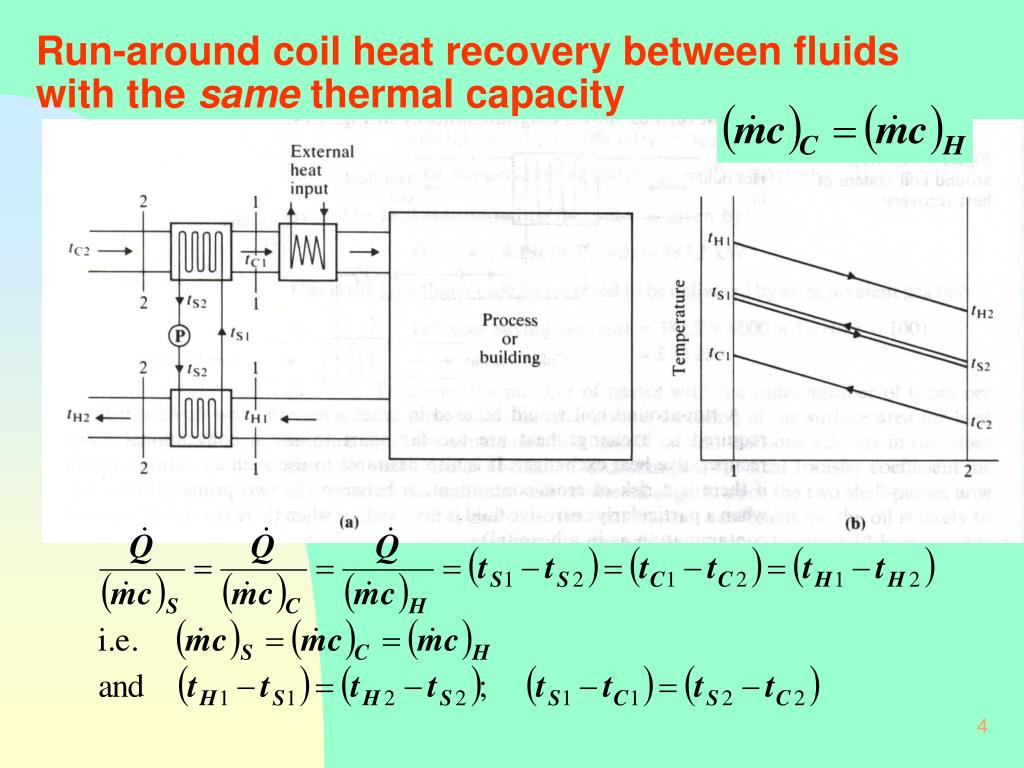

What is a run-around heat recovery coil? A run-around coil heat recovery system consists of two separate heat exchangers connected by a closed loop of piping. One heat exchanger is installed in the hot fluid stream, and the other is in the cold fluid stream. A run-around system is a waste energy recovery system that uses coils in the exhaust airstream to transfer energy back to the supply air via another set of coils. The heat is transferred between the coils by interconnecting piping and a pump/control package. Unique Approach to High-Efficiency Laboratory-Exhaust Energy Recovery | HPAC Engineering The team incorporated a high-performance networked run-around heat-recovery-coil loop system along with indirect adiabatic/evaporative cooling of exhaust air. A run around coil loop simply moves heat from one air stream to another via two heat exchangers and a heat transfer medium, usually water or glycol. A pump is required to move the medium through the system.

PPT Runaround Coil Systems Definition of RunAround Coil Systems Design Factors Examples

Run Around Coil Pump Sets Centrifugal type, single stage end suction, with an enclosed radial impeller, of stainless steel construction, fitted with a mechanical seal and close coupled to a three phase electric motor (Single phase motors available on request). Motor Standard metric frame, T.E.F.C., IP 55, 400 volt, 3 phase, 50 cycles. Brochure: Corporate Datasheet: Energy Recovery FIND A REPRESENTATIVE to help design a product that's right for your project. Custom air handlers with diverse energy recovery options including enthalpy wheels, sensible or flat plate heat exchangers, heat pipes, and run-around coils A run around coil system consists of at least one heat exchanger in the supply and extract air flow which are connected to one another by a hydraulic circuit. The heat transfer fluid is usually a mix of glycol and water. Investment with a future - up to 80% heat recovery A basic run-around energy recovery system consists of fluid-to-air heat exchangers ('coils') in the supply air handler and the exhaust air handler, and a pump to transport the fluid through the coils and interconnecting piping.

PPT Runaround Coil Systems Definition of RunAround Coil Systems Design Factors Examples

1 year. Collects information on user preferences and interaction with web-campaign content which is used on CRM-campaign-platforms used by website owners for promoting events or products. test_cookie. 15 minutes. The test_cookie is set by doubleclick.net and is used to determine if the user's browser supports cookies. This is 43rd HVAC SYSTEM DESIGN Tutorial for beginners. In this tutorial, we will:- Introduce the concept of run around heat recovery coil and its installati.

Run-around coils and heat pipes can both be used to recover heat from contaminated airstreams because both allow for completely separate airstreams without the possibility of any cross-contamination. A run-around coil uses two coils connected by pipe with a pump to circulate a heat-transfer fluid, which is often a glycol brine in cold climates.. A run-around coil system comprises two or more multi-row finned tube coils connected to each other by a pumped pipework circuit. The pipework is charged with a heat exchange fluid, water, which picks up heat from the exhaust air coil and gives up heat to the supply air coil before returning again.

PPT Runaround Coil Systems Definition of RunAround Coil Systems Design Factors Examples

Energy Recovery Solutions Econet Premium is FläktGroup's reliable and well proven intelligent run around coil recovery system with up to 80% heat recovery efficiency. Safe system - no risk for transfer of bacteria or odour from exhaust to supply air High heat recovery efficiency The run-around coil loop is a preferred method of recovering energy from hazardous lab exhaust because separation is maintained between the exhaust and supply airstreams, eliminating the concern of cross-contamination. The exhaust coil has a corrosion-resistant coating that ensures safe and consistent recovery of sensible energy.