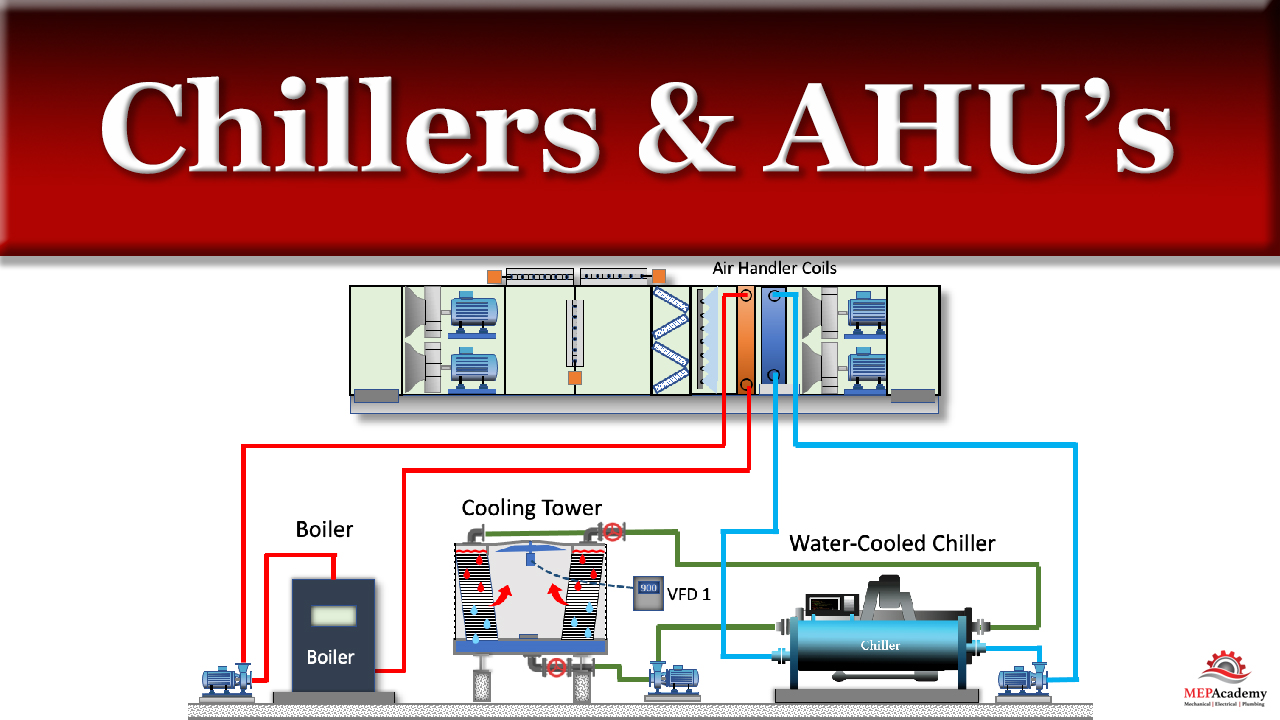

13 How Air Cooled Chillers work In this article we will be looking at how air cooled chillers work. Air cooled chillers are very common, especially in small to medium size commercial and office type buildings. They are usually located externally, either up on the roof or at ground level. Diagram B Like with water-cooled chillers, the process begins with the primary return bringing warm water to the chiller. Heat is transferred in the evaporator to the refrigerant, and the water runs through the primary supply to the cooled space.

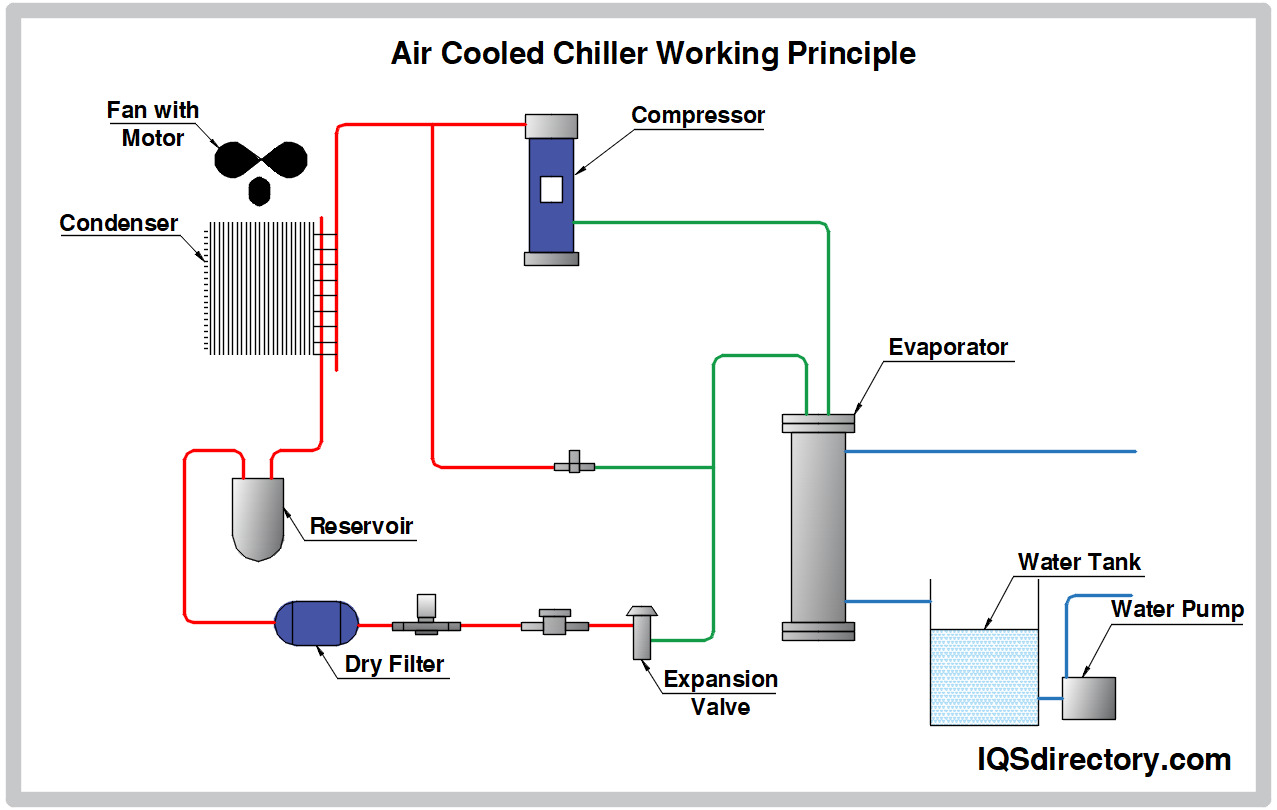

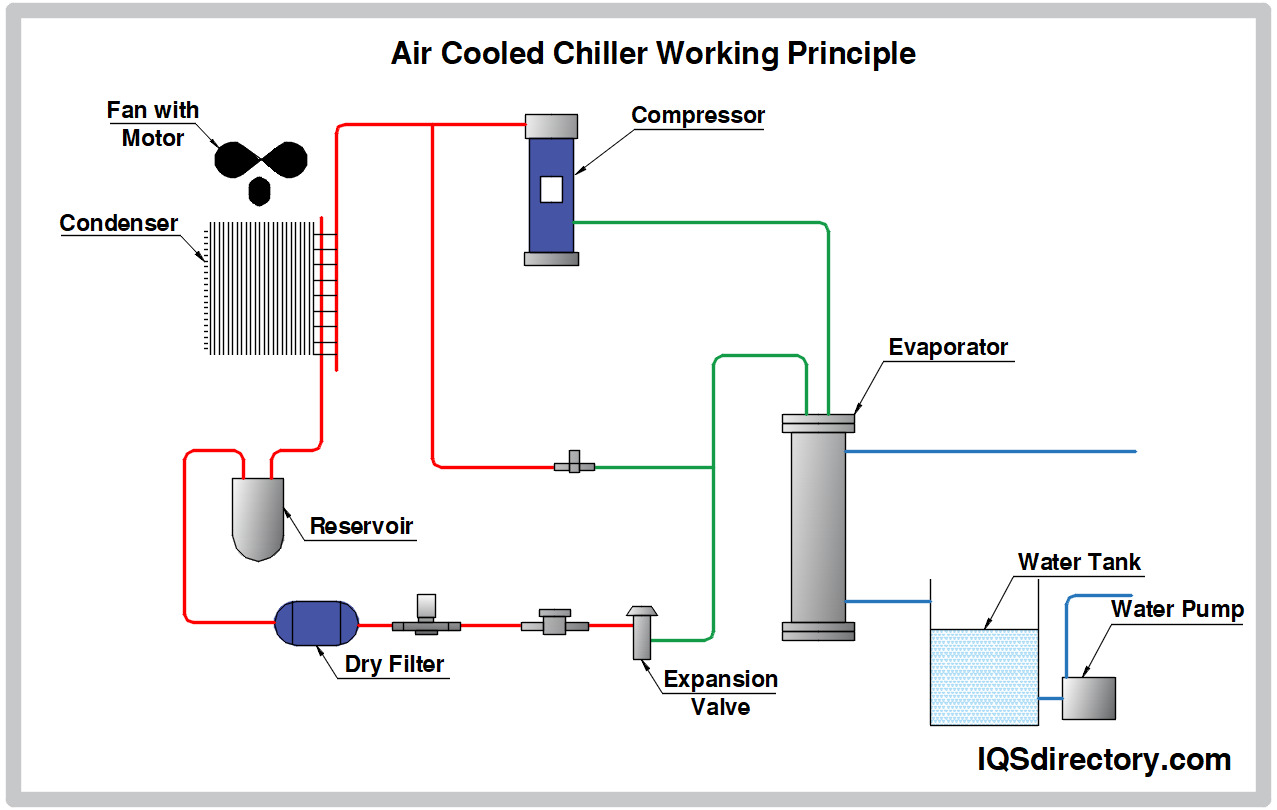

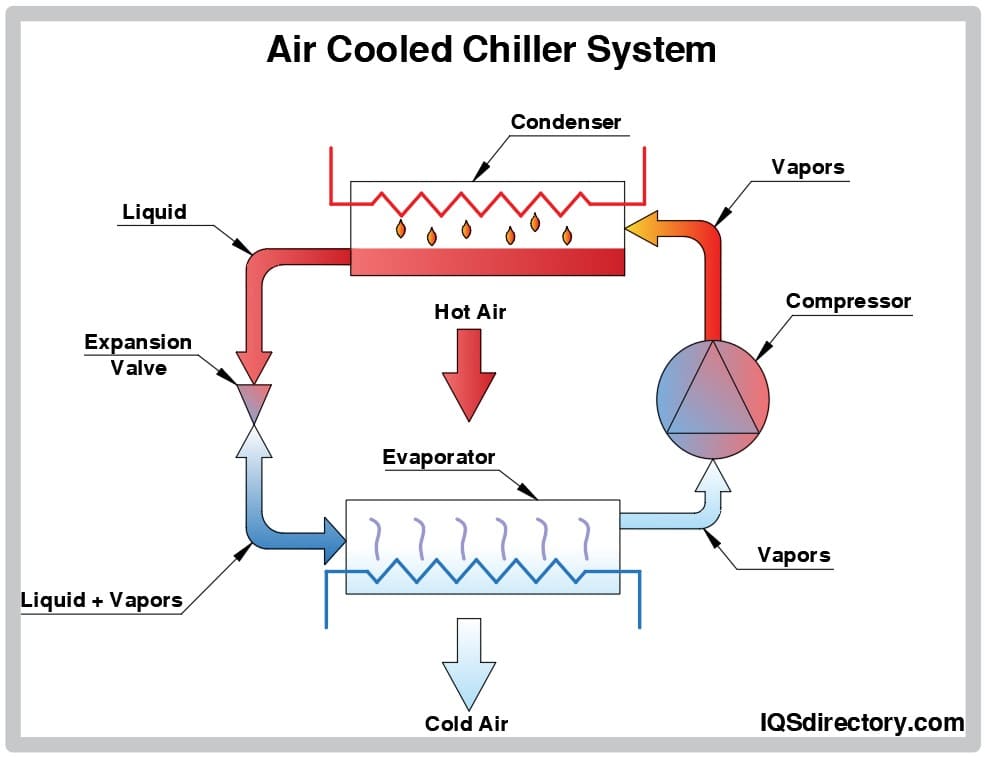

Air Cooled Chiller Diagram

Air-Cooled Scroll Chillers Model CGAM 20 to 130 Tons — Made in USA Installation, Operation, and Maintenance March 2021CG-SVX17M-EN Model:CGAM SAFETY WARNING Only qualified personnel should install and service the eq uipment. This video guides you through the basic operation of a chiller, making use of animations, illustrations, 3D models and real world photographs to help build y. This is the maintenance guide for the YORK® YLAA Air-Cooled Scroll Chiller, a high-efficiency and environmentally friendly cooling system that can operate in various conditions. The guide provides detailed instructions on how to install, operate, troubleshoot and service the chiller, as well as the wiring and control diagrams. RT = Rotary chiller Digit 3 - Unit Type A= Air-cooled Digit 4 - Development Sequence C = Development sequence Digits 5, 6 and 7 - Nominal Capacity 120 = 120 Nominal tons 130 = 130 Nominal tons 140 = 140 Nominal tons 155 = 155 Nominal tons 170 = 170 Nominal tons 185 = 185 Nominal tons 200 = 200 Nominal tons 225 = 225 Nominal tons

How an air cooled chiller works refrigerant The Engineering Mindset

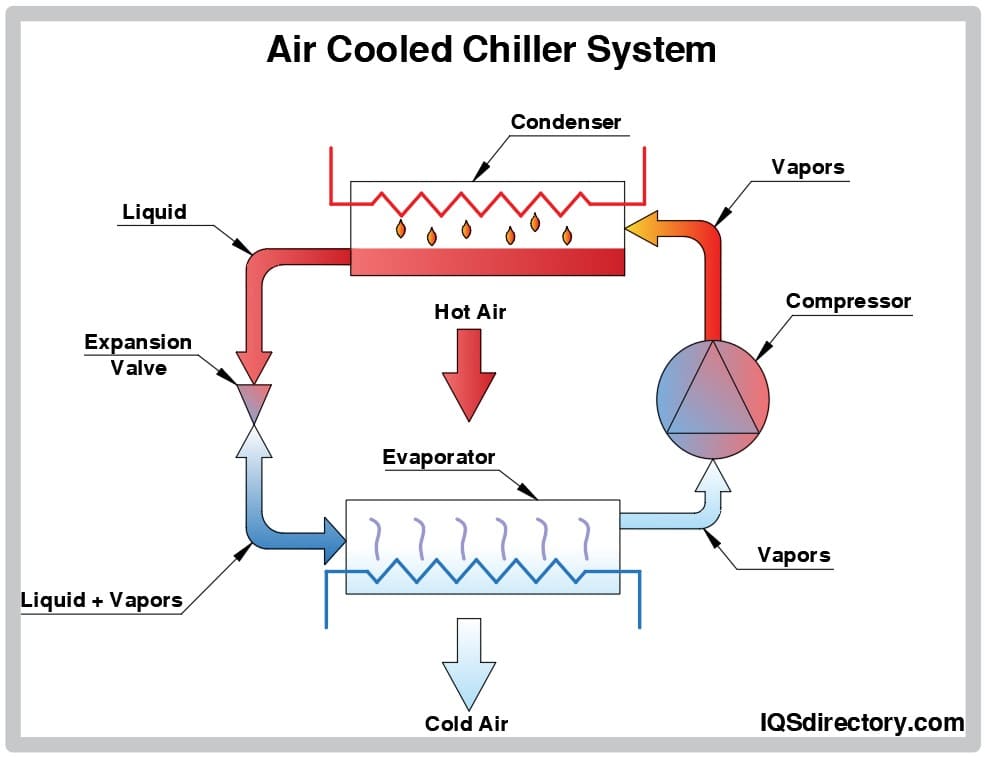

Air-Cooled Scroll Chillers Model CGAM with Symbio™ Controls 20 to 130 Nominal Tons (60 Hz) ©2023 Trane CG-SVX063A-EN Introduction. • Drawing numbers for unit wiring diagrams Model Number Coding System The model numbers are composed of numbers and letter which represent features of the equipment. Air cooled chillers are types of chillers that rely on the use of fans to reject heat outside the building rather than relying on cooling towers. Air cooled chillers consist of four major parts: a compressor, an evaporator, a condenser, and an expansion valve. WIRING DIAGRAM AND DIMENSIONAL DRAWINGS MUST BE CONSIDERED ESSENTIAL PARTS OF THIS MANUAL In the case of discrepancy between this manual and the wiring diagram or the dimensional diagram, the latter two. EWT: Air cooled chiller, cooling only with heat recovery Refrigerant D: R-134a P: R-407C Q: R-410A Capacity class in kW (cooling) Always 3. Air-cooled chillers are generally the major electricity consumers in air-conditioned buildings in the subtropical climate. To improve the energy efficiency of the air-cooled chillers.

Air Cooled Chiller Manufacturers Suppliers

The air cooled chiller diagram is a visual representation of the components and processes involved in the functioning of an air cooled chiller system. This diagram helps to understand how the system works and how each component interacts with the others. Paul Evans. -. Jun 7, 2019. 1. Air cooled chiller design data. In this tutorial, we're going to be taking a look at air cooled chillers to find out how they work in a more advanced way. We're going to be taking a look at the refrigerant this time and the pressures, temperature, enthalpy, entropy, flow rates and heat transfer.

Air-cooled chillers are refrigeration systems used in both commercial and industrial facilities to cool fluids and/or dehumidify air. They are used in a wide variety of settings including hotels, corporate events, restaurants, sporting events, large-scale construction, industrial and manufacturing plants, and so forth. The air-cooled condenser is a heat exchanger where the process heat absorbed by the refrigerant is given off to the air around it. As heat is given off by the high temperature high pressure vapor, its temperature falls until the vapor condenses to a liquid. A centrifugal blower or motor driven fans generate airflow across the condenser.

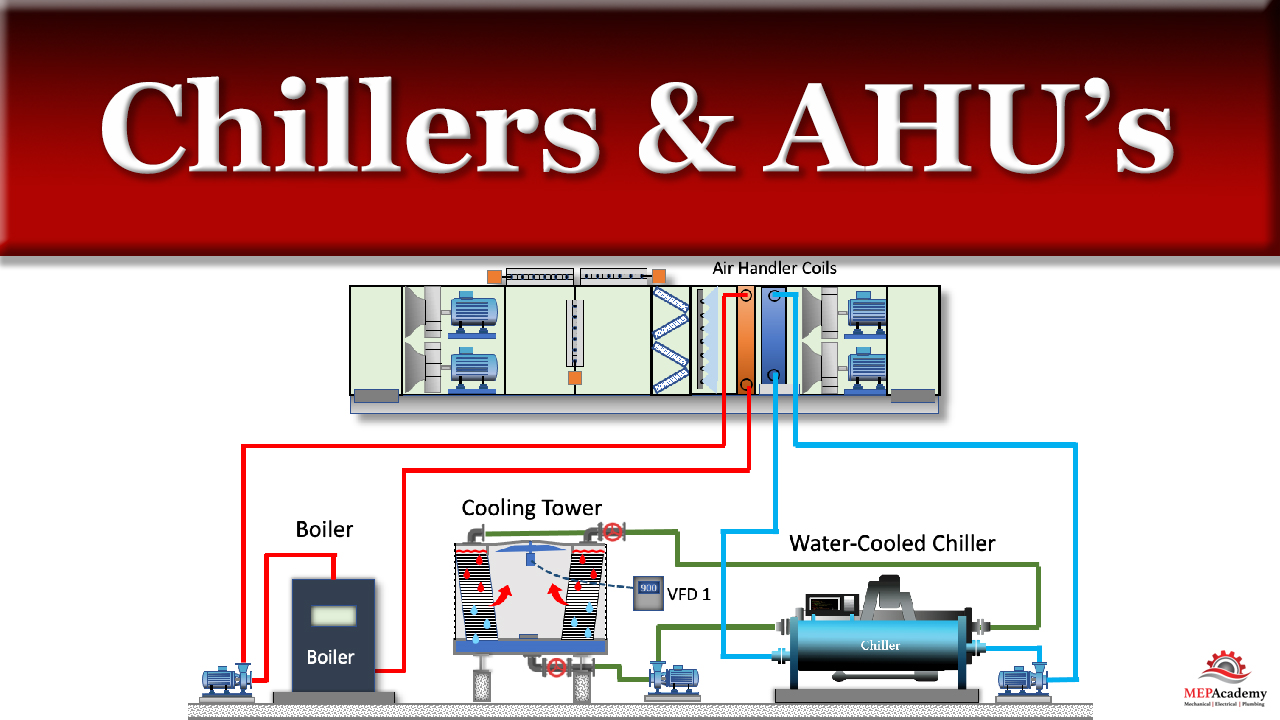

Top 111 + How chillers work animation

• 14°F+ cooling-tower range to save energy and cost • 50 percent or better cooling tower water turndown for efficient staging, waterside free cooling support and code compliance • Variable speed condenser pumps to reduce or eliminate balancing valves • Makeup water from condensate reclaim An air-cooled chiller uses fans to reject the heat outdoors, while a water-cooled chiller will require a cooling tower that sends water to the chiller to absorb the unwanted heat, and then eject that heat through the tower process. Roof mounted Air-cooled chiller serving horizontal fan coils