Step 1 - Malt Milling To make beer, sugar is needed, and we get sugar from sprouted barley. The fermentable sugar in the malt is contained in the outer shell of the inner core, which is starch at this time. Now we need to open the shell to expose the starch for transformation. 06/22/2023 Malt Brewing begins with raw barley, wheat, oats or rye that has germinated in a malt house. The grain is then dried in a kiln and sometimes roasted, a process that usually takes place in a separate location from the brewery.

Brewing Process Smoky Mountain Brewery

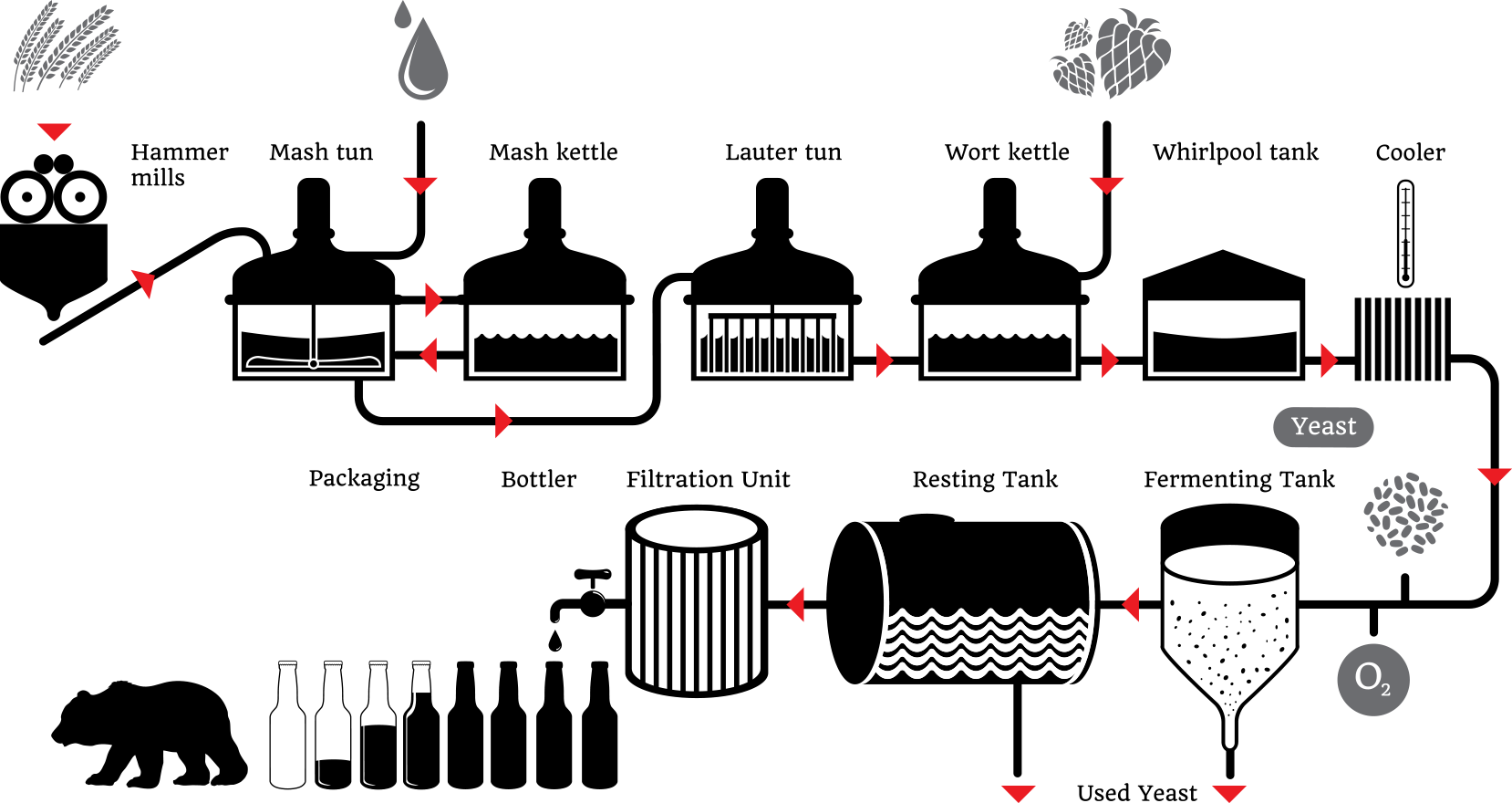

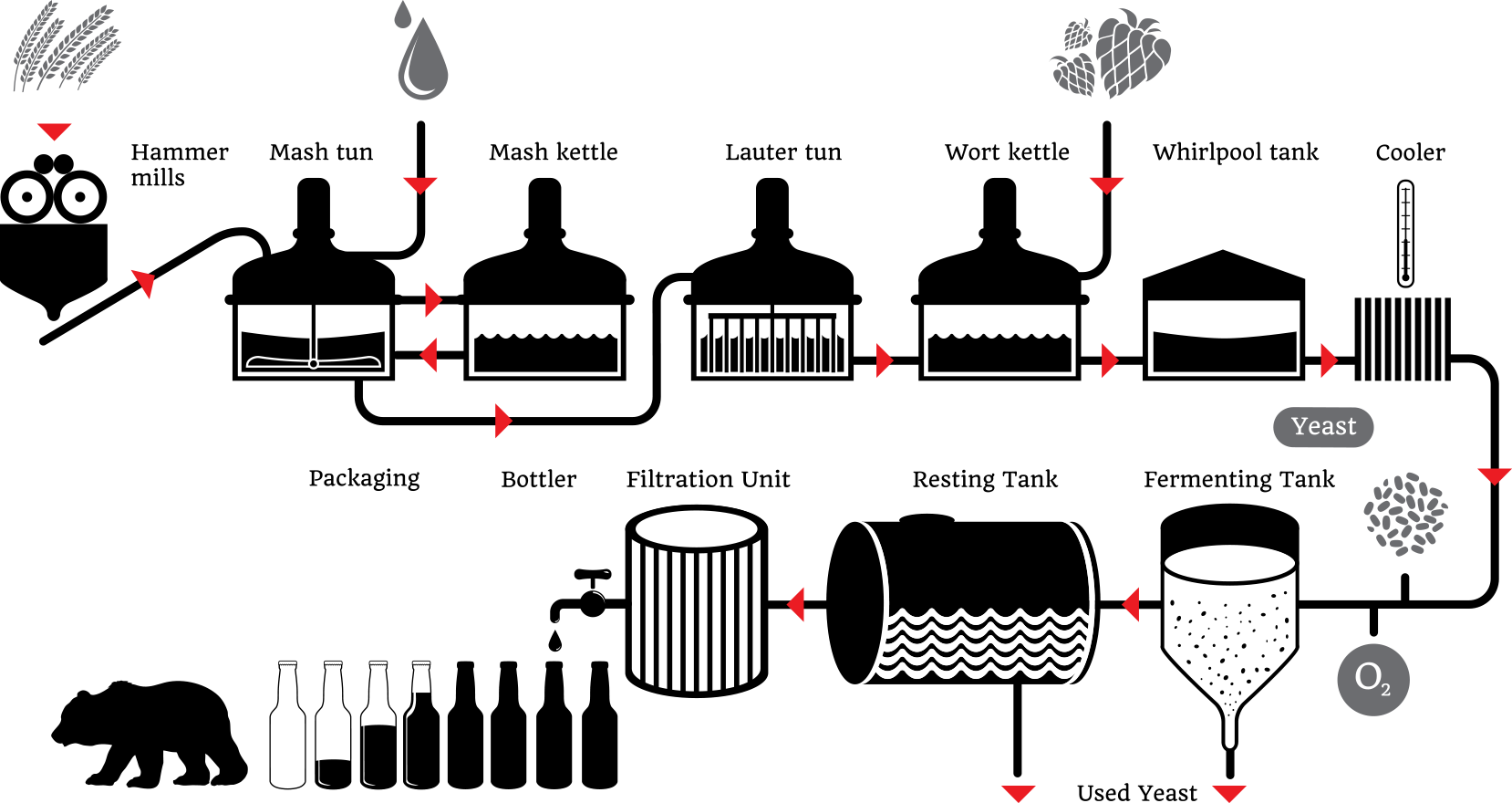

Grain Beer production begins with malting grains. Barley is the most common grain in beer, but some recipes include wheat, corn, and rice. The beer you brew by adding any grains is well-known as all-grain beer. You can store whole grains for months before brewing. Once you crush or mill them, you need to use them as soon as possible. Overview of the Brewing Process. By Brewpubs Committee. Brewers Association. August 14, 2020. Your staff should be familiar with the basics of the brewing process. This guide includes a brief description of each step. Beer brewing is essentially a biotechnological process, meaning the action of brewing and the making of beer depend on numerous enzymes and their reactions; microorganisms, including yeast, release these enzymes. The primary ingredients of beer are water, malted cereals (mainly barley), hops, and yeast. 1. Cleaning & Sanitizing Once you have all of the necessary equipment, the first step isn't actually brewing at all. First, you'll need to thoroughly clean and sanitize ALL of your equipment. This step is crucial. Do not take any shortcuts here.

The Brewing Process Brewing process, Brewing, Craft beer tasting

The Basic Process Equipment Crushed Grains All Grain Brew Steps 1. Heat Strike Water 2. Doughing In 3. Mash (Saccharification Rest) 4. Mashout (Raising the Grain Bed to 168°F) 5. Vorlauf/Recirculate 6. Sparging (Continuous Sparge or Batch Sparge) Calculating Sparge Water Simple Batch Sparge (Double Batch Sparge) Fly Or Continuous Sparging 7. This is a detailed, step-by-step guide to the beer-making process. It covers wholegrain brewing and brewing with a malt extract. This post is part of a series of posts on the beer-making process. See Homebrewing 101 for detailed information on the equipment, ingredients, sanitation, and recipes. Step 1: Malting. The first main step in the brewing process is known as the malting phase. Every beer contains some type of grain. Barley is the most popular, but many brewers use wheat and rye as a substitute. These grains are dried out and cracked in a heating process. 1 449 Post Recommended Templates This Brewing process diagram depicts malting, milling, mashing, extract separation, hop addition and boiling, removal of hops and precipitates, cooling and aeration, fermentation, yeast separation from young beer, aging, maturing, and packaging.

The Brewing Process Beer Brewing Process, Home Brewing Beer, Beer Tanks

The brewing process can be broken down into four simplified steps: Mashing, separation, boiling, and fermentation. The four beer ingredients are brought together in each of these steps to create an enormous range of beer styles. The darkest stout and the lightest pilsner are made from the same four ingredients: Water, malt (or other grains. Beer is an alcoholic beverage produced by extracting raw materials with water, boiling (usually with hops), and fermenting. In some countries beer is defined by law—as in Germany. Brewing in the 21st century is a large-scale industry. Learn about the history, types, and brewing process of beer.

Steps in the brewing process include malting, milling, mashing, lautering, boiling, fermenting, conditioning, filtering, and packaging. There are three main fermentation methods: warm, cool and spontaneous. Fermentation may take place in an open or closed fermenting vessel; a secondary fermentation may also occur in the cask or bottle. Milling To make beer we need sugar, we get it from malted barley. The fermentable sugars needed are contained inside the husk of the kernel. It's actually starch at this point. We need to crack open this husk to expose the starch for conversion. When looking to order a mill for brewing, it's best to get one with adjustable rollers.

Image result for brew process diagram uk Brewing process, Brewing

The brewing process diagram is a great way to see how beer is made and to get an understanding of the different steps involved. It's also a handy tool for those who are new to brewing. If you're new to brewing, or just want to get a quick understanding of the brewing process, then a brewing process diagram is a great place to start. Beer is an incredibly popular drink, and it's fascinating to learn about the steps that go into making it. Did you know that after tea and coffee, beer is th.