Looking for Cnc Rack And Pinion? We have almost everything on eBay. No matter what you love, you'll find it here. Search Cnc Rack And Pinion and more. October 28, 2022 4 min read CNC machines are fairly complex, and the CNC rack and pinion system helps them to operate. But what are gear racks and pinions? In this article, we'll take a closer look at: Rack and pinion design What a rack and pinion is What racks and pinions do How gear racks and pinions work

Sjuul CNC Quick Release Rack and Pinion system YouTube

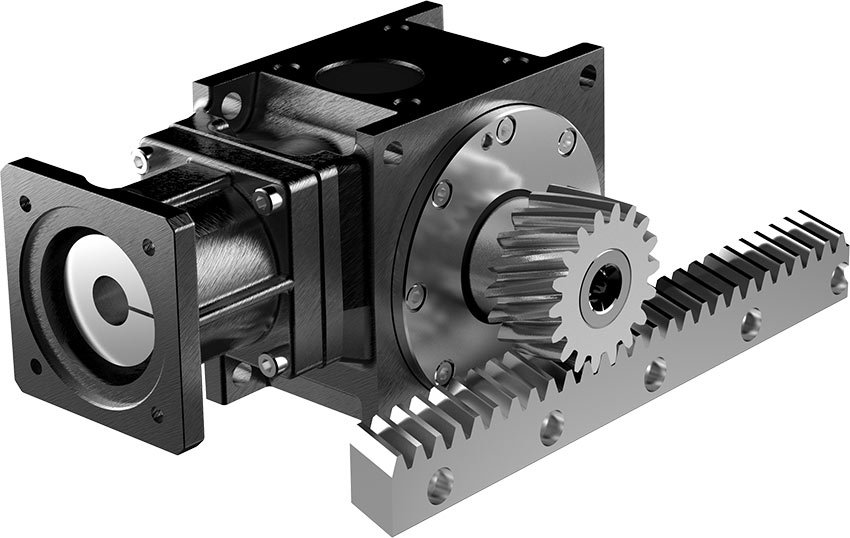

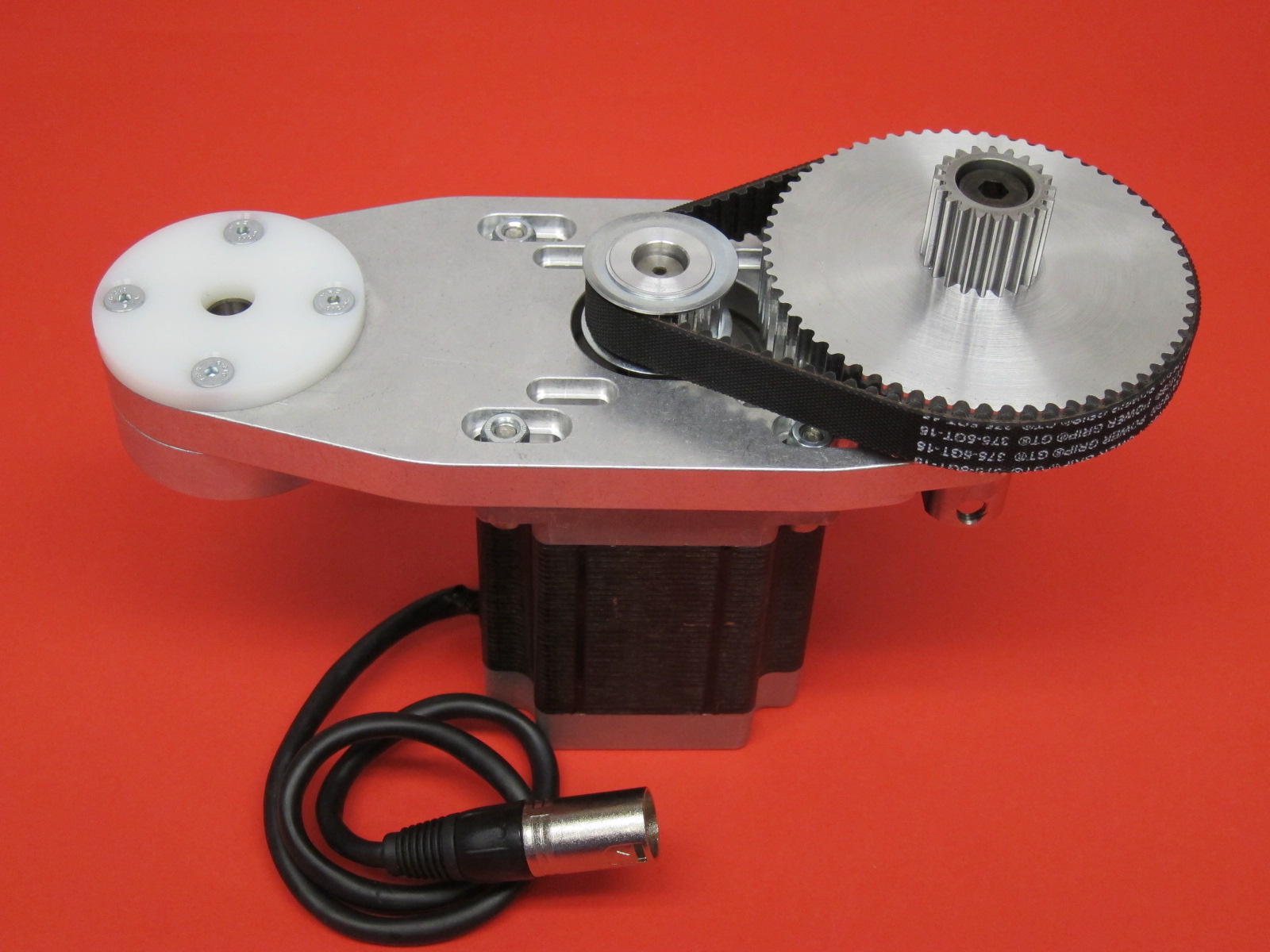

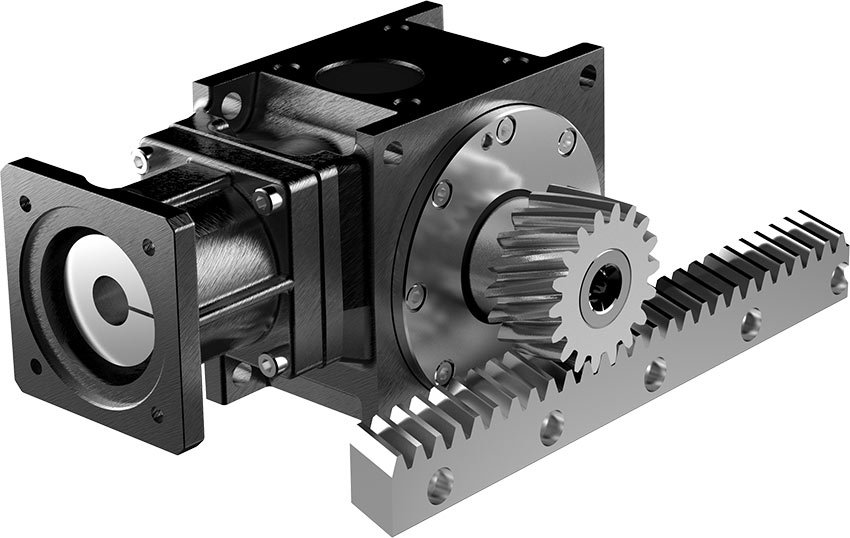

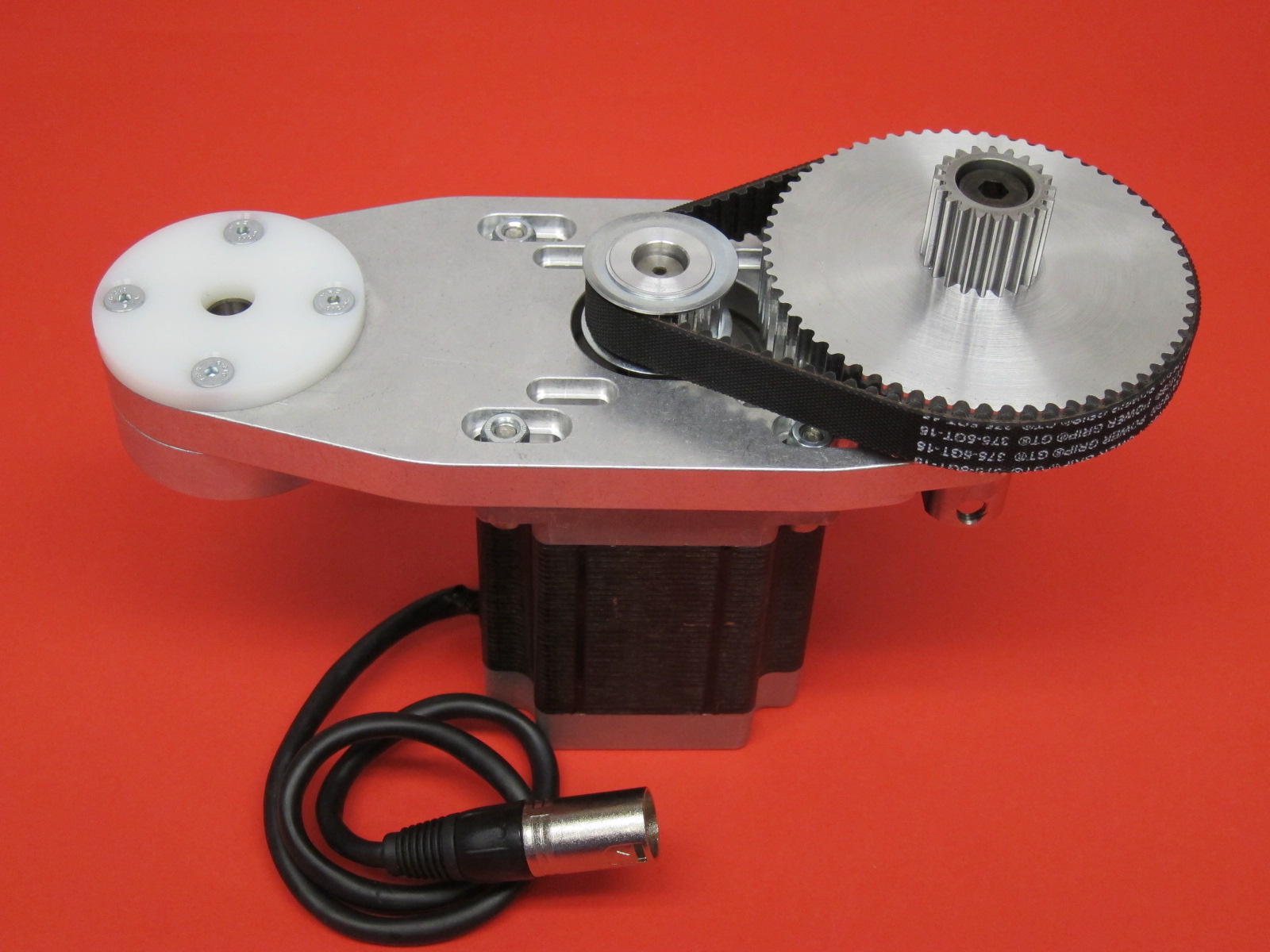

rack and pinion is a type of that comprises a circular ) engaging a linear gear (the ), which operate to translate rotational motion into linear motion. A Rack and Pinion Drive… They're most commonly used on cnc machines such as CNC Plasma Tables and CNC Routers where they are a good match for the long travels and other performance needs. The rack is a set of teeth that bolts onto the side of the frame of the CNC machine. The pinion is a cog or gear that meshes with the rack. As the pinion turns, the machine moves. One of the key shortcomings of rack and pinion machines is that the fit between the rack and the pinion cant be perfectly tight or the machine will lock up. Rack and Pinion will not allow for even cut forces because the CNC router head will apply additional cut forces to the closest gear and motor forcing the other motor to adapt its speeds to keep the gantry straight as it applies more torque into a gear many times not much bigger than a wedding ring. What's Included (1) Motor mount pivot plate (4) 10-32 x 5/8" socket head cap screw (for motor mounting) (4) 10-32 hex nut (for motor mounting) (1) Pivot shoulder bolt, with precision shim (1) NEMA 23 R&P Drive Spindle with mounting hardware (1) NEMA 23 R&P Motor Pulley with 3/8" bore (optional 1/4" bore pulley available) (1) NEMA 23 R&P Drive Belt

CDA Rack & pinion mechanisms

Our Standard Rack and Pinion Drive system is perfect for larger format machines, 4' x 8', 5' x 5', and larger. This NEMA 34 R&P Drive system features 4 times the torque capacity of our NEMA 23 R&P Drive system by using larger series belts and pulleys. Standard CNC Rack and Pinion components from Avid CNC. 3D Printing & CAD. AUTOMATION & IIOT. Rack-and-pinion sets deliver precise motion over unlimited lengths without the complexity of motors and ball screws. Rack and pinion drives are an age-old mechanism widely used for converting rotary motion into linear motion.. CNC routers, pick-and-place robots, traveling gantries, material handling.

1000+ images about CNC on Pinterest Cnc machine, Rocking chairs and

PRO Rack and Pinion Drive Assembly Instructions v2020Q4.2 Tools List Required tools for assembly and installation of PRO Rack & Pinion Drives: Metric Allen Wrenches: -3mm, 4mm, 5mm, 6mm Imperial Allen Wrenches: - 3/32", 1/4" 16mm Combination Wrench Standard (Flat Tip) Screwdriver Tape Measure Section 1: PRO R&P Drive Assembly Section Note For example, of the over 700 active TITAN ® CNC Routers in production throughout North America, less than 1% of them have needed replacements for their rack and pinion systems. In addition, rack and pinion systems allow for faster movements, optimized for running high speed tooling to increase your machine efficiency.

Standard Rack and Pinion Drive Assembly & Installation Instructions. Remove tape on motor shaft. Loosen motor pulley set screws. Install motor pulley on motor shaft as indicated. Ensure keyway is fully seated in slot on motor shaft to allow easy installation of the motor pulley. Position motor pulley to dimension shown. Standard CNC Machine Assembly Instructions 4. Rack and Pinion Drive Installation . Initializing search . Include in search: CRP4848 Assembly Instructions. Other current instructions. All archived instructions. Frequently asked questions.. 4.2 Rack and Pinion Assembly (NEMA 34).

Everyday low prices New things that make life easy MOD 1.0 and 1.5

Our PRO Rack and Pinion Drives offer tighter interfaces and higher accuracy than our standard line, with the following features: Ball bearing pivot interface. Super-oilite bushing and matched precision ground spindle shaft. High resolution 3.2:1 belt drive reduction for NEMA 34 motors motors. The rack product range consists of metric pitches from module 1.0 to 16.0, with linear force capacities of up to 92,000 lb. Rack styles include helical, straight (spur), integrated and round. Rack lengths up to 3.00 meters are available standard, with unlimited travels lengths possible by mounting segments end-to-end.