Tie rod style hydraulic cylinders use high strength threaded steel rods to hold the two end caps to the cylinder barrel.This method of construction is most often seen in industrial factory applications. Small bore cylinders usually have 4 tie rods, while large bore cylinders may require as many as 16 or 20 tie rods in order to retain the end caps under the tremendous forces produced. How does the hydraulic cylinder work? A hydraulic cylinder has the following parts: piston, rod, seals, wipers, barrel. Read more http://www.hydraulic-calcul.

HYDRAULIC SYSTEM FOR BEGINNERS Mechanical Engineering Professionals

Guide to Understanding Hydraulic Cylinder Parts: Names & Diagram. by Swap. A hydraulic cylinder is a mechanical actuator that gives a unidirectional motion through the force of the hydraulic liquid. It is also referred to as a linear hydraulic motor. It has a wide area of applications, ranging from the construction industry to mechanical machines. Hydraulic Cylinder Base/Gland. Also called the rod end, the hydraulic cylinder base is the visible opening that a cylinder rod connects to. The gland is attached with tie rods, bolts, welding, or threading. Hydraulic cylinders incorporating a tie rod utilize high-strength steel rods that are threaded for holding end caps to the barrel. A hydraulic cylinder schematic diagram provides a visual representation of the different components and fluid flow paths within a hydraulic cylinder system. By studying these diagrams, engineers and technicians can gain valuable insights into the functionality and performance of hydraulic cylinders. Cylinders. Cylinders are linear actuators that can produce large forces in small volumes. There are generally three types represented in a schematic. A single acting cylinder is one where hydraulic oil is only supplied to one side (usually the bore) and either gravity or springs make it return. A bottle jack is a good example of this.

How to Rebuild a Hydraulic Cylinder Intella Parts Company, LLC

The hydraulic cylinders on this excavator operate the machine's linkages. Hydraulic cylinders in a hot press of a particle board machine. A hydraulic cylinder (also called a linear hydraulic motor) is a mechanical actuator that is used to give a unidirectional force through a unidirectional stroke. It has many applications, notably in construction equipment (engineering vehicles. Hydraulic cylinder designers need to think about the scale and size of a hydraulic cylinder. A cylinder that has an excessive reach poses the risk of buckling - meaning that the rod and barrel have to be engineered to be larger. However, this increase in area would have a bigger force, potentially over engineering the fabrication and making. A hydraulic cylinder has eight basic components; the clevis, gland, port(s), barrel, rod, piston, the end cap, and the seal. When combined, these parts allow the hydraulic cylinder to pressurise fluid that mobilises a piston to generate power for a machine. Draw a pictorial diagram of a double acting hydraulic cylinder. Identify the barrel, piston, rod, cap end plate, rod end plate, rod wiper, cap end port, and rod end port. NOTE: the rod end is often called the "head" end and the cap end is often called the "blind" end. Draw the schematic symbol for a double acting hydraulic cylinder.

Peninsular Cylinder Co. cylinder repair, hydraulic cylinder repair

The term cylinder is commonly used to describe a device that gives linear force output and movement. A cylinder may also be referred to as a linear actuator. Cylinders are broken down into two main categories: pneu-matic and hydraulic. Pneumatic cylinders can be operated by several types of gases; however, compressed air is by far the most common. Figure 12-2: Hydraulic system pictorial diagram. Cutaway Diagrams. Cutaway diagrams (Figure 12-3) show the internal working parts of all fluid power components in a system. The diagrams include controls and actuating mechanisms and all interconnecting piping.. Two hydraulic cylinders are attached to each JBD panel shaft by crank assemblies.

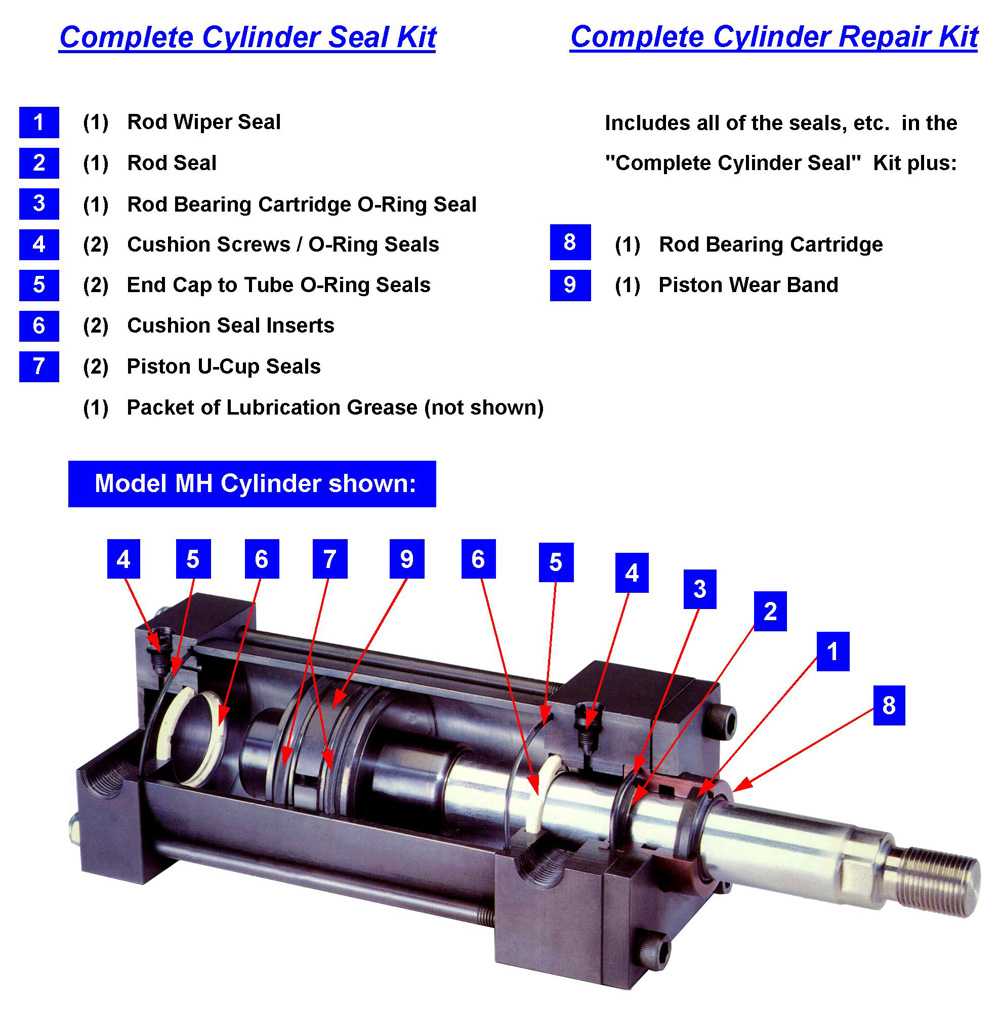

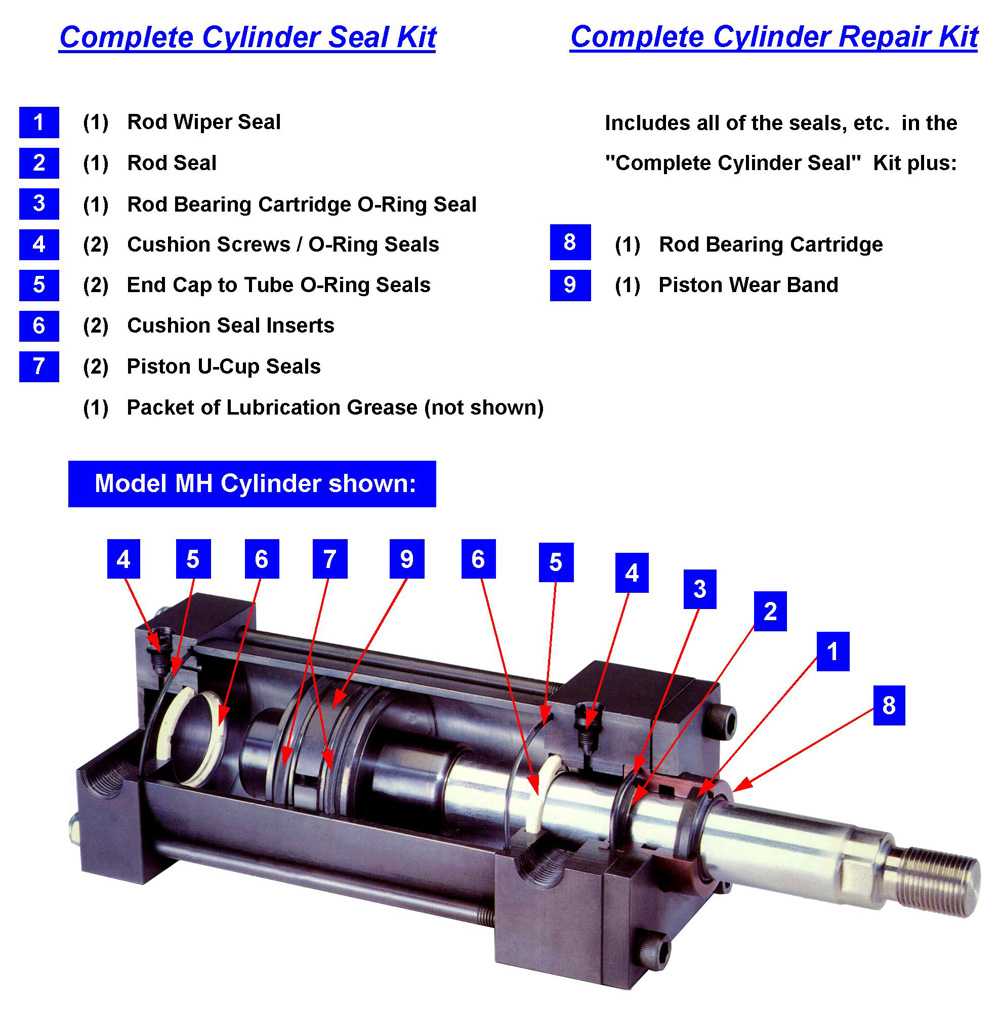

Cylinder Working a Rotating Lever: A cylinder working a hinged lever can exert its maximum force on the lever only when the lever axis and cylinder axis are at right angles. When Angle "A" is greater or less than a right angle, only part of the cylinder force is effective on the lever. The cylinder force is found by multiplying the full Series 3H Large Bore Hydraulic Cylinders Parts Identification 52-53 Seal Kits 53 Series 3H 7" & 8" Bore Hydraulic Cylinders Parts Identification and Maintenance Instructions 54 & 55 Series HMI Cylinders Parts Identification 56-57 Seal Kits and Replacement Parts 57 Series HD-HDC Automotive Hydraulic Cylinders Service Assembly Kits 58 Seal Kits.

The Function of Seals In a Hydraulic Cylinder หน้าที่ของซีลในกระบอกไฮดรอลิก

Hydraulic symbols are a standard designed to provide a clear representation of how each hydraulic component functions in a hydraulic system. Hydraulics engineers regularly encounter these diagrams, but these symbols can be daunting to interpret if you have limited experience with schematics and the fluid power industry. Cylinders are mechanisms connected to the slide which help in moving the slide up and down. On the other side, the cylinders are mounted to the frame at the top of the system. Cylinders are one of the major components of the hydraulic system and are needed to build a hydraulic press.