Making an EPIC Handcrafted BOOK PRESS Darbin Orvar 357K subscribers Subscribe Subscribed 3K 91K views 3 years ago USA Building a #BookPress with mostly handtools in white oak with halfblind. Watch more videos - http://bit.ly/SeaLemonDIYChannelSubscribe - http://bit.ly/SeaLemonDIYsubClick for more info below ↓ UPDATE: More DIY book press methods.

3 DIY Book Press Designs Worth Checking Out Man Made DIY Crafts for

This particular book press was designed to fit the maximum number of books simultaneously, two stacks at a time. If you don't need or want to flatten quite so many books, you can easily truncate the length of the planks and use only four bolts. Materials. Two (2) lengths of 2″ x 8″ oak board, about 3.5′ to 4′ in length (approx $25-40) Making an EPIC Handcrafted BOOK PRESS Darbin Orvar Making an Inexpensive Finishing Press DIY Book Press on the Cheap! Wood Tool: Superior Way To Cut Paper // Book Plough Build Building an. Book Press From Scratch By bangnhipham in Workshop Woodworking 52,814 263 18 Featured Download Favorite This build was developed out of a desire for affordable college textbooks coupled with a willingness to learn a new skill and apply it to our needs. DIY Large Format Book Press Puts On The Pressure 12 Comments by: Tom Nardi March 3, 2020 For those in the audience who aren't well versed in wrangling dead trees, a large press with a lot of.

DIY book press Book binder, Book binding, Bookbinding tools

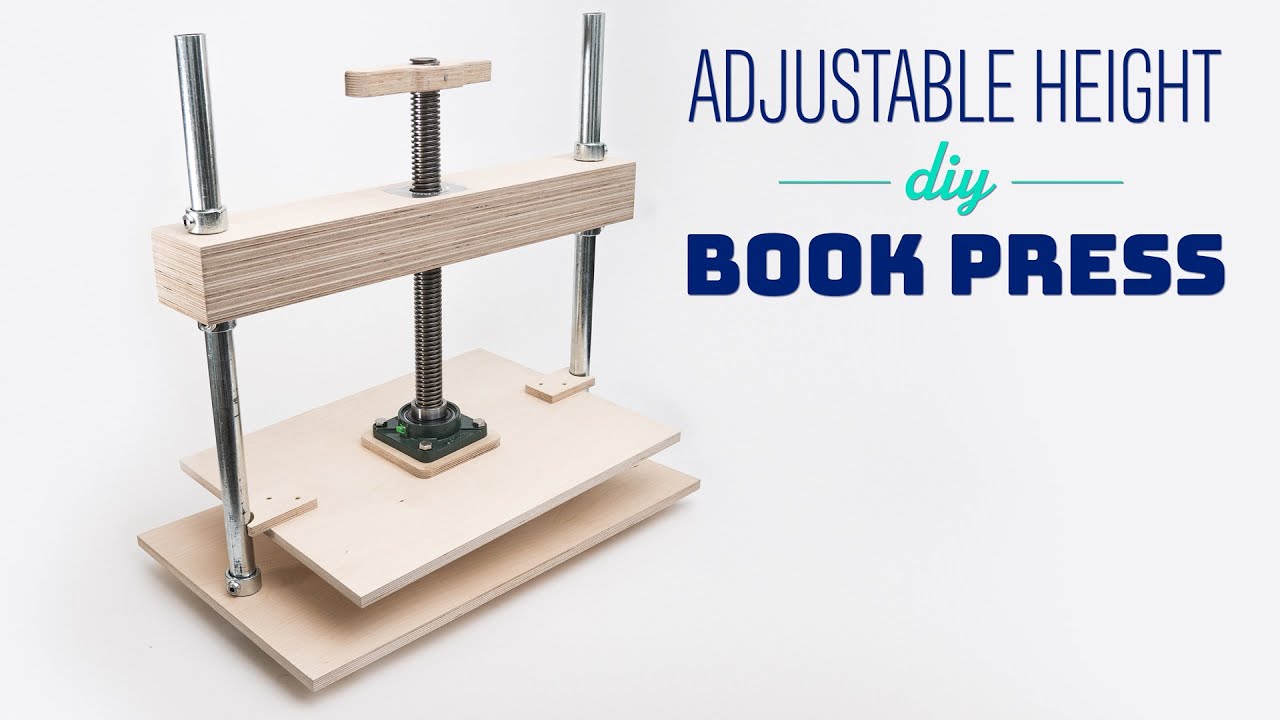

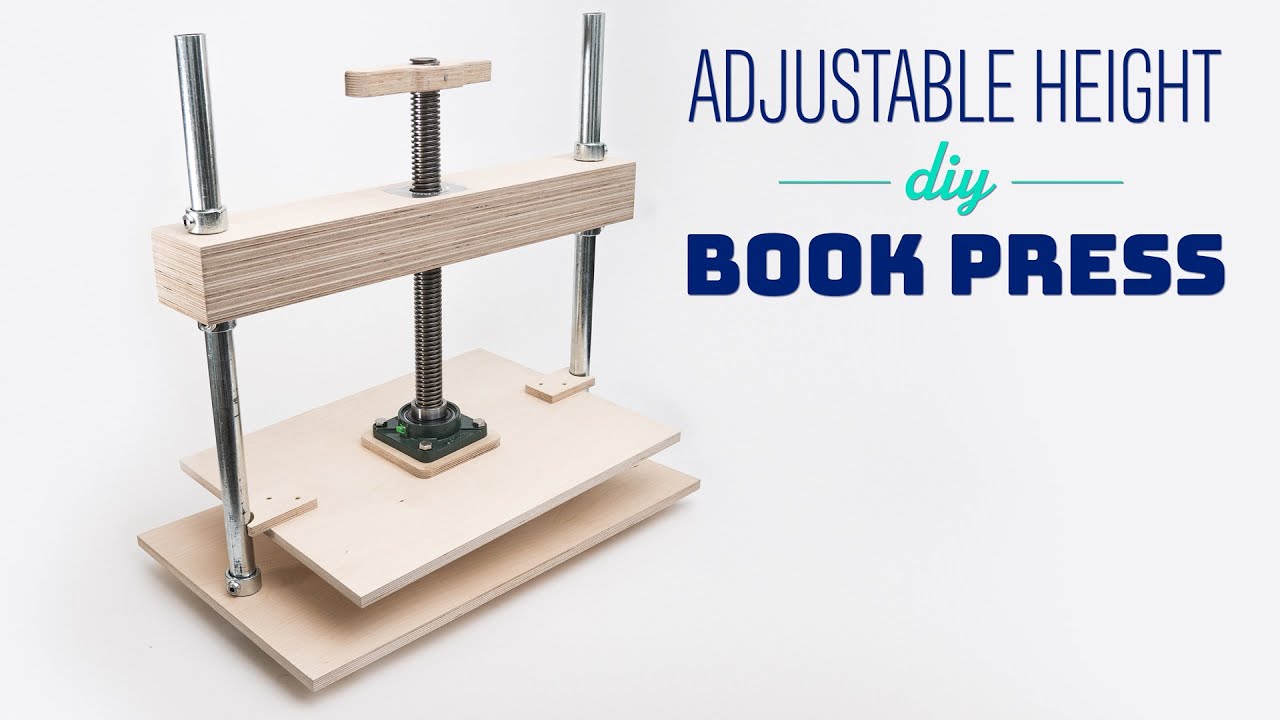

DIY Book Press 1 2 3 A book press is used to evenly flatten handmade books. They can hold pages securely while gluing, and prevent covers from warping while the glue dries. Book presses can sell for hundreds of dollars, but you can make your own basic version at home in 10 minutes, for around $10. Tips: 1 Step 1: Gather the Parts. I had to ask my wife what size books she'd be pressing. She told me that most books are 30cm tall, or less. So I designed for 1 foot of book. If you are going to press bigger books, you might have to alter some of these dimensions. But that's what I built. The fact that my book press cost under $25 to make versus Jim's admittedly much more professional one that costs $60 doesn't displease me.. (assuming you can't want walk a straight line for whatever reason). The DIY solution is humorous, however. I grabbed some clothespins from the laundry room to anchor the bolts in place. Secondarily. When your book block has dried, put a small amount of glue on either end and glue these "end papers" to the block. Smear glue on the inside of your cover and stick the outsides of your end papers to the cover. Close the book and clamp it between boards or put it under something heavy, and leave it to dry overnight.

How to build a DIY book press // LARGE A2 Size! YouTube

Paper Crafts Sharing is caring! Making your own books, notebooks, and binders can be a great hobby. I love to create my own customized binders and journals. However, to do so, I needed a good bookbinding press. Heads up, folks! If this post looks familiar to you, your eyes are not deceiving you. DIY Book Press on the Cheap! Mike Deakin 30.9K subscribers Subscribe Subscribed L i k e Share 47K views 5 years ago Today I'm sharing a book press that I made for only a few pounds using.

Step 3: Corner Drills. Still leaving the 2 bits of wood clamped together, I used a ruler to mark 1cm in from each corner. This is to mark the hole for the bolts. I did this on each corner. I then took it over to the drill press and started by drilling 2mm pilot holes. Book press: if you are only making a book press, skip this step. The watercolor paper and cardboard will be stacked in the press to hold the flowers and absorb any moisture as they are pressed and dried. Depending on the size of your press, you will need to trim the watercolor paper and cardboard to accommodate the bolts.

Finished My Book Press. r/bookbinding

Jul 29, 2013 - Explore Jennifer Phillips's board "HOMEMADE BOOK PRESS", followed by 185 people on Pinterest. See more ideas about book press, homemade books, book binding. If anybody follows my design, I do suggest two improvements: Make the base layer thicker, probably 3 times as thick, so that it doesn't bow under heavy pressure. I would do the same for the top, but maybe only 2 times as thick, since the top bending slightly is not as big of an issue. Secure the posts to the base better.