History:How to Remove Hydraulic Cylinder caps5 techniquesStrong grip on the cylinder is very important.1- wrench for hydraulic capsThis is the wrench desi. Remove the end cap: Once the bolts are loosened, use the hydraulic cylinder end cap removal tool (if available) or a wrench to gently pry the end cap off the cylinder. If the end cap is stuck, tap it lightly with a rubber mallet to loosen it. Inspect the inside of the cylinder: Once the end cap is removed, inspect the inside of the cylinder for.

How to Remove a Hydraulic Cylinder End Cap

In this video I show how I removed the end cap (gland nut) (hydraulic cylinder head) from the tilt cylinder on my bobcat. I ended up using a breaker bar on t. A hydraulic cylinder functions as the primary driver at the heart of many kinds of machinery. Small issues can have larger knock-on effects to the rest of the associated parts as well as potential injuries to those operating it. There is so much of more information in this post Hydraulic Cylinder Issues, Service & Repair - Hydramech. In this video i engineer a way to remove a cross-threaded hydraulic cylinder cap. or "gland" (whatever). The Wrong Way to Remove a Piston Rod and End Cap. Students at a technical college were going to learn how to disassemble a hydraulic cylinder. In this case, the cylinder was a round, welded design with the rod gland retained on the ID of the cylinder tube. Students removed the gland retaining ring, then laid the cylinder on the floor.

How To Remove A Hydraulic Cylinder End Cap

Temperature can be a valuable ally when trying to remove stubborn components. Here's when and how to use it: Using Heat: Applying controlled heat can expand metal, potentially breaking the bond between the end cap and the cylinder. Use a propane torch and move it in a steady motion around the end cap's circumference. Use a socket wrench and socket set to loosen the bolts holding the end cap in place. If the bolts are stuck, use a pipe wrench for extra leverage. Once the bolts are loose, use a hex key to unscrew them completely. Once the bolts are removed, use a screwdriver to pry off the end cap. 2. Remove the external steel wire ring. 3. Remove any dirt that may have accumulated on the cylinder head. 4. Using the mallet and punch, push the head into the cylinder tube until the. is fully exposed. This will also move the internal wire ring into its removal position. 5. 4. Remove the End Cap. Once the hydraulic lines are disconnected, you can then begin to remove the end cap. This is done by unscrewing the cap from the cylinder body. Be sure to use the appropriate tools for this task. 5. Inspect the End Cap. After the end cap is removed, it is important to inspect it for any signs of damage or wear.

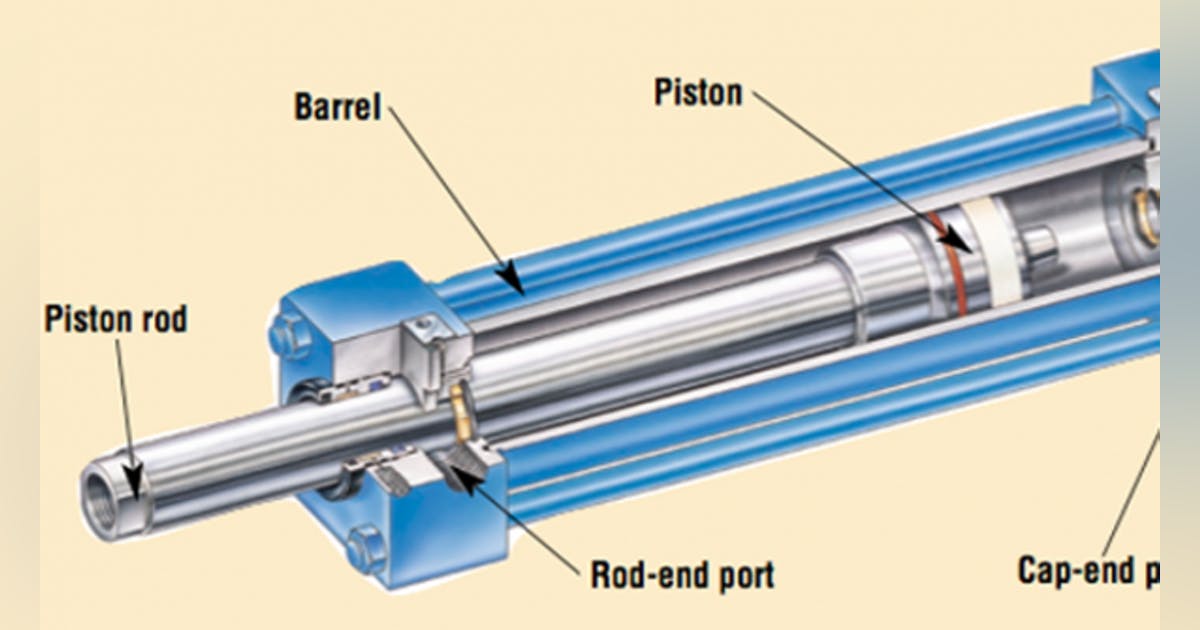

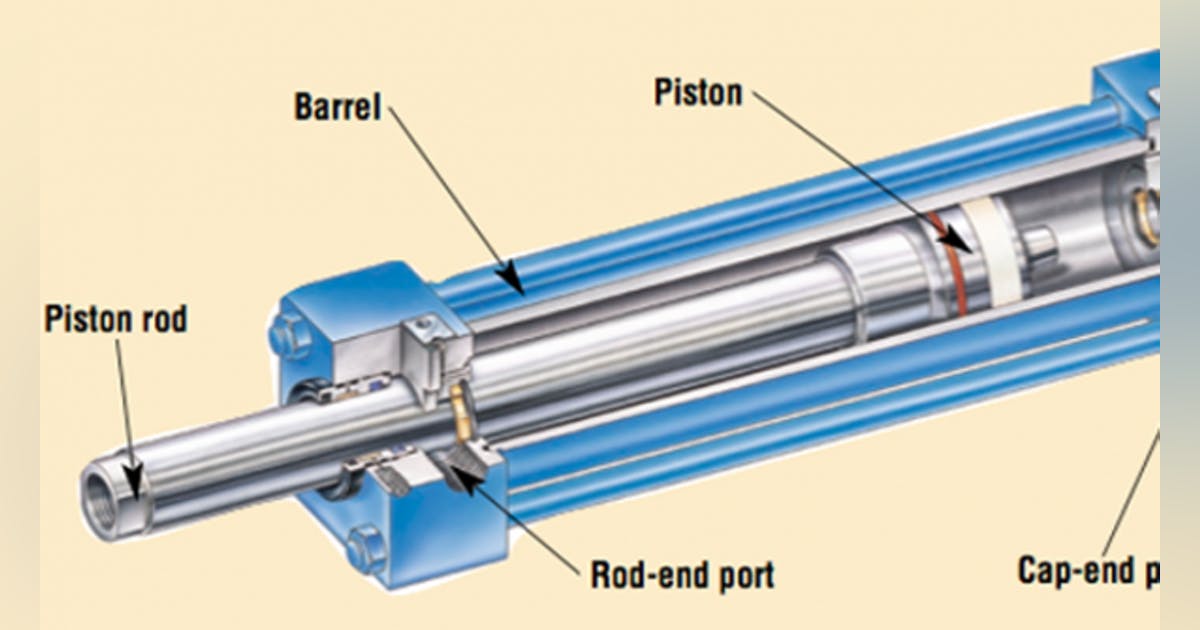

A Pneumatic Cylinder is a device which generates reciprocating linear

How to Remove Hydraulic End Caps Using Our Impact Tool. The Marine Tech trim and tilt impact tool attaches to a standard air hammer (10mm shank) and then hooks into any of the holes on your end cap. It's very easy and quick to use: simply snap it into the air hammer, apply it to the end cap, and let the air hammer do its job. Plug the port in the rod end of the cylinder with a suitable plug that has the proper pressure rating. Tilt the cap-end of the cylinder upwards slightly and place suitable spacer (about 1 in.) under it. Fill the cylinder (through the cap-end port) with hydraulic oil. Connect a 300-psi mechanical hand-pump with pressure gauge to the closed-end port.

The removal of a hydraulic cylinder end cap requires careful execution to ensure a safe and successful disassembly process. By following this step-by-step guide, you can safely remove the hydraulic cylinder end cap for maintenance, repair, or replacement purposes. Remember to exercise caution, use appropriate tools, and inspect the components. Take a tour of our VR factory! Search for:

(1).jpg)

Tie Rod Hydraulic Cylinder Repair & Rebuild Cylinders, Inc.

Step 2: Saw the plywood to the desired size. Be sure to use a circular saw to ensure accurate cuts. Step 3: Fit the end cap onto the tractor hydraulic cylinder and mark where it sits on the cylinder. Use a ruler or a straight edge to make sure that the end cap fits snugly onto the cylinder. Step 4: Drill a 1/4 inch hole into the marked location. Pry the cap off. With the end cap loose, use a pry bar or screwdriver to gently pry the cap off the cylinder body. Be careful not to damage the sealing surfaces or the cylinder body. 5. Check the seal. Once the end cap is removed, check the seal and the cylinder bore for any damage or wear. If everything looks good, you can reassemble the.

(1).jpg)