The Base This is the part of a vise that holds it all together, literally. The base of a vise is the part that is secured to your bench. There are different types of bases, however. Some bases are designed to be clamped into place, while others are bolted down. There are also vacuum and swivel bases available for different purposes. The Jaw Choose from our selection of vise replacement parts, including bench vise jaws, drop-in bench vise jaw liners, and more. In stock and ready to ship.

Top 75 of Parts Of A Bench Vice specialsonlittlestpet94919

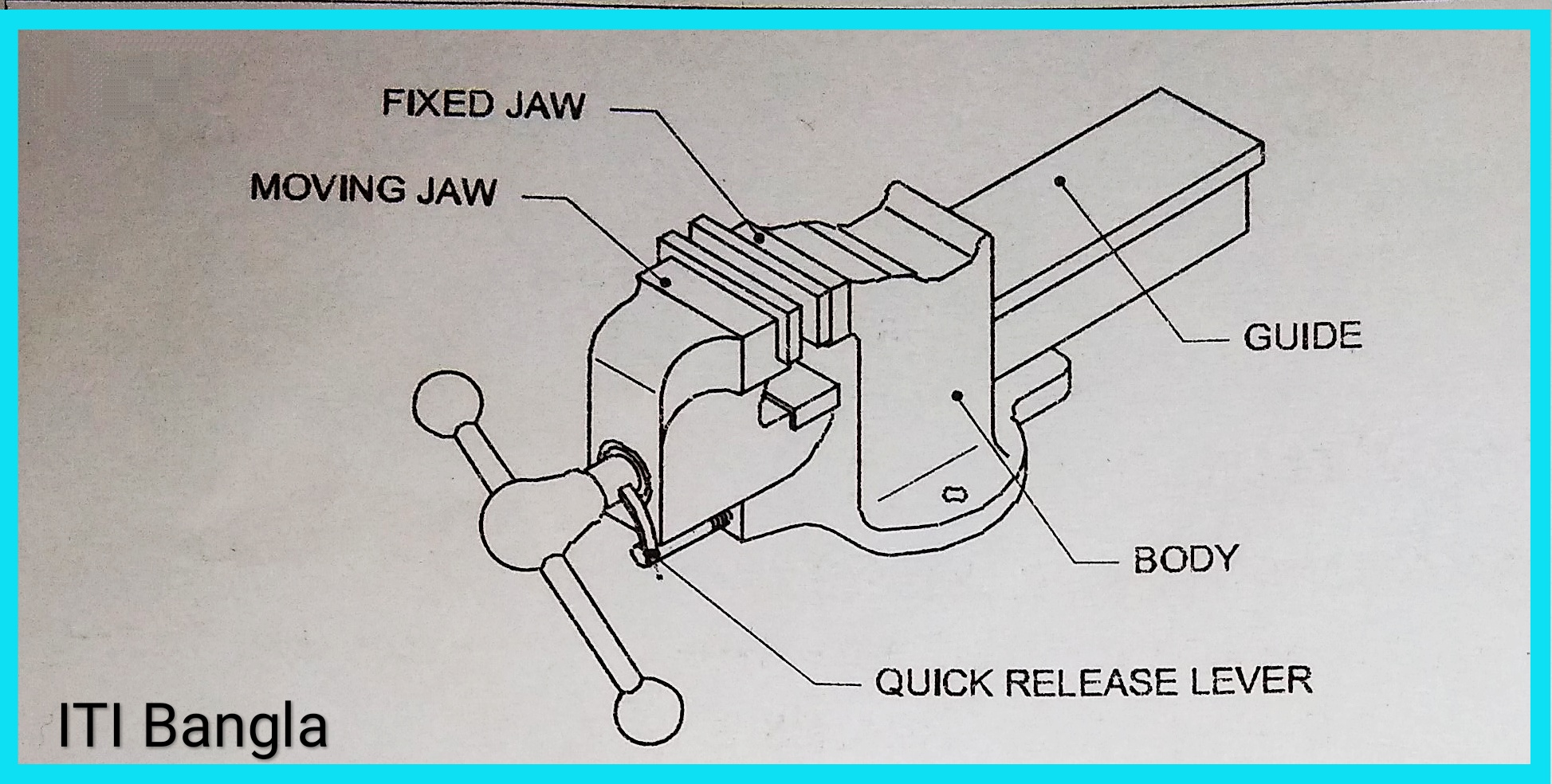

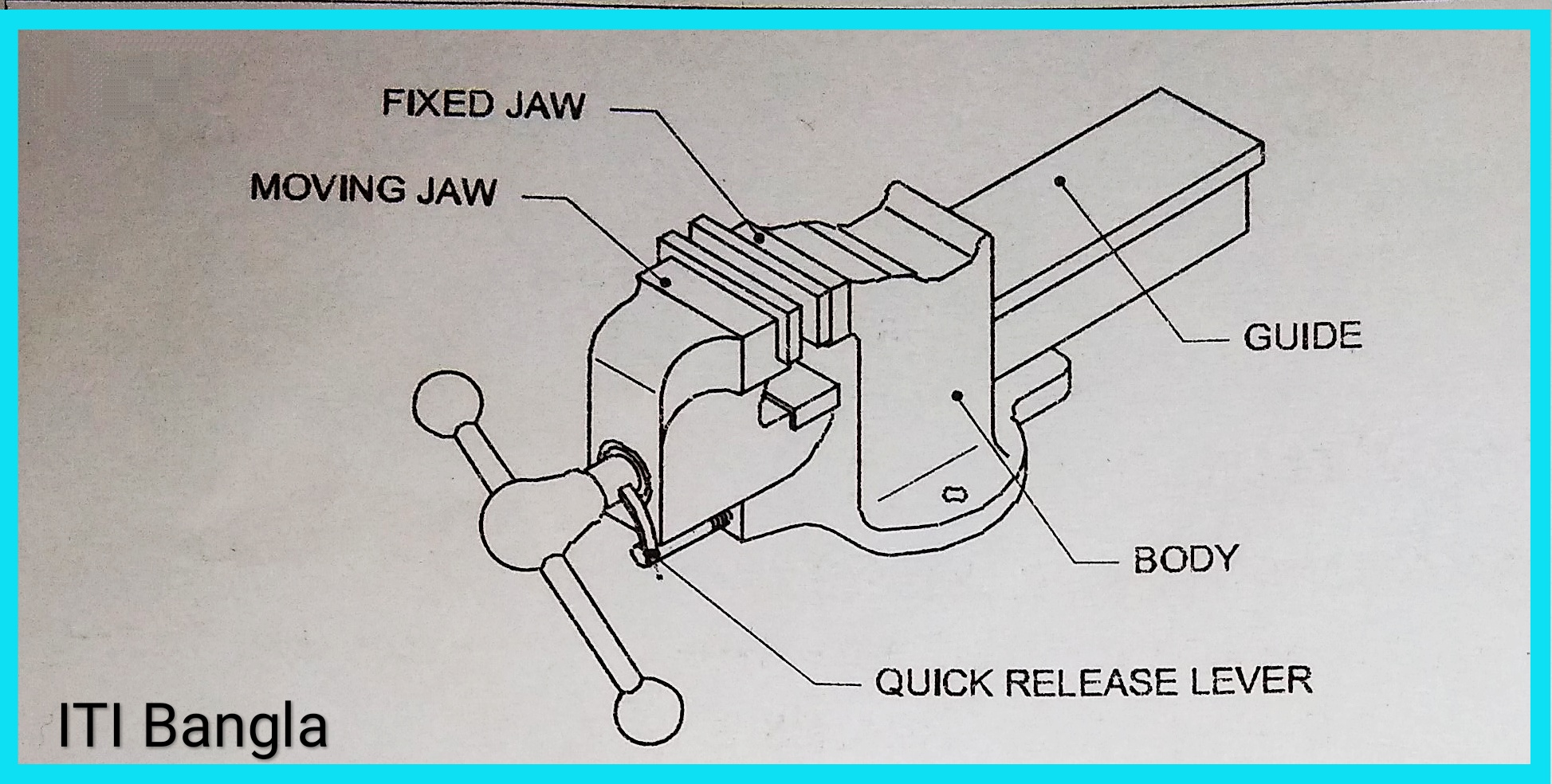

The main parts of a metalworking vice are the base, fixed body, slide, stationary jaw, sliding jaw, screw and handle. Read more about all the different parts and their purpose in our expert guide below. See Latest Prices Jaws A vice has two jaws: a stationary jaw and a sliding jaw. How to Use? Explained with its parts, types, construction, how each type of vice works with diagram. And also you can download the PDF file of this article. What is Vice? Contents show The featured components include serrated steel jaws, precision slide bar, and an ACME-threaded main screw. Fasteners should be purchased, and fasteners for attaching the jaws to the vise will often include an additional set of replacement jaws, to be installed when the first set wears out. Machine vise parts and accessories are components that are used for maintaining or modifying vises. They include jaws and jaw plates for replacing worn parts, fasteners for attaching vise components, kits for repairing vises, and adapters for mounting vises to different types of machines or worktables.

Vise Parts Blacksmith Pics

The main parts of a basic vise vise are the vise base, vise body, lead screw , handle, sliding jaw, and stationary jaw. Swivel vises will have a few more parts which allow it to swivel 360 degrees. These parts include an inner base plate which rest inside an outer base plate which sits under the vise body. Base. Machine vices are often manufactured with a flat bottom base design which fits firmly against the machine's table. This allows the vice to fit on the table in horizontal alignment with the drill bit. The base is also designed with holes through the bottom, in order to allow the drill to pass through during applications. Main Screw, Slide, and Handle. Together these parts of the bench vise make it do its job. When you turn the handle the slide is the part that moves the jaw. The main screw is attached to the handle so the force you apply to the handle rotates the main screw. The main screw in turn uses your force to clamp the jaws of the vise. The Slide. The part moves when you turn the handle of the vice. It applies force to the object. It is connected to the sliding jaw. Handle. One of the most sophisticated parts of the bench vices is its handle. The lever is attached to the handle. When turning the handle, make sure not to overtighten it.

Types of Vices, Bench Vice, Machine Vice, Pipe Vice, Hand Vice, Leg

Mill a Strip of Parts in a Vise. So you want to make a bunch of small parts at once in one setup, and using one vise. Make a strip of parts in a set of big soft jaws: The parts keep a strip underneath. To finish, flip the whole thing, drop it into softjaws of appropriate "negative image" of the parts, and mill of the back. 1. The Base The base of the vise is the part that holds everything together. It is truly the life of the party. The base of the vise is fastened to the bench and it comes in different designs. Some can be clamped in place; the others can be bolted. There are also swivel and vacuum bases available for different purposes. 2. The Jaw

Add to cart. Handle, W/Nut BC410. Fix Number FIX10096842. Manufacturer Part Number 41050. This is a genuine OEM replacement part that has been sourced directly from Rigid. This handle assembly is most commonly used with chain vises. The assembly comes with the handle, the nut, and the friction ring. Clean the Table and Tram the Machinist Vise. Before putting any vise on your machine table, be sure to clean the table of chips. You don't want to trap a chip between the vise or table. If you have a T-Slot table you're mounting the vise to, you'll probably want to tram the vise as well. Tramming a vise is the procedure of using an.

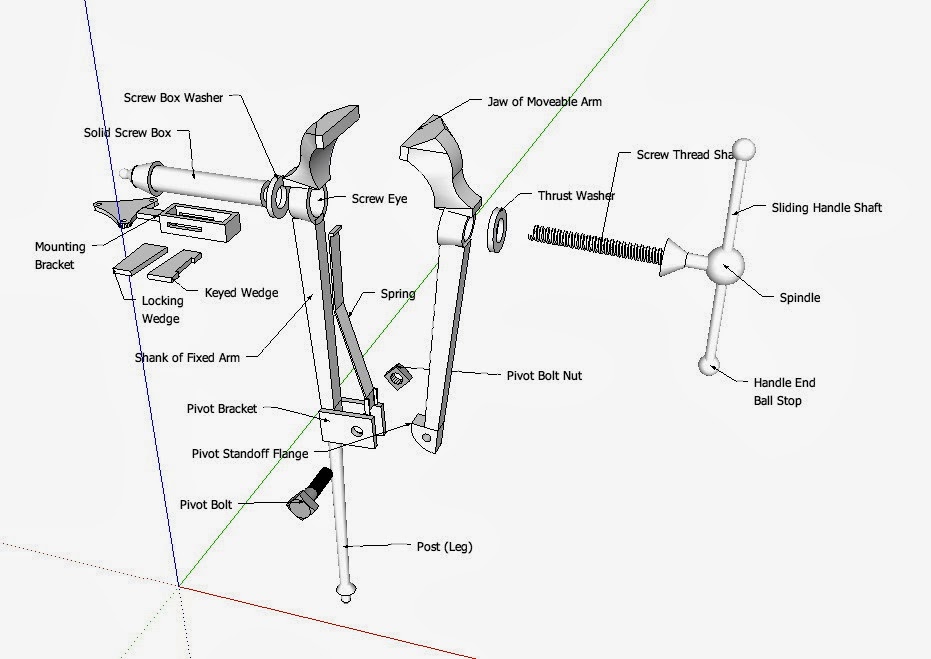

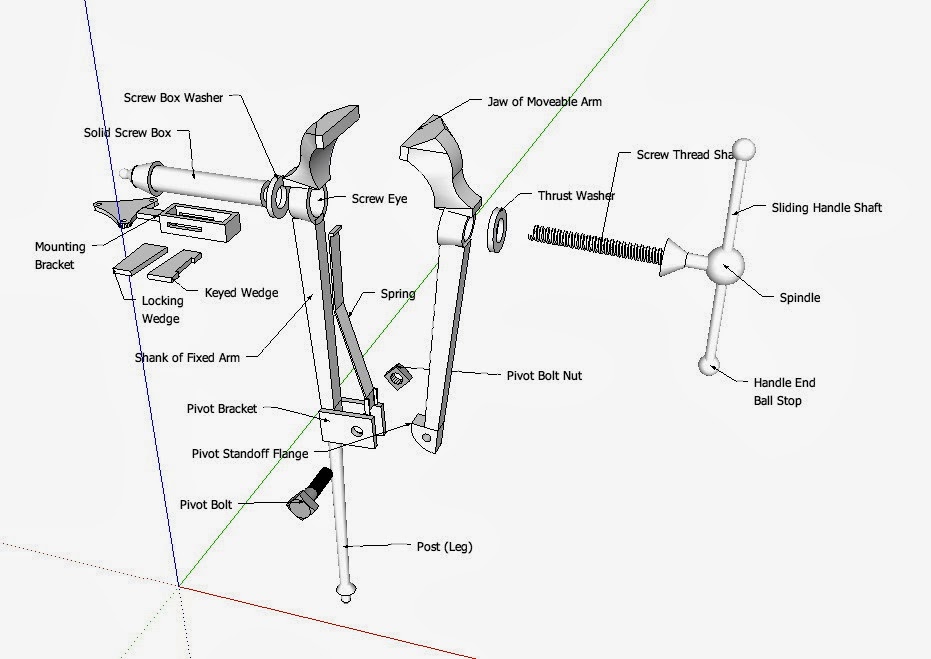

Persimmon Professional Blacksmithing Post Vise Diagram

Usage. Bench Vice. - Stationary, attached to a workbench or table. - Usually made of cast iron or steel Engineer's Vice. - Heavy-duty, steel jaws. - Often equipped with an anvil on the back. - Clamping woodworking or metalworking items. - Holding material steady during drilling, cutting, etc. - Holding metal parts for machining. This makes replacement parts such as screws boxes (nuts) and springs very specific to a given vise. Multiply these differences by dozens of manufacturers and there could be thousands of variations. Screws for these vises range from about 1" to 1-1/2" diameter in 1/16" increments or a dozen sizes.