Do this by using a taut string line or a long, straight board. Remember to raise the tie-in framing on the existing house roof ¾ in. above the porch framing to compensate for the difference in thickness of the 3/4-in. plywood and 1-1/2-in. roof boards, so use 3/4-in.-thick spacer blocks to raise the line to the correct tie-in framing height. Hold a screen panel against the ceiling and floor cleats. On the six-foot step ladder, drill two holes at top, through both the screen frame and the ceiling cleat. Insert two 3 1/2-inch bolts through the holes and add washers and wing nuts to the back. Repeat at the floor cleat.

Wood Porch Framing Details Porch wood, Porch beams, Deck footings

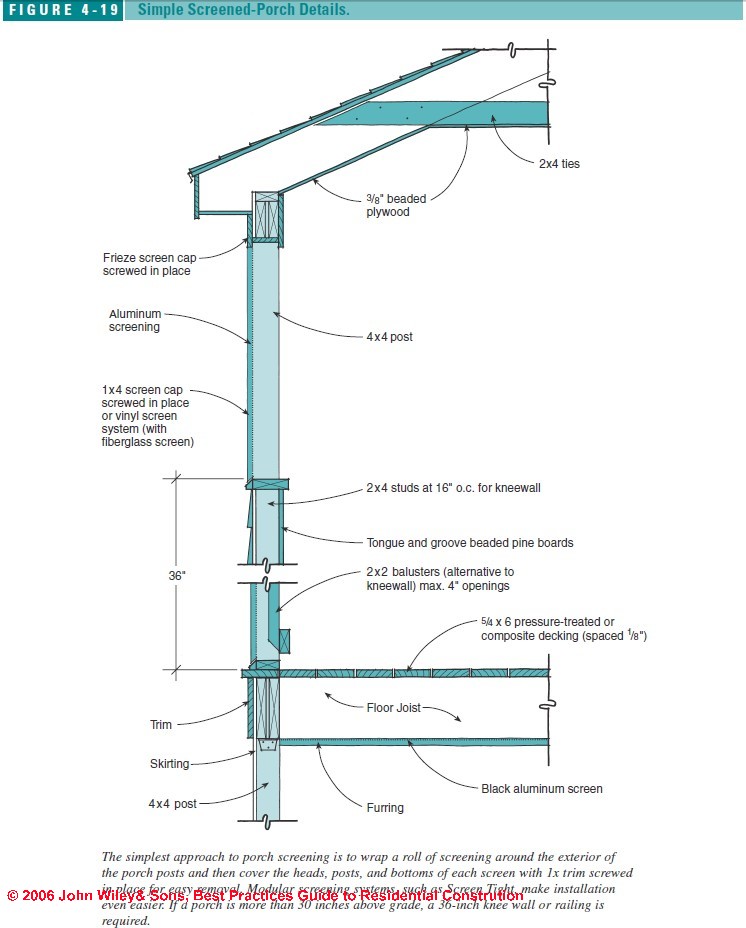

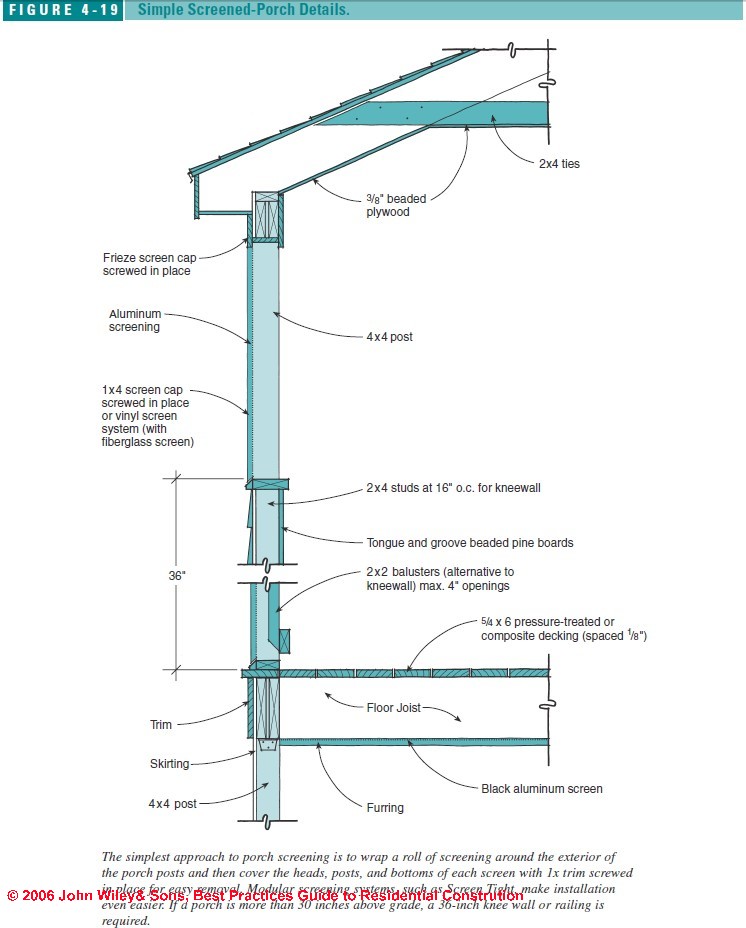

Affix the ledger board, which runs the width of the porch and attaches the porch to the house. Remove siding, if necessary, in this section using a utility knife to help. Strike a level line with the laser level. Attach the ledger board at the desired height with the 1/2-inch lag screws, using the ratchet wrench. Use a manufactured screening system such as Screen Tight™ (One Better Way), a vinyl snap-in-place system for fiberglass screening that screws onto the exterior face of the porch framing. Staple aluminum screening to the exterior of the 4x4 posts and trim with 1x wood trim pieces screwed in place. 2. Sketch in the porch's major areas. Draw in any supports, columns, fences, steps, or other characteristics of your porch. Include defining traits for your porch's style that you wish to include. If you're designing a Queen Anne front porch, for example, you might sketch ornate railing and woodwork. [9] 3. How to build a front porch. Building the posts. The first step of the project is to set the posts into place. Therefore, use 6×6 lumber to build the posts in the manner described in the diagram. Make several cuts inside the marked area and clean the 3″ deep recess with a chisel. Smart Tip: Smooth the surface with a sanding block.

Porch Construction & Porch Screening Installation Details

Step 10: Add the Porch Floor or Decking. Attach the decking allowing for a small space in between each board. The decking will have a slight overhang from the edge. Later, you may want to sand your new front porch and clean up any stray pieces in preparation to paint or stain it, if that is part of your plans. How to build a covered front porch in 5 easy steps is what this video is about. I show you how to frame a covered front porch for composite trex decking or f. For comfortable seating, a porch needs to be at least 6 feet deep. If you'd like a table for outside dining, you need at least 10 feet of depth. Width depends on the house. A porch can partially cover the front of the house, mainly offering shelter to the front door. It also can run the width of the house or wrap around it. Use washers, and countersink the washers and the lag bolt heads. Tack sill seal—1/2-in. thick foam strips to block bugs and water drips—to the back of the posts and beam. Then raise the assembly in place, dropping the posts onto the drift pins. Hold the posts in place with temporary 2×4 diagonal braces.

Porch Framing Details Decks Porches JHMRad 154821

Porches can be prime architectural features, especially on houses built from the mid-1800s to the early 1900s. Porches from this Golden Age are not only major expressions of a building's style, but since the vast majority were constructed of wood they are equally important examples of historic millwork. When I began making millwork for my own. Follow the complete deck ledger installation process from prep to fastening to flashing. 2. Attach a Deck to Any Wall. Builder Mike Guertin outlines code-compliant ledger and lateral-tie details for all types of deck builds. How-To 3. A Solid Deck Begins with Concrete Piers.

Details are shown in this 2015 IRC illustration. CLICK TO ENLARGE. Each connector screws or nails into the bottom of a deck joist and is fastened to the house framing with a single 3/8″ lag screw. The lag screws must penetrate 3 inches (all threaded) into the house framing — into a top plate, stud, header, or sill plate. Details How to. Screen Wall. Modular screen porch framing system made of rigid PVC vinyl and composite fiber additives to withstand extreme wind and weather. Details How to. FASTtrack. A versatile aluminum framing system for unlimited screen porch configurations, complex screening and expansive openings.

How To Get The Best Porch Roof Framing Design — Randolph Indoor and

Sandwich a piece of 1/2 inch plywood in between the boards and nail together. When building a porch roof, the header carries most of the weight of the roof. Ensure that it is substantial. Place the header on top of the columns and secure by toe nailing. Continue this process the length of the porch. Expert advice and attention to detail ensure a successful project. From constructing a sturdy frame to adding the finishing touches, building a covered porch requires patience, precision, and creativity.. Building the porch frame is a critical step that forms the basis for the rest of the construction process. Take your time to ensure that.