12. @ O @ O @ O @ O @ SPIRAL NOTES : TURNS AT 'F' SPACING. K = EXTRA TURNS (HALF T. 4B.) XM PLAIN SPIRAL WITH SPACERS LOOSE. PLAIN SPIRAL WITH SPACERS MOUNTED. (D Unless otherwise noted, DIAMETER "D" is the same for all bends and hooks on a bar. Where slope differs from 450 dimensions, "H" and "K" must be shown. Rebar Angled Bend with Center Line Length Equation and Calculator, L = A + C (in, mm) Re-Bar Channel 90° Degree Bend Unequal Length Legs with Center Line Length Equation and Calculator Rebar Ninety (90°) Degree and 180° Bend with Center Line Length Equation and Calculator

Rebar Bending Radius Chart Home Interior Design

1. asa Standard Bar Bends include only Types 1-32. Tl.T16, and Sl.S15. 2. All dimensions are Out-to-out of bar except "A" and "G" on standard and 1350 hooks. 3. "J" dimension on 1800 hooks to be shown only where necessary to restrict hook size, otherwise standard hooks are to be used. 4. 7.4.3 Special Bend Diameter Requirements for 7-16 Galvanized Reinforcing Bars 7.4.4 Sizing of Bending Pins 7-16 7.4.5 Inspection of Finished Bent Bars 7-16 7.5 Typical Measuring Points 7-17 7.6 Standard Fabricating Tolerances 7-20 7.7 Bend Curvature 7-22 7.8 Special Bend Shapes 7-23 2.2.1 Bending and bending stresses in reinforced concrete members—Many structural members are required to carry loads that cause bending stresses. An example is a simply-supported beam, in which the top of the member is subjected to compression lengthwise while the bottom is subjected to tension lengthwise (Fig. 2.2.1(a)). This is referred to. and other Bending (Radius Bending being defined as all bends Bent with >1 Radius in any one bar, or a combination of Radius Thru #18 Bars that are bent >6 Points; Bent >1 Plane; Radius B LIGHT BENDING - All #3 and all Stirrups, Column Ties and #4 K D J H C (TYP) DIA concrete. 5. "H" dimension stirrups to be shown where necessary to fit within.

Rebar Bending Radius Chart Best Picture Of Chart

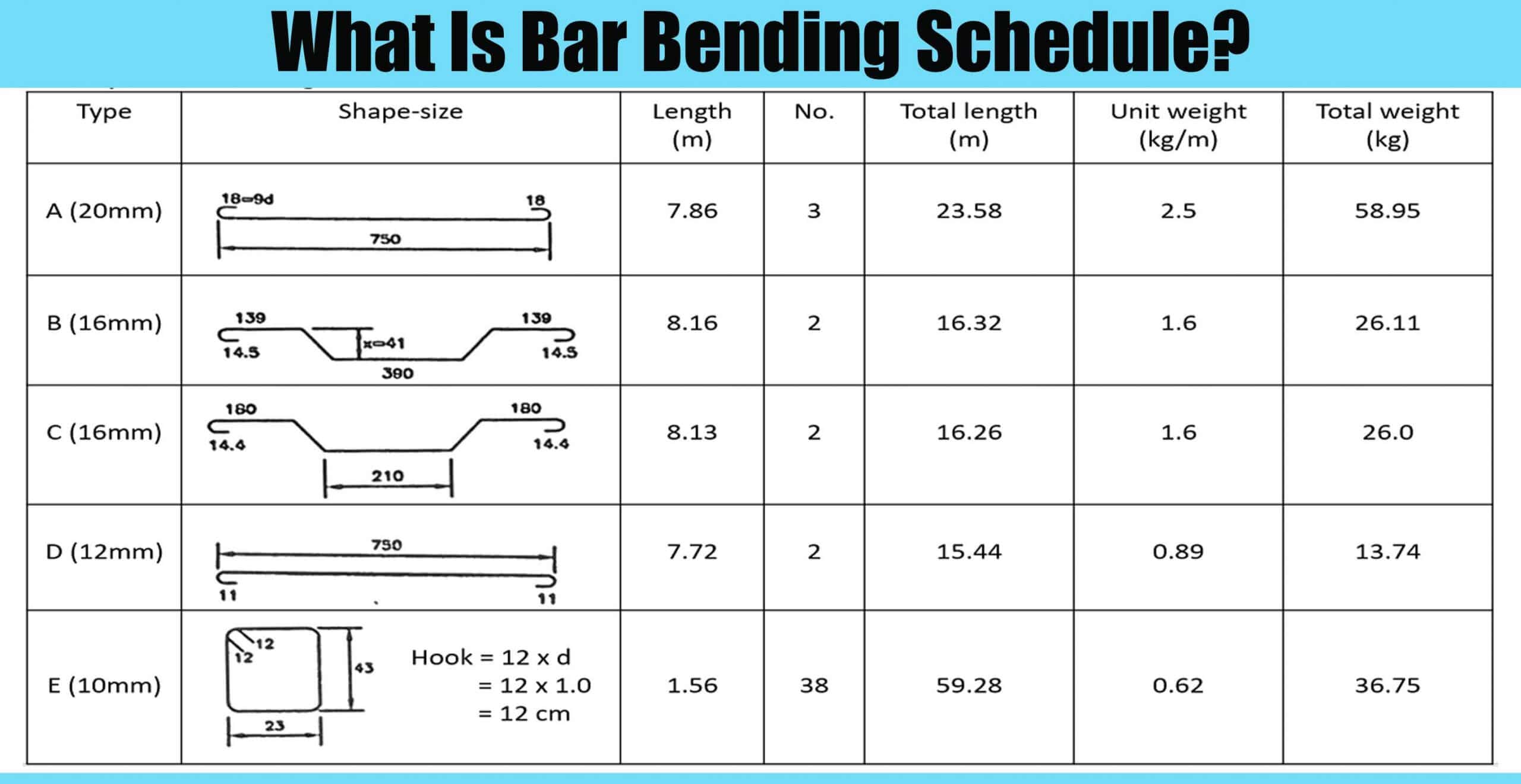

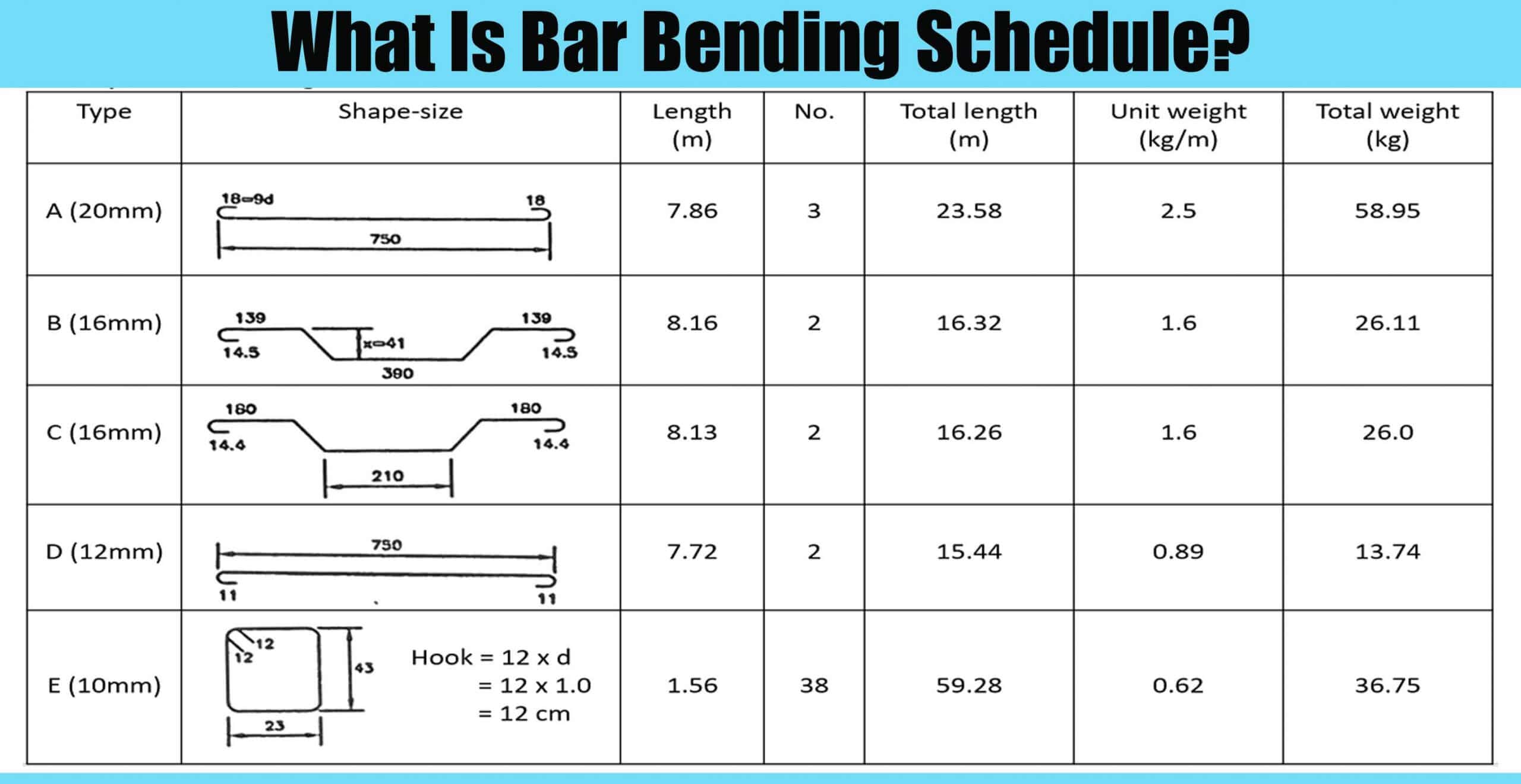

1 Understand the structural issues possible with manually-bent rebar and know how to avoid them. When you bend metal, you naturally weaken it. When done correctly, however, you can minimize damage and still get the shape you need to complete the project. Keep the following in mind as you work: A bar bending schedule is a document showing the list of structural members, bar mark, type of reinforcement, size of rebar, number of rebars for each member, cutting length, total length, shape, and location/spacing/position of all reinforcements in the working drawing. Fill out online for free. without registration or credit card. The Standard Rebar Bend Dimensions Chart is used as a reference guide to determine the appropriate dimensions for bending reinforcing bars (rebar) in construction projects. It helps construction workers accurately bend the rebar to ensure proper reinforcement of concrete structures. Prepare a table or spreadsheet (bar bending schedule format) listing the rebar size, shape, and total length for each element. Review the schedule with the structural engineer or project manager to ensure that it is complete and accurate. Provide a copy of the schedule to the rebar fabricator and the construction crew.

Everything about Bar Bending Schedule BBS Terms & Rules CivilDigital

#1. The Rebar Size and Diameter Depending on the country, there are different rebar metric sizes. Below is the ASTM rebar sizes standard in the US, where the steel rebar sizes start from #3 to #18. Here is the basic information about the first five sizes of rebar. #3 Rebar must be heated prior to straightening and re‐bending • Bar sizes #6 through #11 must be heated prior to straightening and/or bending BMA Engineering, Inc. - 5000 17 Field Bending of Reinforcing Steel BMA Engineering, Inc. - 5000 18 Field Bending of Reinforcing Steel BMA Engineering, Inc. - 5000 19

The standard length of reinforcement bar - 12 metre or 40 feet. Weight of bar (Kg) per metre formula - D2/162. Extension Length Formulas. Footing lap length formula - 40d. Column Lap length formula - 50d. Development length for dowel bars - 16d. Hook Length - 9d. Concrete Cover. Footing - 75 mm. Rebar / Fabricated Shapes. Pilot Steel specializes in the manufacturing of custom bent reinforcing bars. Over the course of selling rebar for 25 years, we realize that it is a major inconvenience for our customers to cut and bend straight bars themselves. In order to satisfy our customers special project needs, we utilize state of the art rebar.

Bar Bending Schedule Spreadsheet to IS 2502

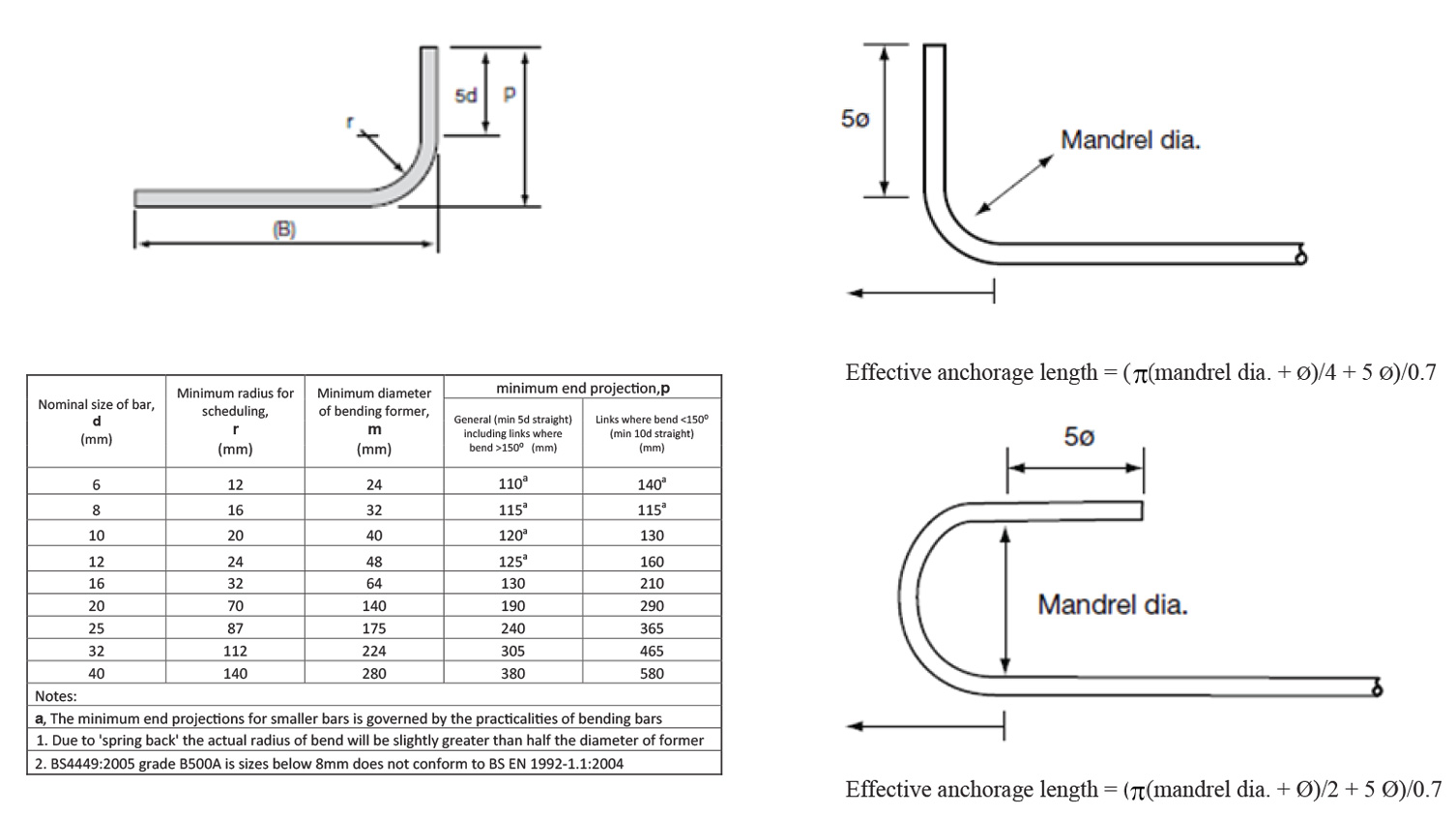

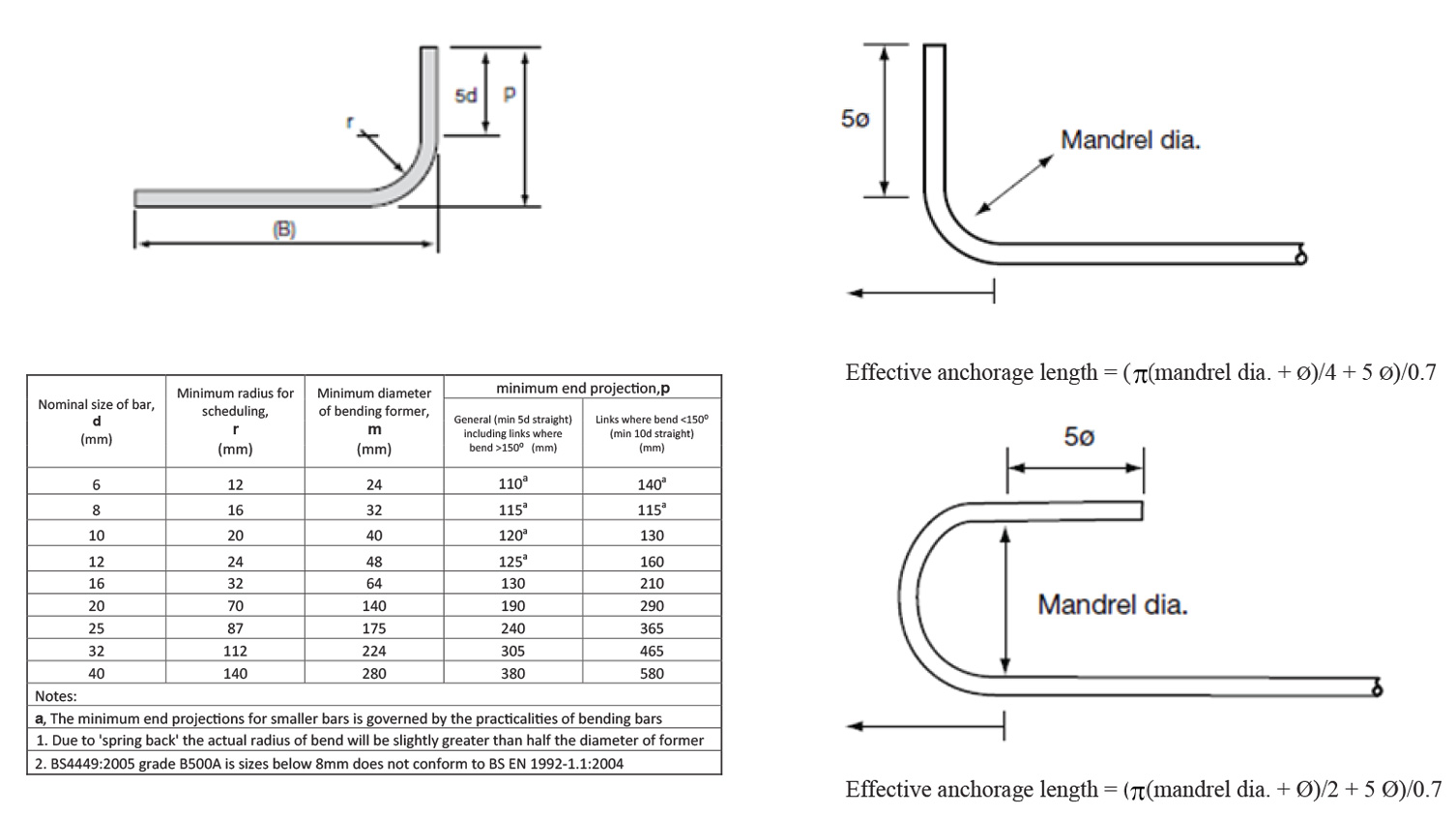

1 2 / 3 0 / 2 0 1 1 8:1 9:0 2 A M R E V I S I O N C:\ d \ p r o j e c t s \ s t a n d a r d s \ s t r u c t u r e s \ c u r r e n t \ r e a d y 4 r e l e a s e \ 2 0. BS8666 is the British Standard rebar shape code list required to be adhered to when using steel to reinforce concrete in construction in the United Kingdom and Northern Ireland. The latest update, BS8666:2020 (from BS8666:2005) updates the standard more closely inline with BS EN 1992-1-1 Eurocode 2 (which you can download for free here ).