Latest Cutting-Edge Technology. Quality Concrete Floor Polishing Services. Contact Us. We Offer a Full Range of Terrazzo Floor and Stair Polishing Services. Contact Us Today! Only today, enjoy all categories up to 90% off your purchase. Hurry & shop mow. Don't swipe away. Massive discounts on our products here - up to 90% off!

the desert edge While You're Out Concrete patio, Backyard landscaping, Concrete

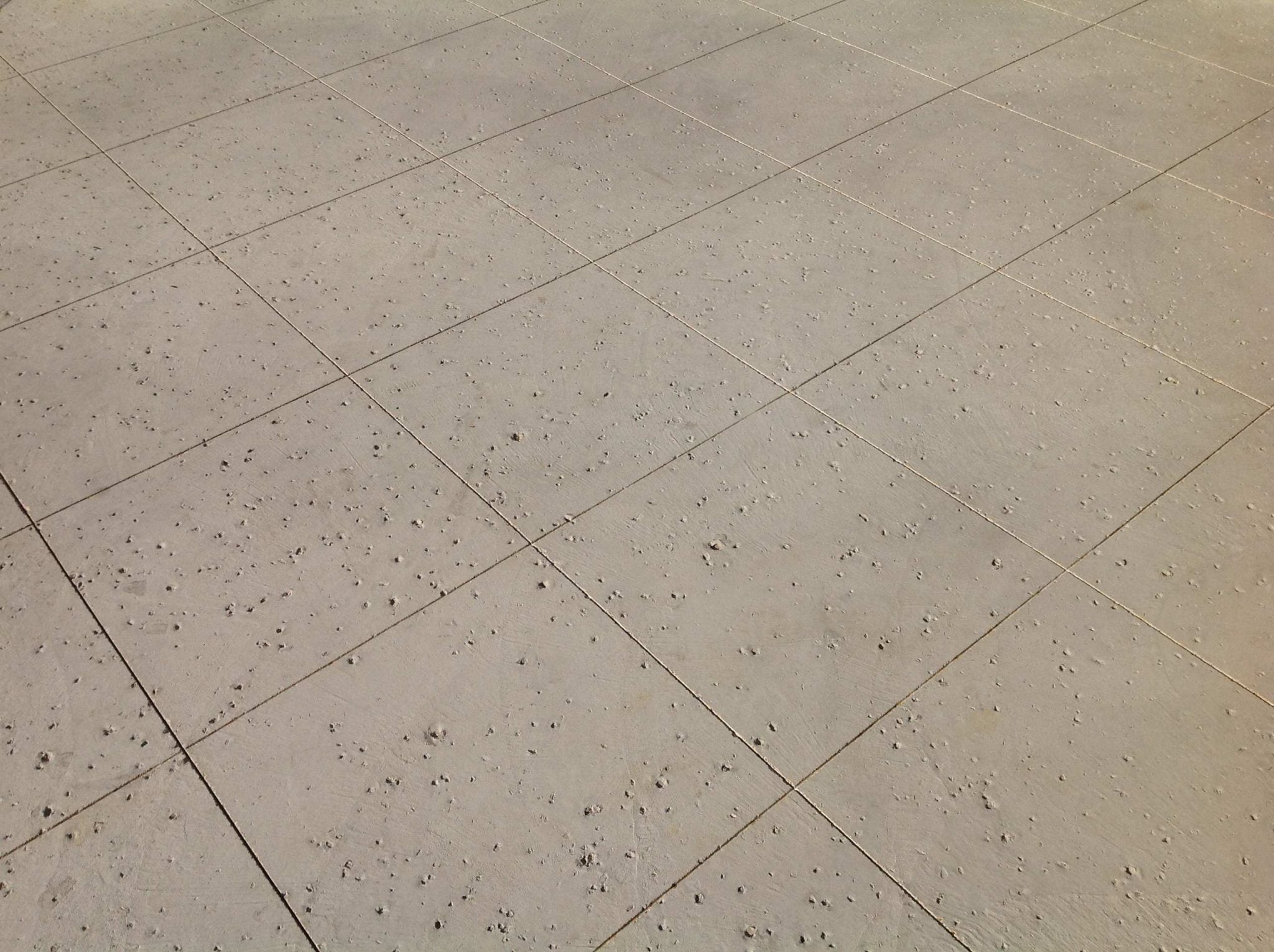

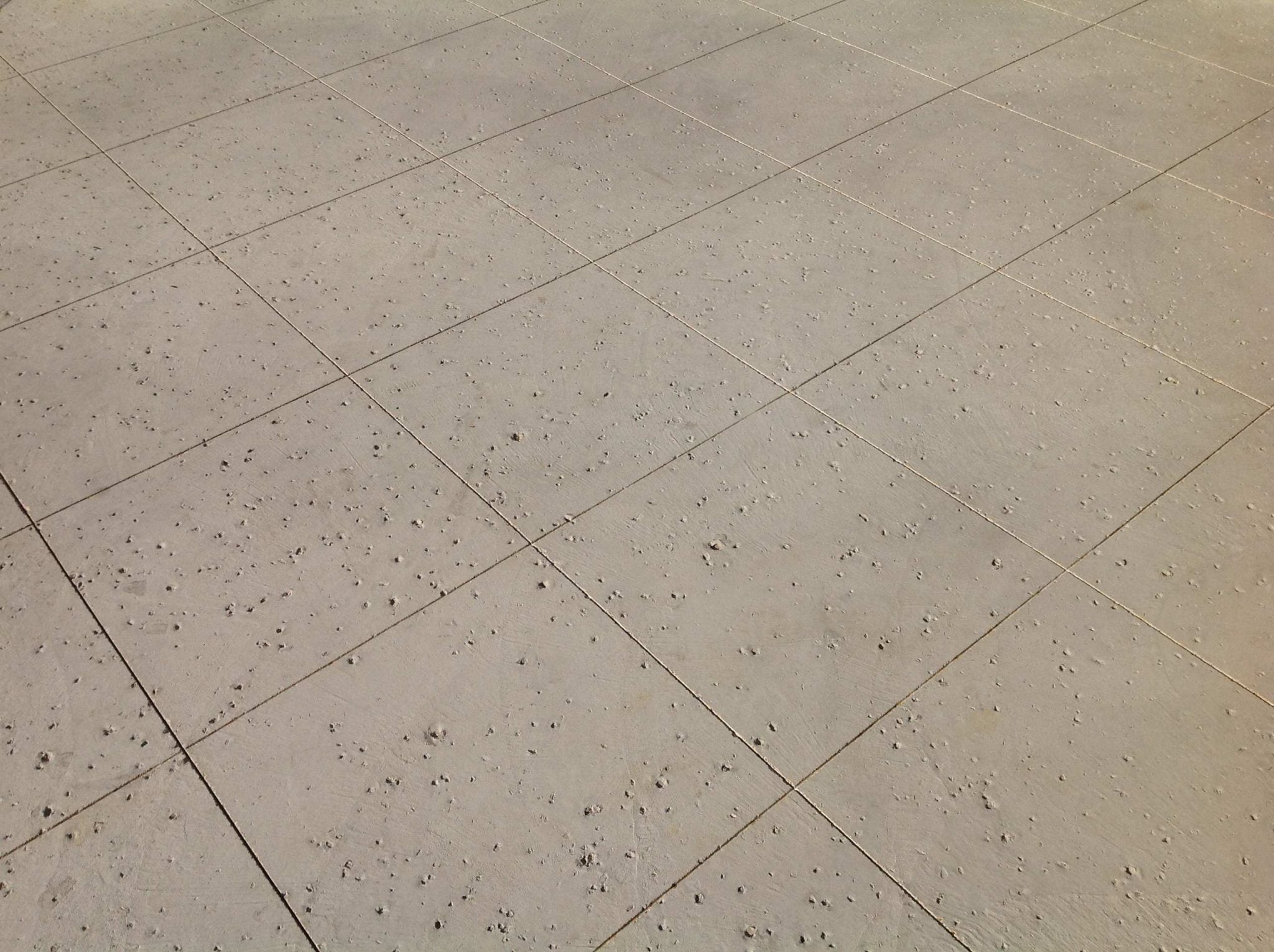

A rock salt concrete finish is an easy and affordable way to add subtle texture and skid resistance to plain or colored concrete. Salt is broadcast and pressed into the surface of wet concrete, once it sets, the salt is washed away, revealing a pattern of shallow indentations. As one of the older, more conventional decorative concrete finishes, salt finish concrete has become the most popular in unfreezing / thaw regions around the country. For a little additional cost, you can add texture to just about any hardscape. With the popularity of decorative concrete along with the wide range of decorative finishes available today, the salt finish is not used much currently. Salt finish is hands down a great and cost-friendly way to dress up what would normally be a regular or average concrete flatwork. As the name suggests, the material consists of salt in its application. It can be achieved by pressing rock salt, preferably that of course texture, onto the surface of freshly laid concrete and then waiting for. Scatter the rock salt onto the concrete surface, taking care to get even distribution. Use more salt for a highly pitted surface. Typical application rates range from 3 to 12 pounds per 100 square feet. Press the salt into the concrete using a trowel or roller. The salt crystals should have half their diameter remaining above the surface.

Rock Salt Texture Stamped Concrete Bud's Concrete, Inc.

Here are the steps involved in achieving a rock salt finish on concrete: Prepare the Surface: Ensure that the concrete surface is clean, dry, and free of any debris or contaminants. Apply the Salt: Spread rock salt evenly over the surface at a rate of about 3-5 pounds per square foot. Trowel the Surface: Use a float or trowel to press the salt. In this video we take you from start to finish how to give your concrete the rock salt finish! We hope you enjoy the video and dont forget to like, comment a. Rock Salt Concrete Finish Problems. Rock Salt Finish Concrete. During low temperatures, there may be chances of water and moisture getting trapped on the surfaces. These moisture and water that trapped in the surfaces will increase the pressure which, eventually will cause cracks in concrete. Salt Finish Concrete Pros and Cons. Pros of Salt. In this video we show you how to pour a concrete patio with a salt rock finish and decorative borders. From demolition, to setup, to the actual pour, we go t.

Rock Salt Finish Concrete Properties, Uses, Advantages & Disadvantages

The crystals of salt are spread evenly over the surface of the concrete for a good quality finish. Rock salt crystals of size 1/8 to 3/8 of an inch are used for salt finish concrete to get desired results. Do not use salt crystals larger than 3/8 of an inch in salt finish concrete. Because large indents motivate risks. The Rock Salt finish concrete is an efficient, easy, and low-cost way to decorate the concrete surface which gives an aesthetic look to the concrete surface. The process includes adding extra rock salt into the fresh concrete surface and letting it get set, Then washing with away with a stream of water.

This is a quick tutorial on how to apply a rock-salt finish to a new cement project. Applying rock salt is a quick and easy way to get a nice finish on your. The Rock Salt finish concrete is an easy and cheap way to decorate concrete surface which provides a mind-blowing aesthetic beauty to the concrete surface. It's done by pushing coarse or extra rock salt into the surface of fresh concrete, permitting the concrete to set, and then washing the salt away with a stream of water.

Rock Salt Finish Rock salt, Concrete pavers, Concrete finish

Specification for rock salt finish concrete. Rock salt crystals of size ranging from 1/8 to 3/8 of an inch can be used for obtaining the desired results. Salt crystals larger than 3/8 of an inch should be avoided to prevent hazards resulting from larger indents. Salt crystals should be pressed and lodged into the concrete surface up to a depth. The first step in manufacturing rock salt finish concrete is the selection of materials. This includes the use of high-quality cement, aggregates, admixtures, and water. The type of coarse aggregate used for this type of concrete is crushed rock salt, which gives the final product its distinctive texture. 2. Mixing.