To rebuild or replace? Moss Motors' Tech specialists show you how to check your wheel cylinders for leaks. In addition they quickly run you through the rebui. A wheel cylinder is a component of a hydraulic drum brake system. [1] It is located in each wheel and is usually positioned at the top of the wheel, above the shoes. Its function is to exert force onto the shoes so as to bring them into contact with the drum and stop the vehicle with friction. [2] The wheel cylinders are usually connected to.

Repair Guides

Use the wheel cylinder to pull the brake pipe through the backplate. Hold the union nut steady with a spanner, and twist the cylinder to free the union completely. When removing the brake pipe, loosen the union nut before taking off the wheel cylinder. When the cylinder is free, use it to pull an inch or two of brake pipe through the backplate. A socket and ratchet should be used to remove the wheel cylinder bolts. These parts are really grimy. Once the cylinder is out, blast the backing plate and brakes with brake cleaner. The new wheel cylinder will reuse the plungers, pop them into the rubber boots on each end. If your hardline survived, you can reuse it. Fixing Leaking Brake Wheel Cylinders. The wheel brake cylinder is vital to your drums braking capability. In this video I show you the process of replacing t. In this video we will learn about how the master cylinder and wheel cylinder works in Hydraulic Braking SystemTimecodes0:00 - Introduction0:06 - Purpose of M.

:max_bytes(150000):strip_icc()/1280px-Master_cylinder_diagram.svg-5a172d594e46ba001a8294ac.png)

Symptoms of Master Cylinder Failure

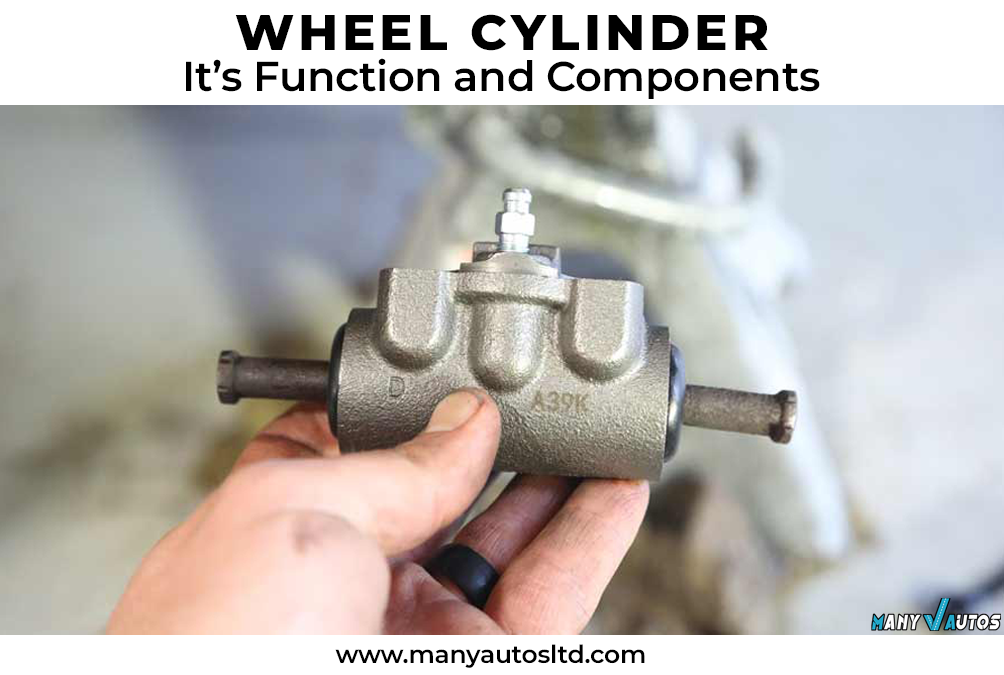

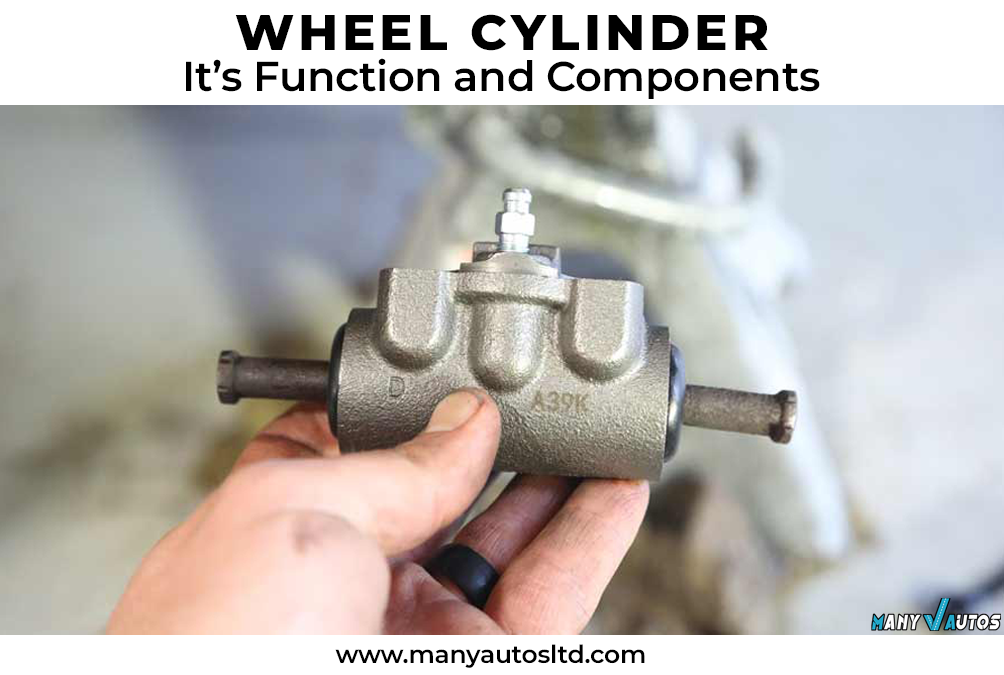

The Anatomy of a Drum Brake Wheel Cylinder. The wheel cylinder structure is relatively simple. Its main body is a cylinder with a bore, typically made of cast iron or aluminium. The iron or aluminium protects it from corrosion and rust. A new wheel cylinder bore is fitted with these: A piston on each end that connects to a brake shoe via a shaft. This manual tool is for making 37-degree flares. This hydraulic tool makes forming perfect 45-degree double flares quick and easy—it's available from Classic Tube. Here is a perfectly formed 45. Photo: Jefferson Bryant. Wheel cylinders themselves are very simple objects. They are typically cast-iron blocks with a large center bore, two steel pistons, two rubber sealing cups, a spring, and two rubber end caps. There are two additional holes drilled into the body, one for the bleeder screw and the other for the fluid line. The wheel cylinder supplies the muscle for a drum brake. Most wheel cylinders are relatively simple: a pair of horizontally opposed pistons mounted inside a cast iron or aluminum housing. A brake line or hose from the master cylinder routes hydraulic pressure to the wheel cylinder, which pushes the pistons out. This forces the brake

Finding and Fixing Problems with Master Cylinders and Brake Boosters

Drum Brake Assembly: Includes shoes, wheel cylinder and drum. Braking System Basics. Disc and drum brakes are based on a hydraulic pressure system. Braking starts with a mechanical force — your foot pressing the brake pedal. The end result is that your vehicle safely stops. Below is a quick explanation of the five points of the system. Typical wheel cylinder seals only seal when there is pressure behind them. Rapid release of the brake pedal creates a vacuum in the system, which causes the seals to relax and air is ingested into.

The system pressure is still 100 psi however now the pistons at the wheels are increased to 3 square inches. Because the pressure in the system is 100 psi and the wheel cylinders (or calipers. A wheel cylinder is a component of a hydraulic drum brake. The wheel cylinder must force apart the brake shoes and press them against the brake drum. This generates friction and the wheel is decelerated. This happens every time the driver presses on the brake pedal. Pressing on the brake pedal generates a hydraulic pressure in the master brake.

What is Wheel Cylinder, It’s Function and Components? Car Services in

We have a complete wheel cylinder diagram to accommodate all your needss. Quote Now. We are an ISO 9001 certified company and our hallmark for success is backed by strictly monitored quality control system. MZW is a well-established manufacturer of a premium wheel cylinder. In recent years, MZW has expanded its customer base and included award. Its diagram, parts,. There are two main types of wheel cylinders: stepped wheel cylinders and single-piston wheel cylinders. #4 Brake Fluid Reservoir. The brake fluid reservoir stores and protects the vehicle's brake fluid so the braking system can function correctly. The storage is usually small and is connected directly to the master.

:max_bytes(150000):strip_icc()/1280px-Master_cylinder_diagram.svg-5a172d594e46ba001a8294ac.png)