Table of Contents What is a Screw Pump? Screw Pump Construction Screw Pump Working Principle Types of Screw Pumps 1) Single Screw Pump 2) Two Screw Pumps 3) Three Screw Pump 4) Four Screw Pump 5) Five Screw Pump Components of Screw Pump Advantages and Disadvantages of Screw Pumps Advantages of Screw Pump Disadvantages of Screw Pump Design Three principal forms exist; In its simplest form (the Archimedes' screw pump or 'water screw' ), a single screw rotates in a cylindrical cavity, thereby gravitationally trapping some material on top of a section of the screw as if it was a scoop, and progressively moving the material along the screw's axle until it is discharged at the top.

Screw Pump Working Animation YouTube

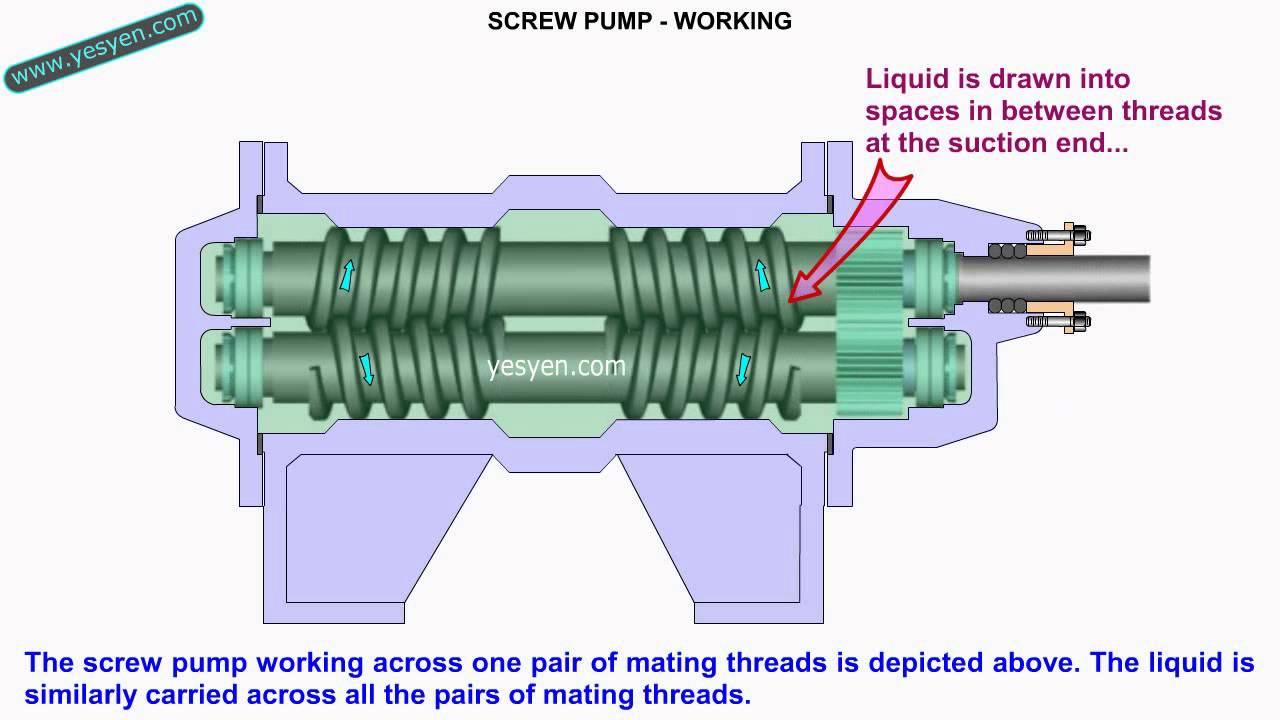

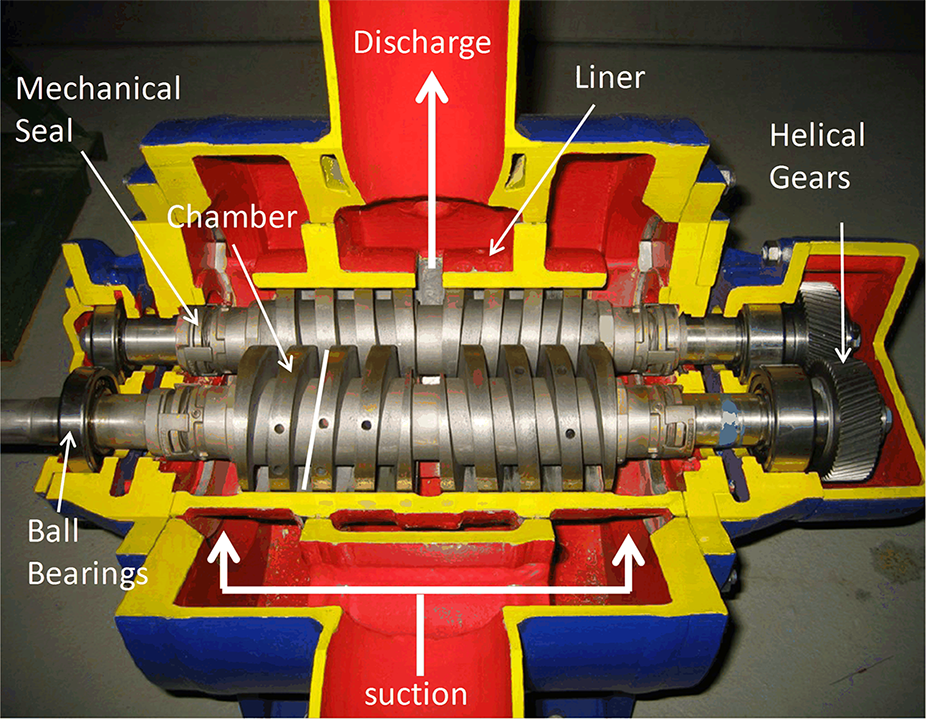

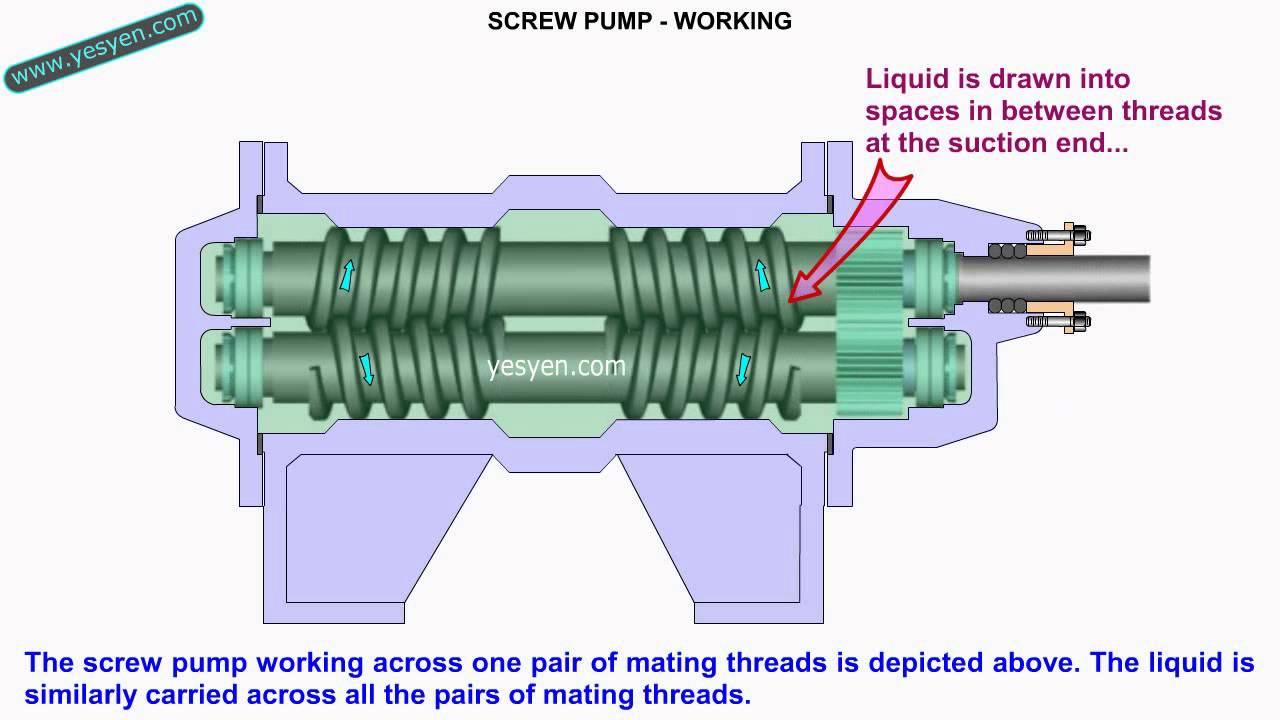

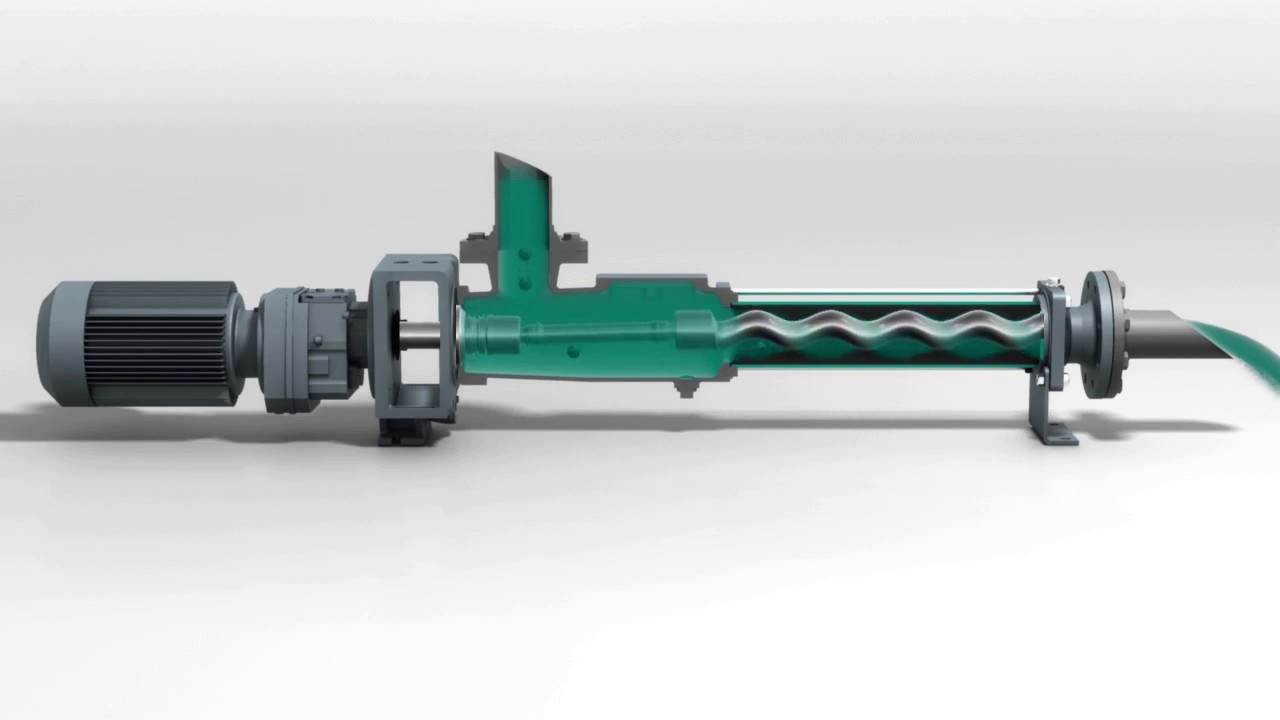

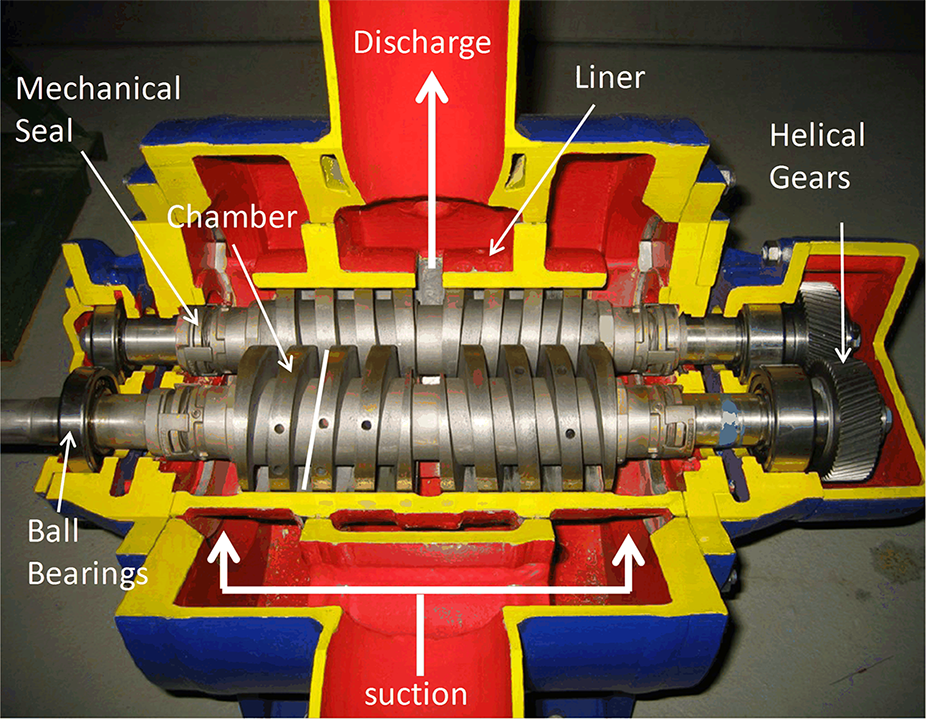

The working principle of the screw pump varies completely to that gear pump, here the driver screws and the driver revolves in line by the utilization of timing gear. Both the screws that are functioning through a fine clearance pull in air trapping internal to the fine clearance of interlocking screw strings. The screw pump combines many advantageous features of other pump solutions: Like the centrifugal pump, for example, it has no pressure or suction valves, and like a piston pump, the eccentric screw pump also has excellent pumping speed. The flow rate is constant and speed-dependent. Working principle: How do screw pumps work? Screw pumps operate using two counter-rotating screw rotors which are engineered so that they rotate "towards each other". This traps the gas in the space between the "screws" of their rotors. The screw pump animation shows how a screw pump works using a double screw pump working model. Simplified extract from detailed course at https://yesyen.com/.

The working principle of screw pump YouTube

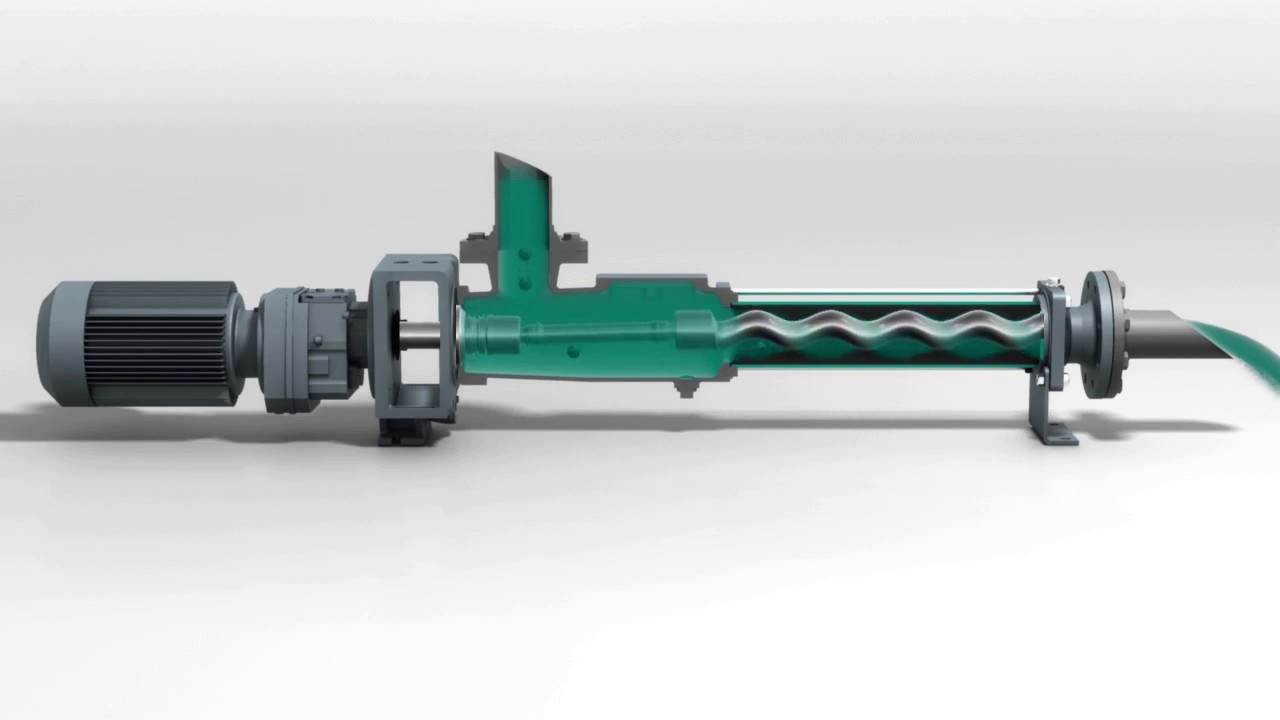

How does a screw pump work? In this video Johannes will talk about the screw pump and explain how it works and where you can use it for.0:00 - Intro0:20 - Ho. February 17, 2022 Post Views: 1,661 What is a screw pump? What is a screw pump? Screw pump is a part of the dry compressed gas transfer pump series. They are positive displacement pumps that use one or more screws to move fluid or water along the screw shaft. These screws interlock to pressurize the fluid and move it into the system. single screw pumps can be greater than 14 feet long. Provided that there is ample physical space available, single screw pumps can be an attractive pumping solution in certain situations. Traditionally, the term "two screw pump" has been applied to a screw pump with two shafts. However, a two screw pump can Working Principle of a Screw Pump. The screw pump is a type of positive displacement pump. As a result, the liquid is consistently displaced from the space it occupies. In order to drive the screw pump, two counter-rotating screws are used. In this case, the rotating screws are set in such a way as to rotate toward each other..

1.3 Screw Pump Educational Revolution

Screw Pumps are designed with the same principles as a Positive Displacement Pump, where a vacuum is created inside the pump to draw out to the discharge sid. A screw pump is a subset of positive displacement pump that use one or more than one screw; to perform pump action along its spindle axis. The complete assembly consists of two main parts; the driving motor ( prime mover ) and the pump assembly.

Screw Pump Working Principle The working of the screw pump is when this pump is pushing thick fluid, and then the screws can be connected strongly with no permission, as the faces are being lubricated like the liquid is pumped. Rotary screw pumps have ex-isted for many years and are manufactured around the world. More demanding ser-vice requirements impose chal-lenges on screw pump manu-factures to provide higher pres-sure or flow capability, better wear resistance, improved cor-rosion resistance and lower leakage emissions. Better materials and more precise

Screw Pump Their Parts, Working And Function ShipFever

A screw vacuum pump is a highly efficient device used to create a vacuum. These pumps operate on a simple principle of intermeshing screws rotating in opposite directions. As the screws rotate, air or gas is trapped and compressed between them, causing the pressure to decrease. Principle. When a pair of meshing screws are used to increased pressure of oil, It is know as screw pump. A screw pump is a type of positive displacement pump that utilizes the rotation of a screw-like rotor to move fluid from one place to another. It is also known as an Archimedes' screw pump, named after the ancient Greek mathematician.