First in first out pallet rack load management. Learn more today! Gravity conveyors for pallet handling can come as single wide roller or twin gravity roller types that have two lanes of narrower gravity rollers. Options like braked rollers and pallet stoppers can be supplied slow or stop pallets down when on a decline. Our gravity pallet conveyors are manufactured from mild or stainless steel.

Automotive company Gravity Roller Conveyors Logistics, Industries CITConveyors

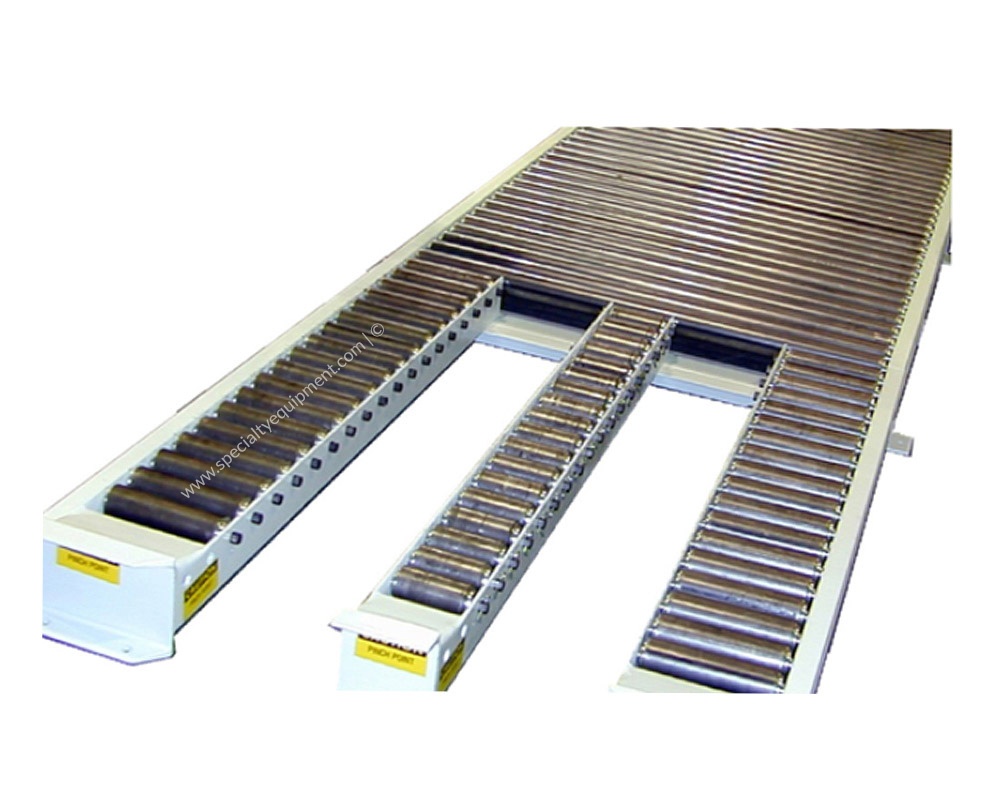

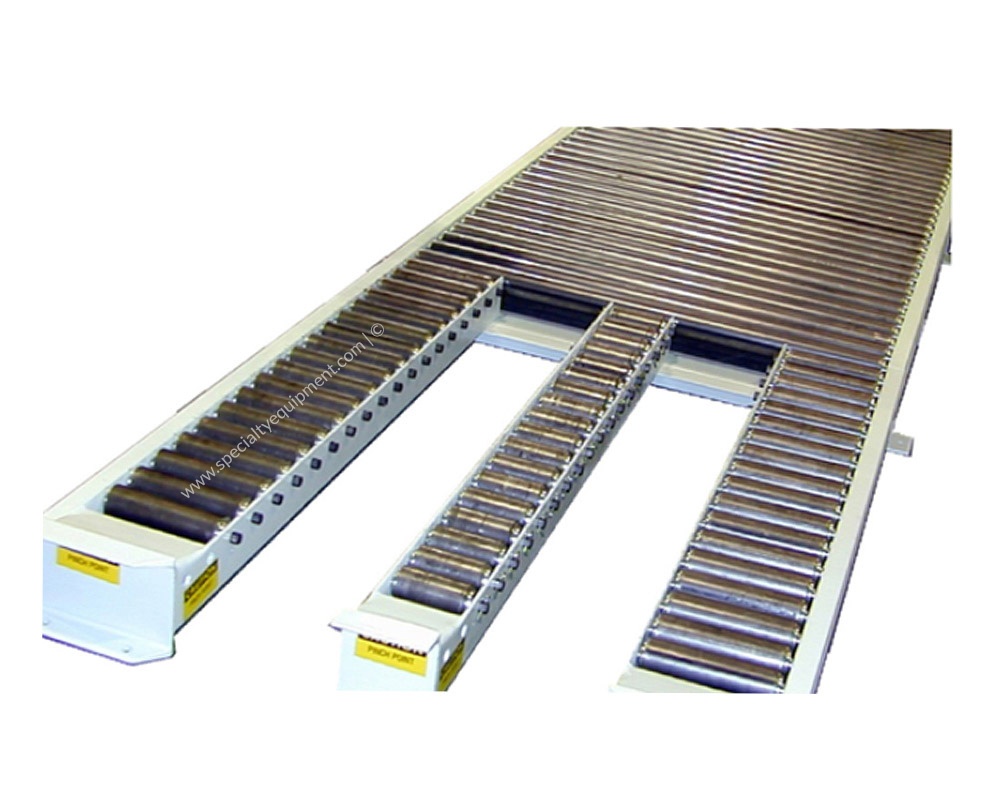

The 900 Series Gravity Conveyor is a heavy-duty roller conveyor, often referred to as a pallet handling conveyor, as that is its most popular application. Fully welded construction complete with rolled steel angle side members make it perfect for a more rugged environment. The rollers are assembled with drilled & wired axles for maximum strength. As UK conveyor manufacturers Spaceguard supplies a robust range of driven rollers, in addition to chain-driven and gravity pallet conveyors. From stand alone conveyor modules to fully integrated conveyor systems. You can expect low levels of maintenance, due to the especially robustly manufactured equipment. Gravity roller pallet conveyors offer the most cost effective pallet handling they require no power supply are quickly and easily installed available in full width or multi lane. Powered roller conveyor systems are required where pallets have to travel greater distances and it is not practical to have a decline or automation is required. Gravity conveyor: the dynamic pallets storage. Dynamic pallet storage is used to optimize the number of pallets stored in an allocated space, while minimizing handling and costs. Our gravity conveyors allow FIFO management ("first in first out") while ensuring a perfectly controlled inventory rotation.

Gravity Conveyor for Pallet Jacks Specialty Equipment

The 900 Series Gravity Conveyor is a heavy-duty pallet-handling conveyor with fully welded construction and rolled steel angle side members. The rollers are assembled with drilled & wired axles for maximum strength. The conveyor length, width and pitch are manufactured to suit the customer's specific requirements. With 100's of options based on different frame and roller designs in both gravity and powered versions, manufactured and supplied to you on time.We offer pallet conveyor systems from narrow multi-lane and low profile floor mounted models right up to specially designed heavy duty gravity and powered roller versions. Gravity conveyors are non-powered and utilize the Earth's gravity to move products. They provide an economic material handling solution and are easy to install and relocate since they do not contain motorized parts. These conveyors use rollers or ball transfer tables to transport items. Conveyor systems for pallets are available in various forms (such as Gravity Pallet Conveyor), and in general are capable of handling loads of up to 1,500kg (higher loads are possible). These solutions are built to suit the pallet types being handled, and the orientation of the pallet when travelling along a system, is critical to the selection of the various technologies.

Pallet gravity roller conveyor Troostwijk

Pallet Gravity Roller Conveyor (or Non-Driven Pallet Roller Conveyor), is a cost effective way to improve pallet handling efficiency. Around the UK, various pallet types are used to move goods. Most commonly used types are standard Euro and UK pallets. Designed for moving and handling heavy loads, pallet conveyors optimize handling operations for manufacturing, warehouse and distribution centers. Bastian Solutions integrates first-class technology that fits the unique requirements of your process to get operations running smoothly and efficiently.

The popular 700 series gravity conveyor is a formed steel side frame with spring loaded rollers, offering a smooth aesthetically pleasing side frame. For maximum versatility speedtrack is available in modular straight sections, bends, spiral bends, gates and merges. All units can be linked to the ocon gravity and powered ranges. Sort by Default. Pallet Conveyor Solutions Most standard pallets are in the 2,500-pound range, but Russell Conveyor Chain Driven Live Roller Conveyors can move loads up to 4,000 pounds. This is an excellent option if you need to move heavy pallets and still want the benefits of Motor Driven Roller (MDR) technology.

Pallet Conveyor System Stoecklin US

The most cost-effective conveying solution. Gravity roller conveyors are the most economical and simplest form of transporting loads from one point to another. Minimal effort required in the movement of goods whether it is manual assistance or gravitational force. Gravity Conveyor Applications. Gravity conveyors are designed with either aluminum or steel rollers, depending on the size and weight of the objects being transported, with heavier-duty applications utilizing a chain-driven system. You can floor-mount your conveyor or raise the conveyor line to a comfortable, ergonomically supportive height.